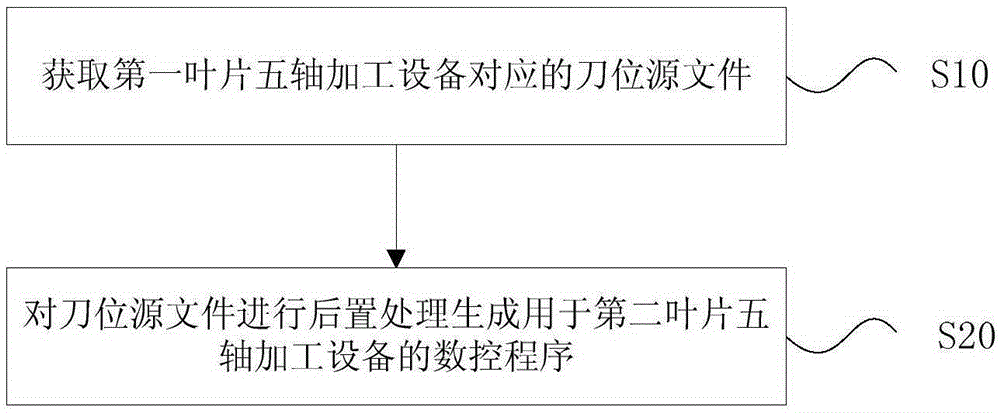

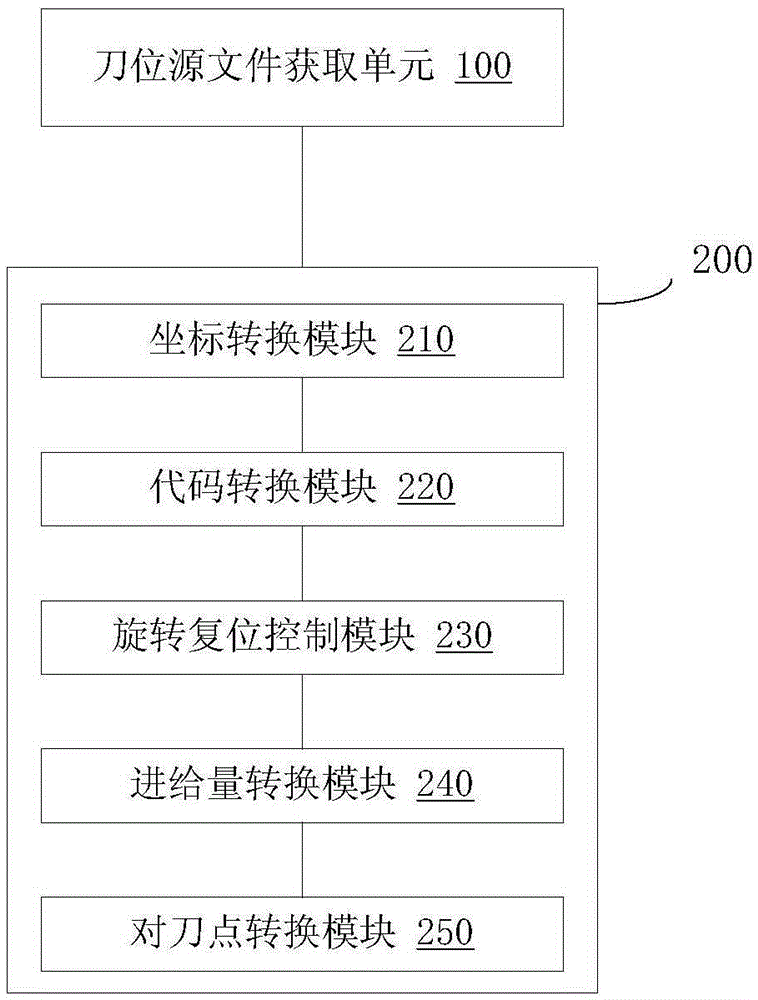

Blade five-axis machining programming processing method and device

A processing method and processing device technology, applied in the direction of program control, electrical program control, instruments, etc., can solve the problems of low processing efficiency and waste, and achieve the effects of improving efficiency, reducing workload and saving procurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Take the go-Mill350 blade five-axis machining center program post-processing with TNC530 as the control system and dual-rotating table as an example, including:

[0075] (1). Read the tool location source file.

[0076] (2) Processing of comment sentences. Treat the comment statement as a statement with the symbol ";" and write it into the NC program file.

[0077] (3). Processing of tool change character segment. Extract the tool number and tool change character segment and write it into the NC program file.

[0078] (4). Spindle speed S and rotation direction character segment processing: extract the spindle speed S and rotation direction character segment and write it into the NC program file.

[0079] (5) Processing of machine tool motion statements:

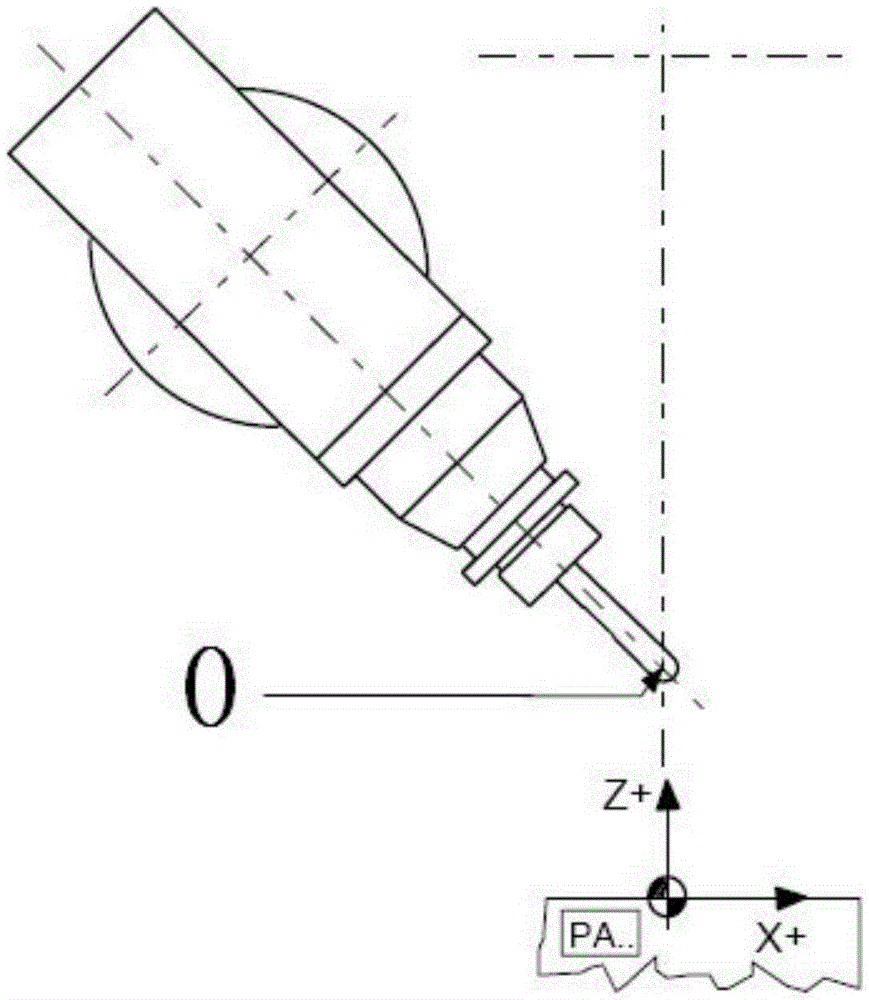

[0080] ●Extract tool position coordinate values X, Y, Z and tool axis vector coordinate values I, J, K in the machine tool motion statement;

[0081] The APT code format is as follows, where each data represents X, Y, Z, I,...

Embodiment 2

[0121] Take the A156 blade five-axis machining center program post-processing with the control system E580 and the structure of a turntable + a swing head as an example, including:

[0122] (1). Read the tool location source file.

[0123] (2) Processing of comment sentences. Put the comment statement in the bracket "()" and write it into the NC program file.

[0124] (3). Processing of tool change character segment. The tool number and tool change character segment are extracted, processed as comment sentences, and written into the NC program file.

[0125] (4). Spindle speed S and rotation direction character segment processing. Extract the spindle speed S and rotation direction character segment and write it into the NC program file.

[0126] (5). Processing of the tool information character segment. Extract the tool tip fillet character segment ToolRadius, and write the tool tip fillet value into the Cr variable.

[0127] (6) Processing of machine tool motion statements.

[0128] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com