Production line layout method facing manually assembled product

A layout method and manual assembly technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of reduced production capacity of the assembly line and unsystematic design, so as to improve production capacity, avoid duplication of labor, and balance the load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

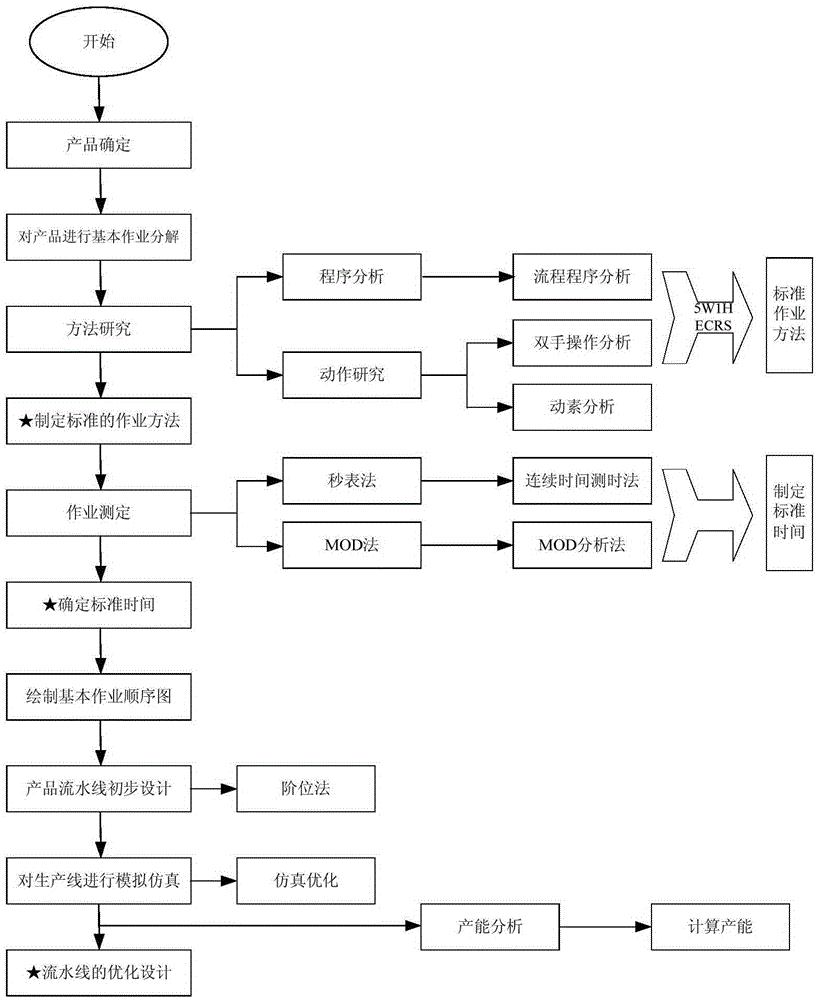

[0023] Embodiment 1 A kind of assembly line layout method for manual assembly products described in the present invention comprises the following steps:

[0024] 1) Determine the product object, and decompose the basic operation of the product;

[0025] 2) Analyze the logical relationship before and after the basic operations, draw the basic operation sequence diagram, that is, apply method research to analyze the basic operations, and formulate standard operation methods; the method research includes program analysis and motion research, and the analysis of the two-handed operation and kinetic elements used in the motion analysis analyze;

[0026] 3) Carry out time research on the operation method by applying the operation measurement to determine the standard operation time; the operation measurement includes the stopwatch method and the MOD method; if the stopwatch method is used, the continuous time measurement method for the product object is required;

