Flexible ultrasonic punch micro deep drawing die and edge pressing gap adjustment and measurement method

A flexible punch and micro-drawing technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of being crushed and drawing deviation, so as to improve the unbalanced force and avoid drawing deviation of the workpiece Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

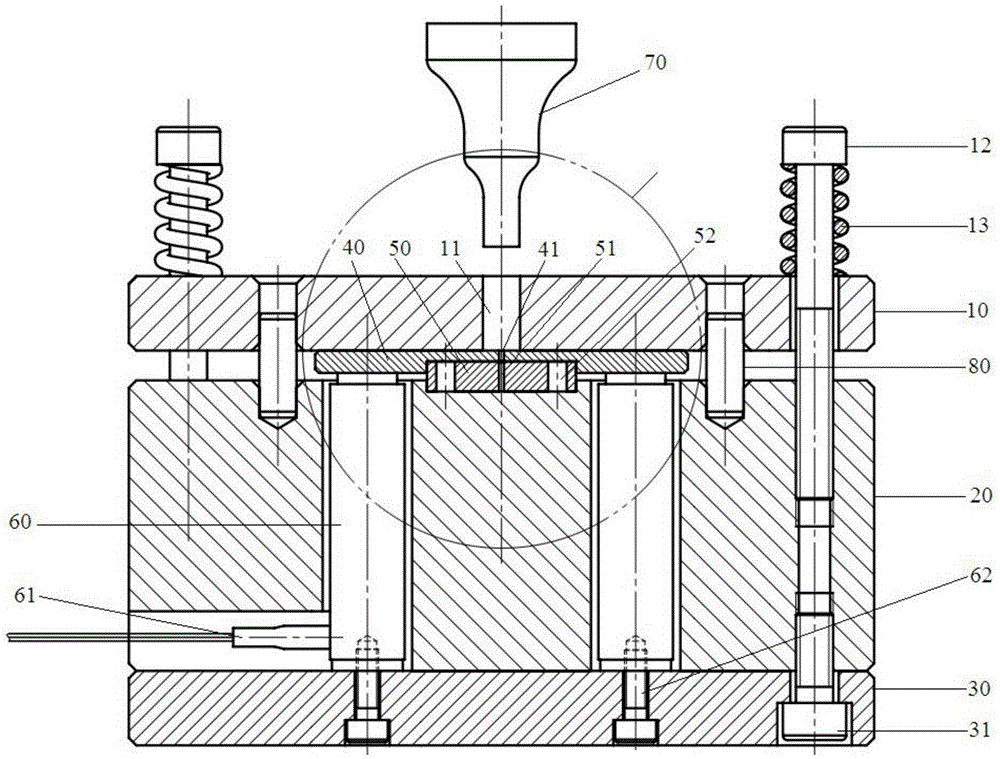

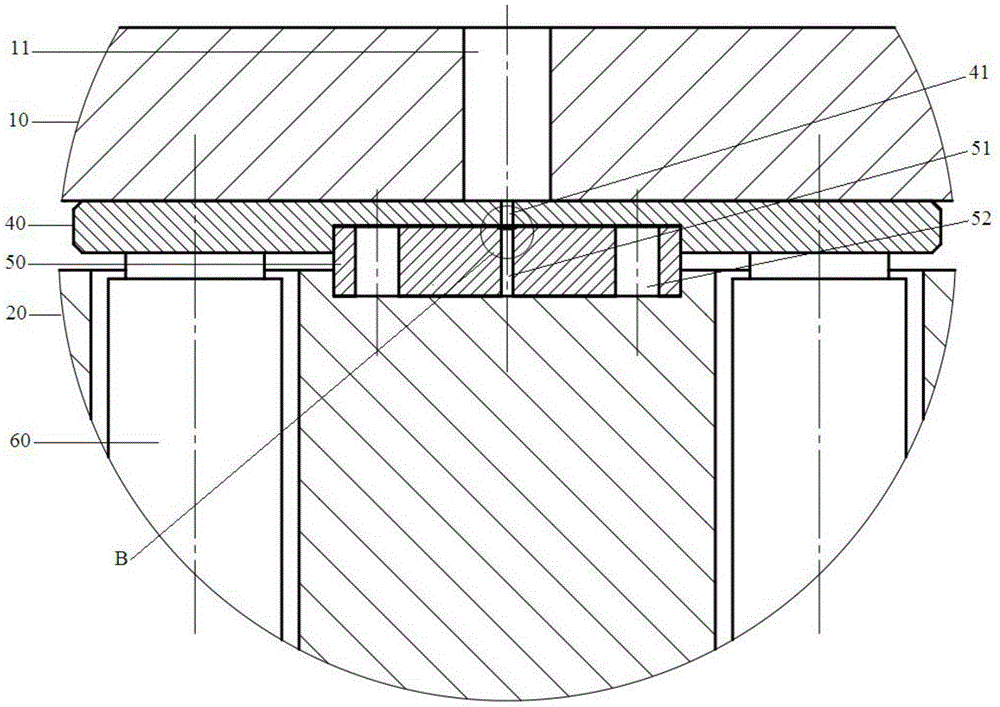

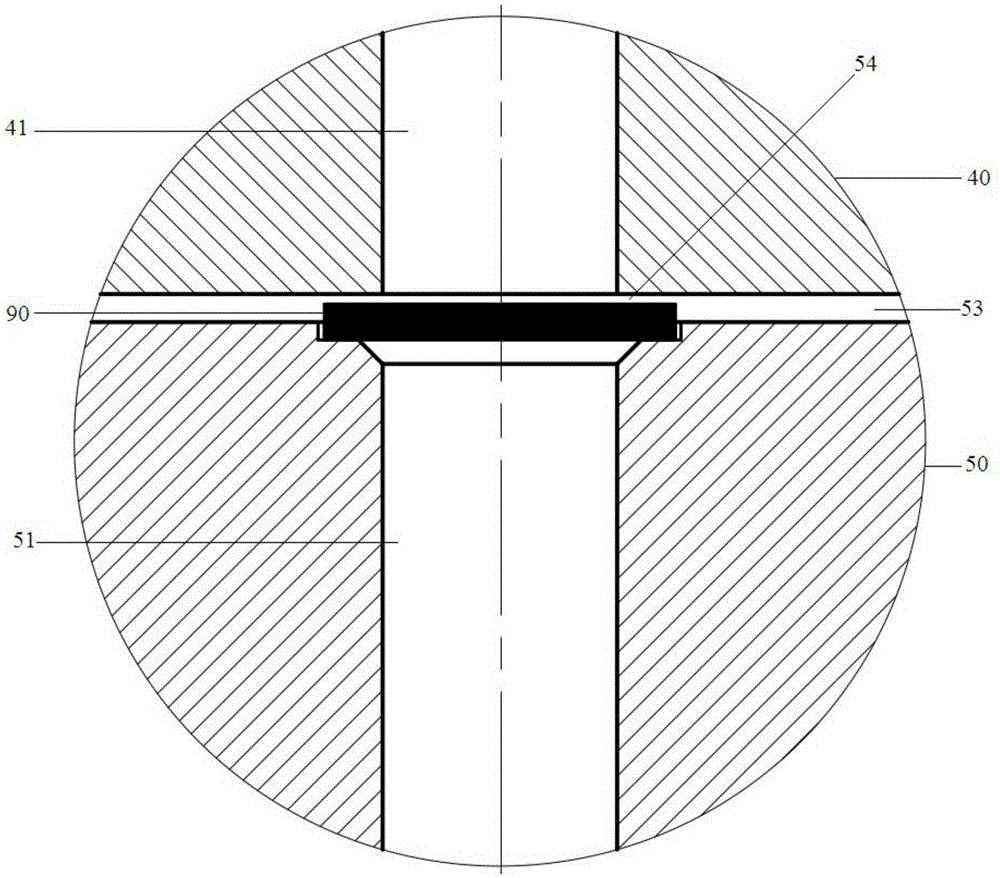

[0031] refer to Figure 1 to Figure 3 , the embodiment of the present invention proposes a flexible punch ultrasonic micro-drawing die, including a pressure plate 10 , a middle plate 20 , a bottom plate 30 , a blank holder 40 , a deep-drawing die 50 and a micro-motion actuator 60 .

[0032] The center position of the top surface of the above-mentioned middle plate 20 is provided with a drawing die positioning groove, and the drawing die 50 is arranged in the drawing die positioning groove, and the drawing die positioning groove can ensure that the drawing die 50 is positioned on the middle plate. Accurate positioning on 20.

[0033] A cavity 51 is set at the center of the drawing die 50, and a blank positioning frame is set at the top of the cavity 51, wherein the blank positioning frame ensures that the drawing blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com