Automatic welding walk car of inner ring welding line

A walking trolley and automatic welding technology, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the inner ring seam cannot be welded automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in further detail below in conjunction with embodiment.

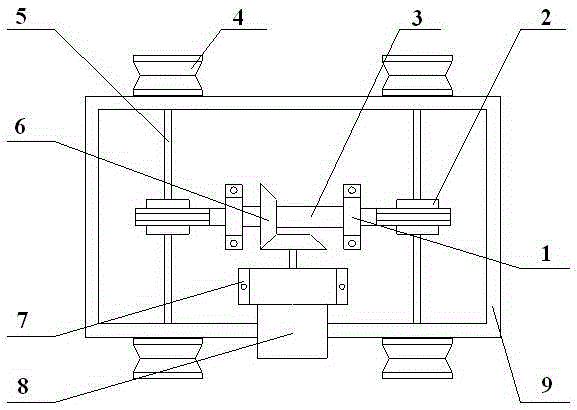

[0011] See figure 1 , Boiler inner circular seam automatic welding walking trolley, welding walking trolley includes walking wheel 4, motor 8, pressure plate 7, worm shaft 3, support 1, walking trolley frame 9, worm wheel 2, wheel shaft 5 and bevel gear 6, in the walking trolley The bottom of the frame 9 is equipped with a worm shaft 3, the worm shaft 3 is connected with the motor 8 through the bevel gear 6, and the motor 8 is fixed on the bottom of the trolley through the pressure plate 7; the two ends of the worm shaft 3 are equipped with a support 1, and the support 1 Worm wheel 2 is installed, and wheel shaft 5 is installed on the worm wheel 2, and the two ends of wheel shaft 5 are equipped with traveling wheel 4.

[0012] When the motor 8 starts, it drives the bevel gear 6 to rotate, and the bevel gear 6 drives the worm shaft 3 to rotate, and the worm shaft 3 drives the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com