Welding method of ultrathin metal parts

A welding method and ultra-thin metal technology, applied in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory sealing welding effect and increasing welding difficulty, and achieve the effect of small deformation and reliable welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: A kind of welding method of ultra-thin metal parts

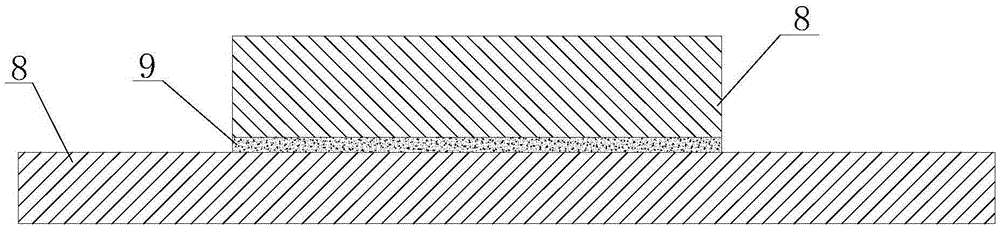

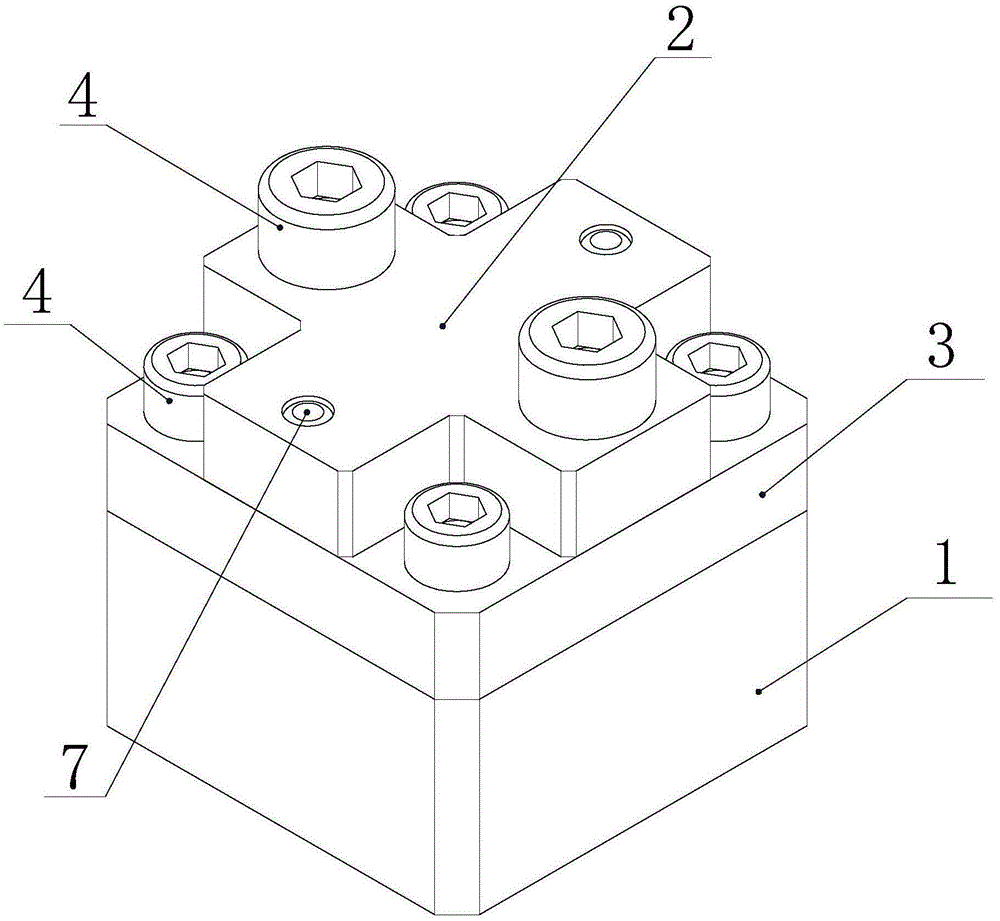

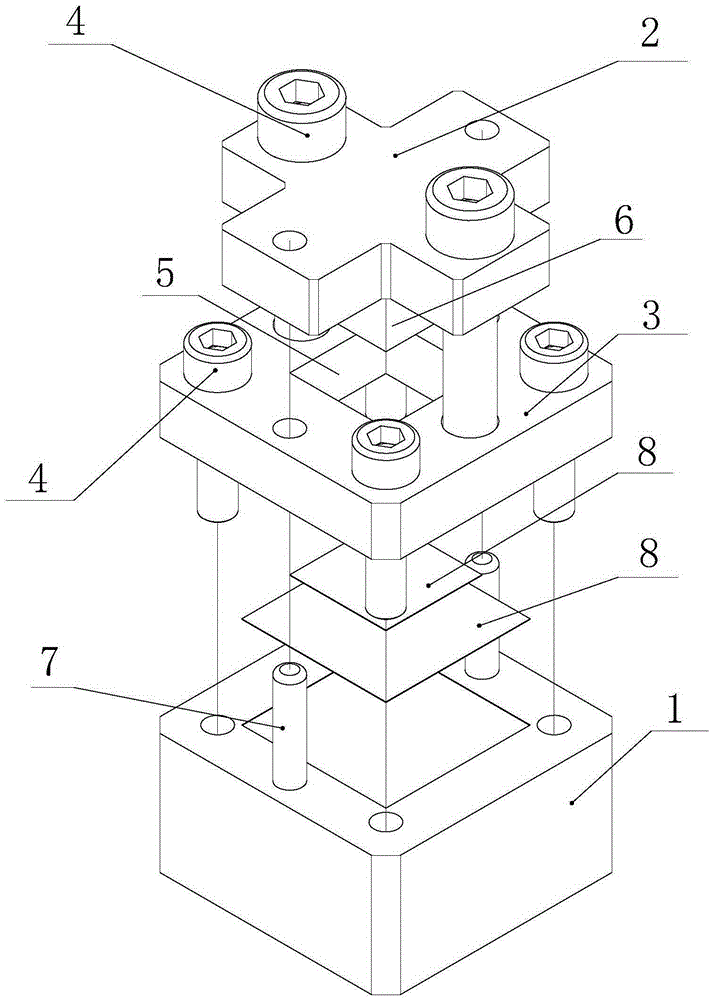

[0017] See attached figure 1 , attached figure 2 And attached image 3 As shown, a welding method for ultra-thin metal parts, the welding method includes a jig, the jig includes a jig base 1, a briquetting block 2 and a pressing plate 3; The bearing platform for welding metal parts 8, the jig base 1 is affixed to the pressure plate 3 through the compression screw 4; the pressure plate 3 is provided with a compression block through hole 5, and the pressure block 2 corresponds to the pressure plate 3 The through hole 5 of the pressing block is provided with a pressing block 6, and the pressing block 2 is fixedly connected with the pressing plate 3 through the pressing screw 4; the welding method comprises the following steps: placing two metal parts 8 to be welded on the On the carrying platform, the solder paste 9 is coated between the two metal parts 8 to be welded, and then the fixture base 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com