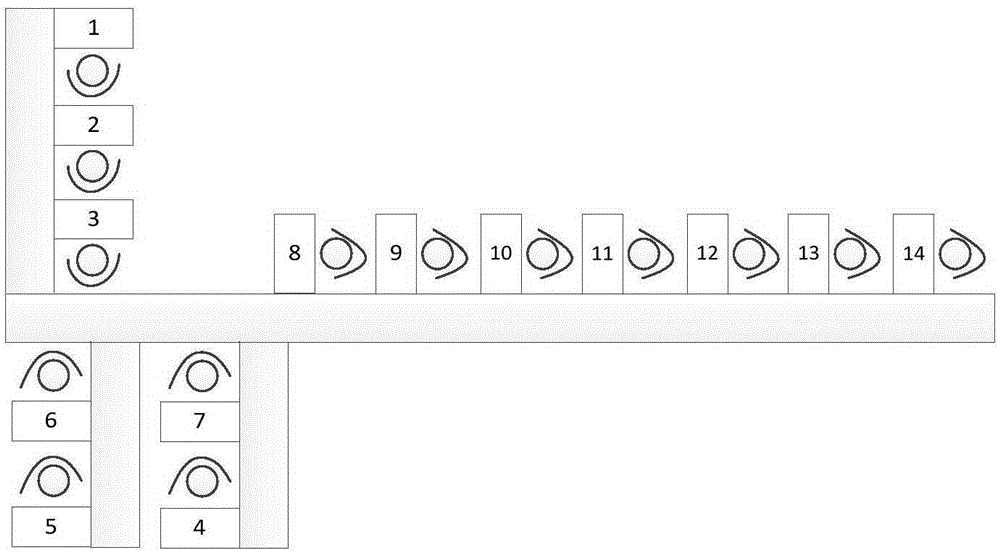

[0027] 4) Accord...

Embodiment 2

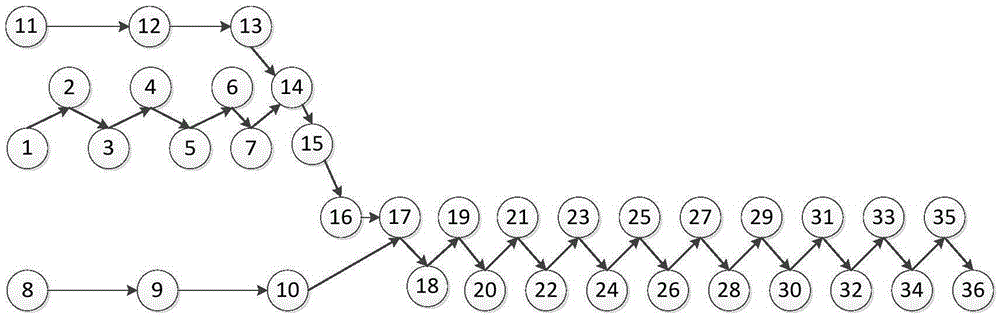

[0032] Embodiment 2 Determine the product according to step 1) of the method in Embodiment 1, and decompose it into basic operations. Taking the assembly line design of an electric hammer as an example, the assembly operation of the electric hammer is decomposed into 36 basic operations, as shown in Table 1 shown.

[0033] Table 1 The assembly operation of the electric hammer is broken down into 36 basic work tables

[0034] serial number

[0035] 36

Embodiment 3

[0036] Embodiment 3 according to the step 2) of the method for embodiment 1) carry out method research

[0037] Conduct method research on 36 basic operations, that is, carry out detailed process program analysis, two-handed operation analysis, kinetic element analysis, and MOD analysis; we take one of the basic operations (serial number 4, assembling the piston assembly) for detailed analysis. The method research of other basic operations can refer to the analysis method of the bottleneck station for method research.

[0038] (1) Flow program analysis - assembly of piston parts

[0039] Table 2 Process program analysis—worksheet for assembling piston components

[0040]

[0041] (2) Movement research

[0042] Table 3 Analysis of Two-handed Operation—Assembling the Piston Assembly

[0043]

[0044] Table 4 Kinetic Analysis—Assembled Piston Assembly

[0045]

[0046] The above-mentioned two-handed operation analysis table and kinetic element analysis table for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com