A pressure ring for a submerged arc furnace with a cleaning port

A submerged arc furnace and pressure ring technology, which is applied in the direction of electric heating devices, heating through discharge, electrical components, etc., can solve the problems of increasing maintenance difficulty, water hardness cannot be lowered, and water flow is not smooth, so as to reduce the maintenance work of workers Quantity, reduce heat stop time, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

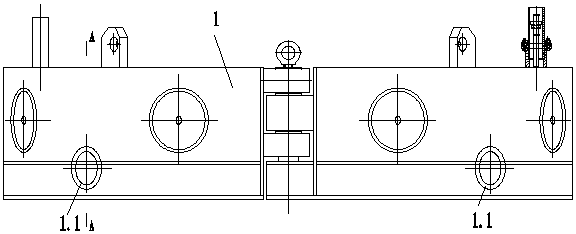

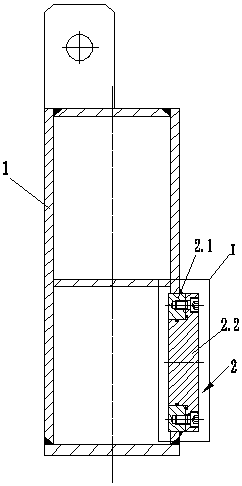

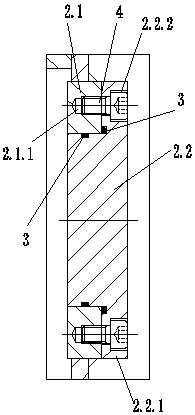

[0012] Embodiment 1: a kind of submerged arc furnace pressure ring containing the decontamination port comprises two pressure semi-annular bodies 1, and the side wall near the bottom of the semi-annular body 1 is provided with 2 decontamination ports 1.1, and the decontamination port 1.1 A sewage discharge device 2 is arranged on it, and the sewage discharge device 2 includes a sleeve 2.1 and a gland 2.2. The sleeve 2.1 is embedded in the cleaning port 1.1, and is welded and fixed on both sides along the contact surface of the two. The top of the gland 2.2 There is a ring of flange 2.2.1, the lower end is connected with the inner hole of the sleeve 2.1, and the contact surface between the lower end of the gland 2.2 and the inner hole of the sleeve 2.1 is provided with an O-ring 3 in the radial and axial directions. Type sealing ring 3 is embedded in the notch that offers on gland 2.2. The distance between the center of the cleaning port 1.1 and the bottom surface of the half-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com