Roll buckle forming machine

A forming machine and buckle technology, which is applied in the field of packaging parts processing, can solve the problems of complex structure, high cost, and easy damage, and achieve the effects of good stability, low cost, and large bending force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

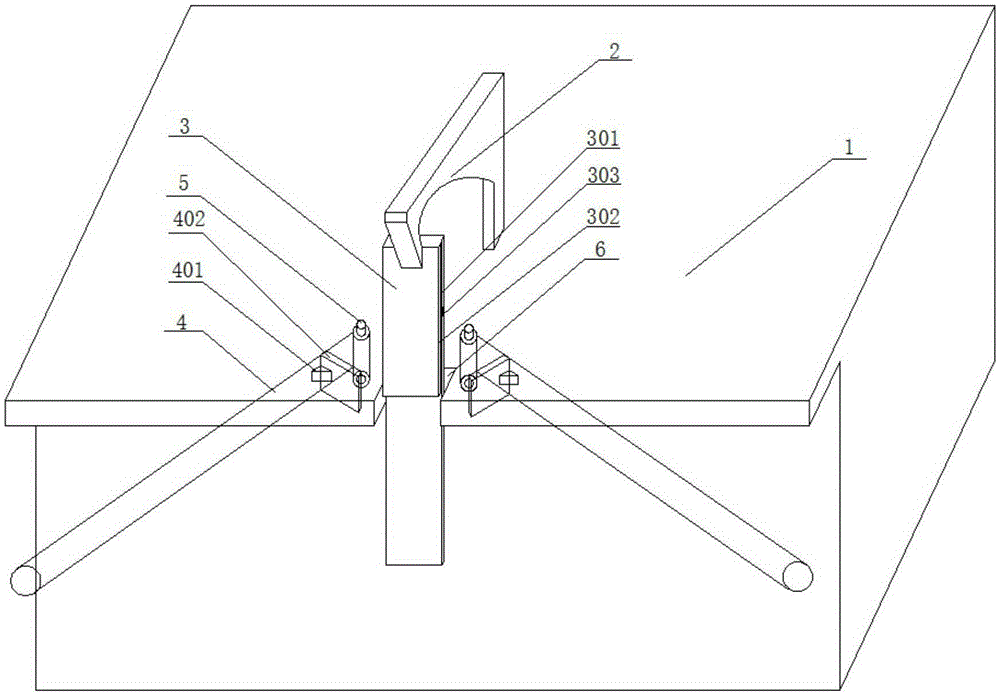

[0027] A buckle forming machine, including a workbench 1, a support frame 2, a buckle clip 3 and a handle 4, wherein the top side of the workbench 1 protrudes from the overall table surface, and the center of the raised part is provided with an inward concave Clamping groove 6, four movable wheels are arranged near the four corners at the bottom of the workbench 1 . The workbench can be easily moved, suitable for different occasions, convenient and fast.

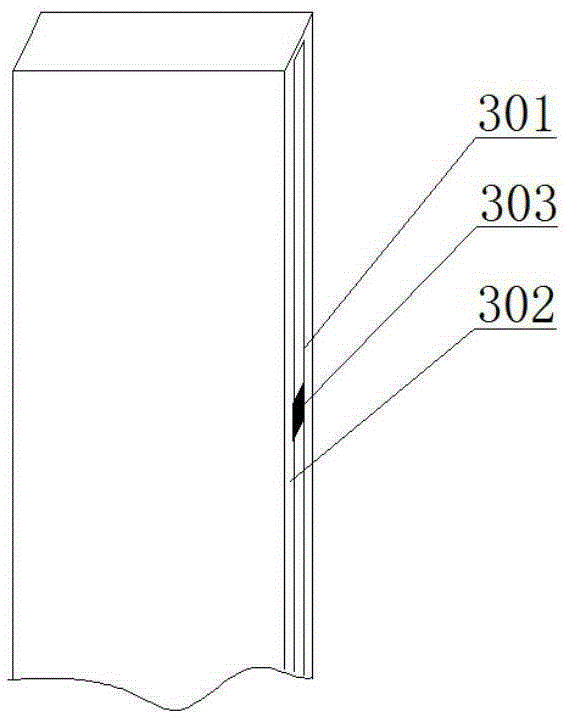

[0028] The buckle 3 includes a front clip 301 and a rear clip 302, the length of the rear clip 302 is 1.5 times that of the front clip 301, and the tops of the front clip 301 and the rear clip 302 are connected to each other, and the buckle 3 The upper part forms a gap between the front clip 301 and the rear clip 302. The width of the gap is slightly thicker than the thickness of the buckle steel sheet that needs to be bent, so that the buckle steel sheet can be smoothly inserted into the gap for bending. The middle part of...

Embodiment 2

[0032] A buckle forming machine, including a workbench 1, a support frame 2, a buckle clip 3 and a handle 4, wherein the top side of the workbench 1 protrudes from the overall table surface, and the center of the raised part is provided with an inward concave Clamping groove 6, four movable wheels are arranged near the four corners at the bottom of the workbench 1 . The workbench can be easily moved, suitable for different occasions, convenient and quick.

[0033]The buckle 3 includes a front clip 301 and a rear clip 302, the length of the rear clip 302 is twice that of the front clip 301, and the tops of the front clip 301 and the rear clip 302 are connected to each other, and the buckle 3 The upper part forms a gap between the front clip 301 and the rear clip 302. The width of the gap is slightly thicker than the thickness of the buckle steel sheet that needs to be bent, so that the buckle steel sheet can be smoothly inserted into the gap for bending. The middle part of one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com