Fluorination bottle having two-solution quantitative mixing function

A technology for quantitative mixing and fluoridation of bottles, which can be used in containers with multiple items, caps with auxiliary devices, sealing parts with auxiliary devices, etc., which can solve the problems of liquid contamination in the main bottle, lack of secondary barriers, etc. , to achieve the effect of improving barrier protection and improving mixing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

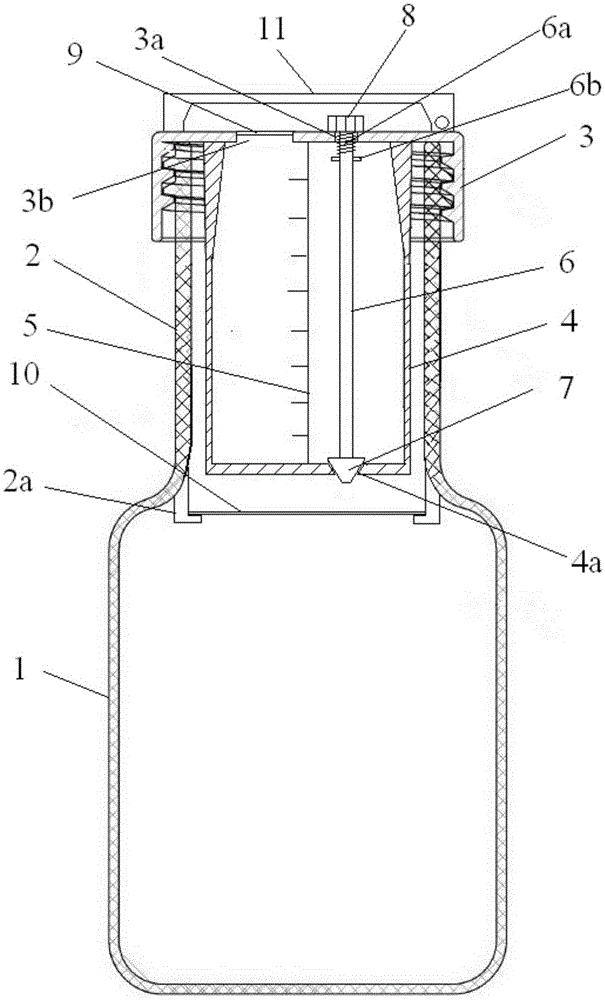

[0019] Example: Combine figure 1 Shown is a specific embodiment of the fluorinated bottle with double-liquid quantitative mixing function of the present invention, which has a main bottle body 1 and a main cover body 3 as in the conventional technology, the top of the main bottle body 1 is a bottleneck 2, and the bottle An external thread is provided on the outside of the mouth 2, and an internal thread is provided on the main cover body 3 to be screwed and connected with the bottle mouth 2. In this example, the main cover body 3 is fixed with an auxiliary bottle body 4 extending into the mouth 2 of the main bottle body 1 , and a scale 5 is marked on the body of the auxiliary bottle body 4 . At the same time, the main cover 3 is provided with an auxiliary bottle body liquid injection hole 3b, and the auxiliary bottle body liquid injection hole 3b is provided with an auxiliary bottle body sealing film 9 .

[0020] The improvement of the present invention is that a drip va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com