EPE pasting machine

A technology for pasting machines and retrieving mechanisms, applied in lamination devices, packaging, lamination, etc., can solve problems such as low safety, low pasting precision, and low efficiency, and achieve personal safety protection, compact structure, and improved accuracy rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

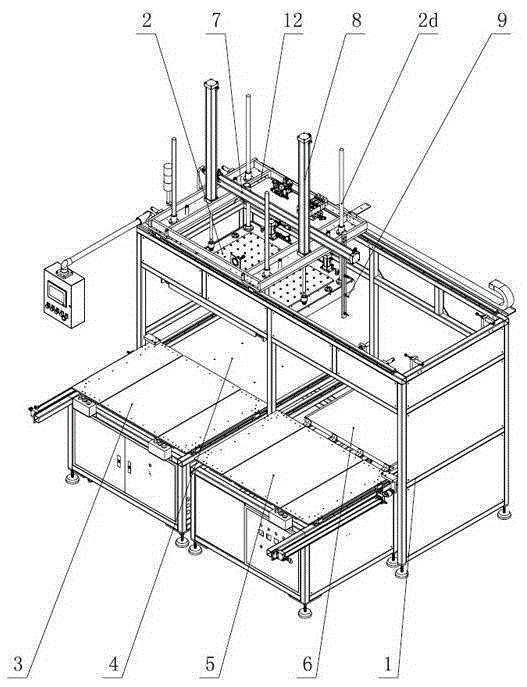

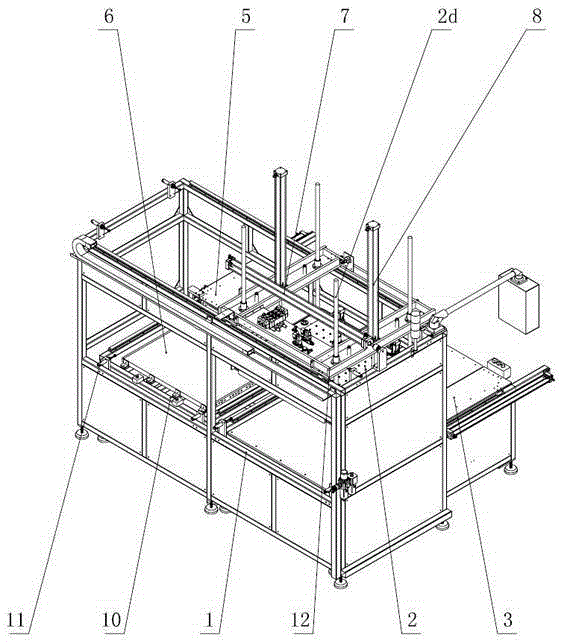

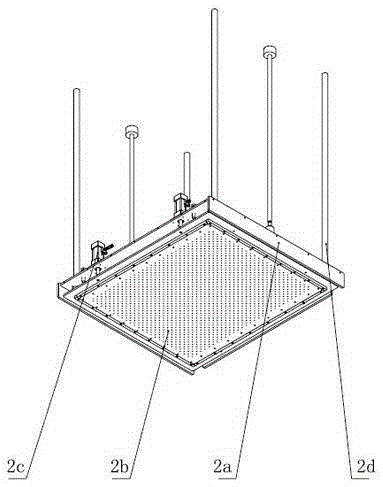

[0025] like figure 1 , figure 2 As shown, the EPE pasting machine includes a gantry 1, a retrieving mechanism 2, a first station and a second station. The first station and the second station can be set independently of each other and arranged side by side under the gantry 1.

[0026] The first station includes auxiliary material preset station 3 and upper auxiliary material station 4 which are set before and after. The auxiliary material preset station 3 is provided with an auxiliary material preset device, and the upper auxiliary material station 4 is provided with a plane workbench. First slide rails are arranged on the left and right sides, and the auxiliary material preset device can re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap