Abrasion-resistant ball rust removal device

A wear-resistant ball, the same technology, applied in the field of wear-resistant balls, can solve the problems of increased dust, blockage of the body, large quantities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

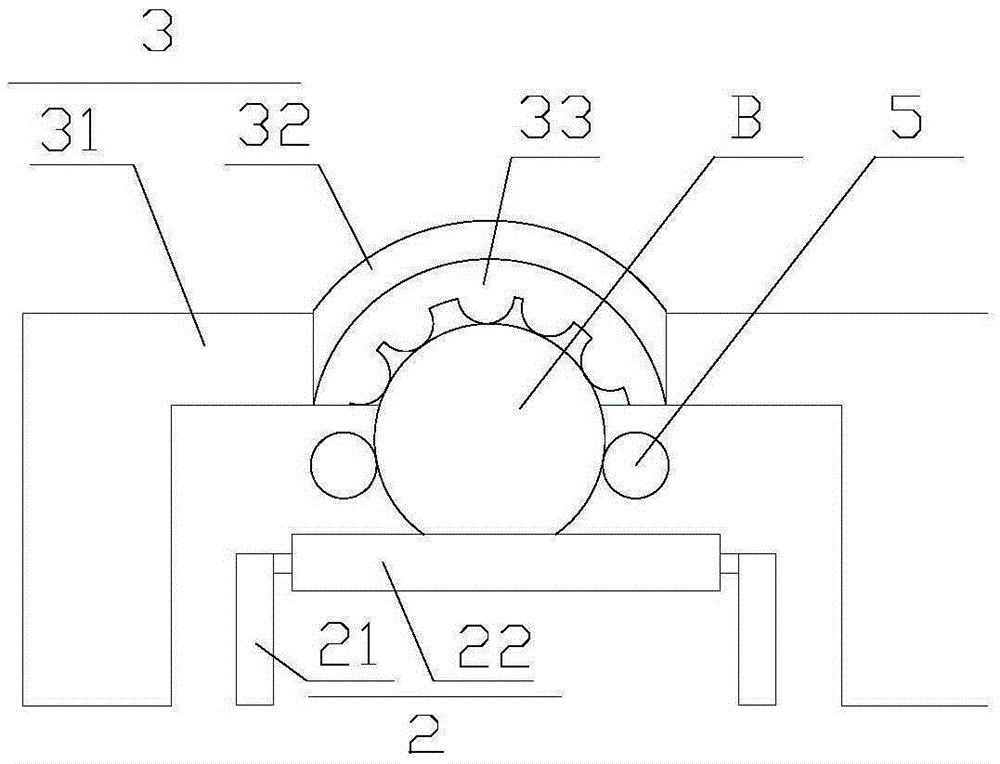

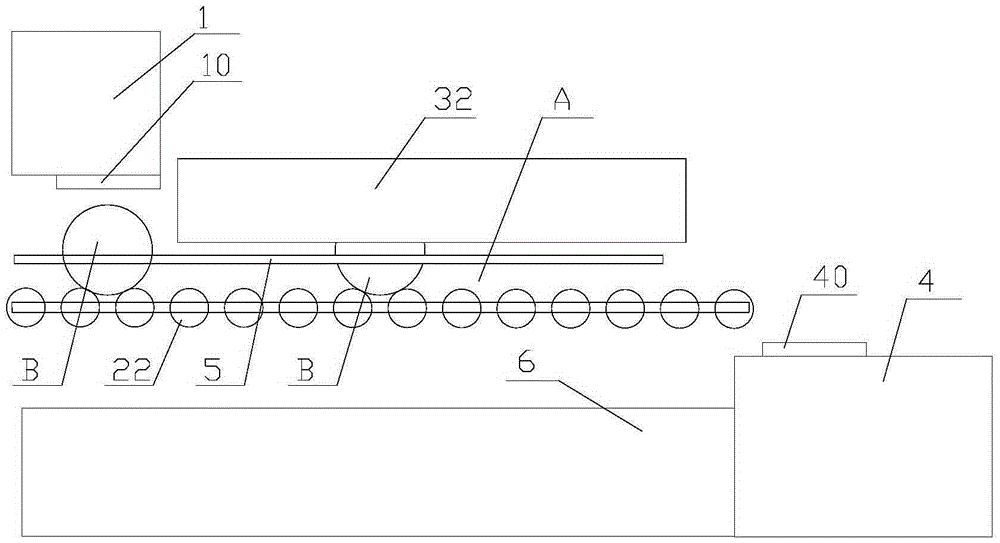

[0023] refer to figure 1 , figure 2 , a wear-resistant ball derusting device proposed by the present invention includes: a hopper 1, a transport part 2, a grinding part 3 and a collection box 4.

[0024] The transportation part 2 includes a first mounting frame 21 and a plurality of turning rollers 22 . A plurality of rotating rollers 22 are mutually parallel and rotatably installed on the first installation frame 21 , and are located on the same plane to form a transportation channel A.

[0025] The hopper 1 and the collecting box 4 are respectively installed at the feeding end and the discharging end of the transportation channel A. The bottom of the hopper 1 is provided with a discharge port 10 corresponding to the feeding end, so as to transport the wear-resistant balls B in the hopper 1 to the transportation channel A. The collecting box 4 is provided with a feeding port 40 corresponding to the feeding end, and the wear-resistant balls B on the transport channel A can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com