Surface mount path optimization algorithm and high-speed surface mount machine based on algorithm

A path optimization and placement machine technology, which is applied to the assembly of printed circuits with electrical components, printed circuits, and printed circuit manufacturing, can solve the problems of no further improvement and limited development space, so as to improve picking efficiency and wide application range , the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

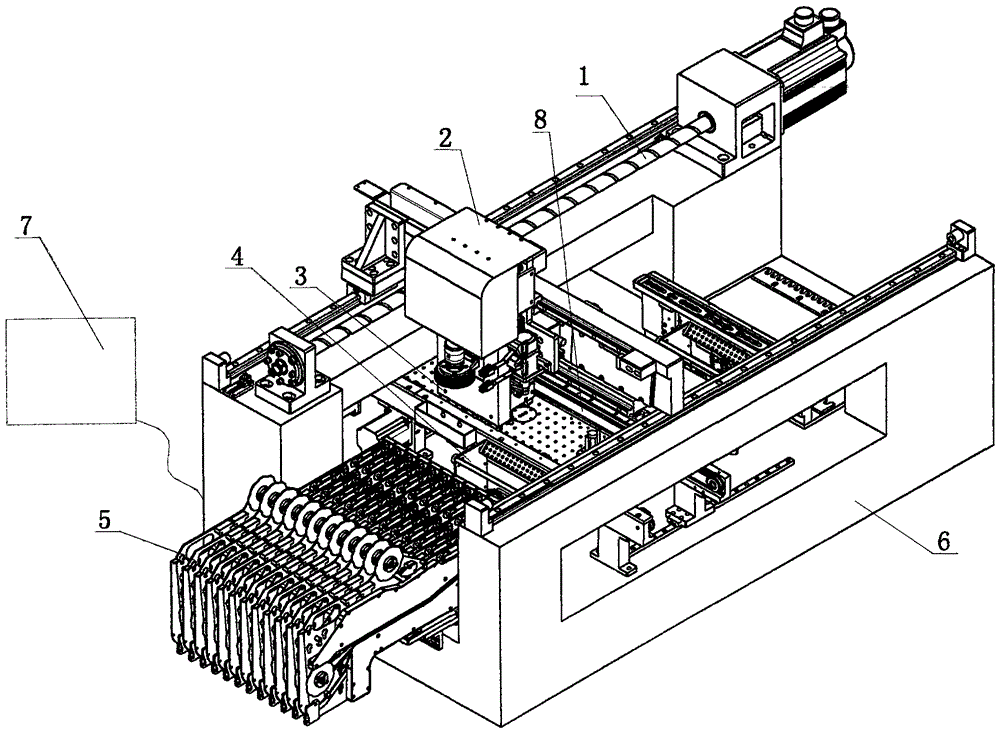

Image

Examples

Embodiment Construction

[0029] The center of the present invention is: with the optimization algorithm as the core, combined with the shortest path algorithm, the installation position of the automatic feeder is calculated and determined, so that in the process of picking up the components to be mounted, the quick picking and mounting under the shortest stroke are formed. , in order to reduce the running time of the placement head and reduce the wear of the transmission system, combined with the corresponding hardware structure improvement, to ensure the efficient and accurate completion of the placement process.

[0030] A mounting path optimization algorithm according to the present invention, the specific steps include:

[0031] Step 1. The chip mounter controller collects the size information of the circuit board to be mounted and the type, quantity and distribution information of the components to be mounted.

[0032] In actual production, the placement information of each circuit board to be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com