Rocker ball seat type hydraulic power flushing and unloading device

A flusher and ball seat type technology, which is applied in the field of pretreatment equipment in the sugar industry, can solve the problems of excessive recoil and inconvenient control of the hydraulic flusher, and achieve the effect of convenient control and wide coverage angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

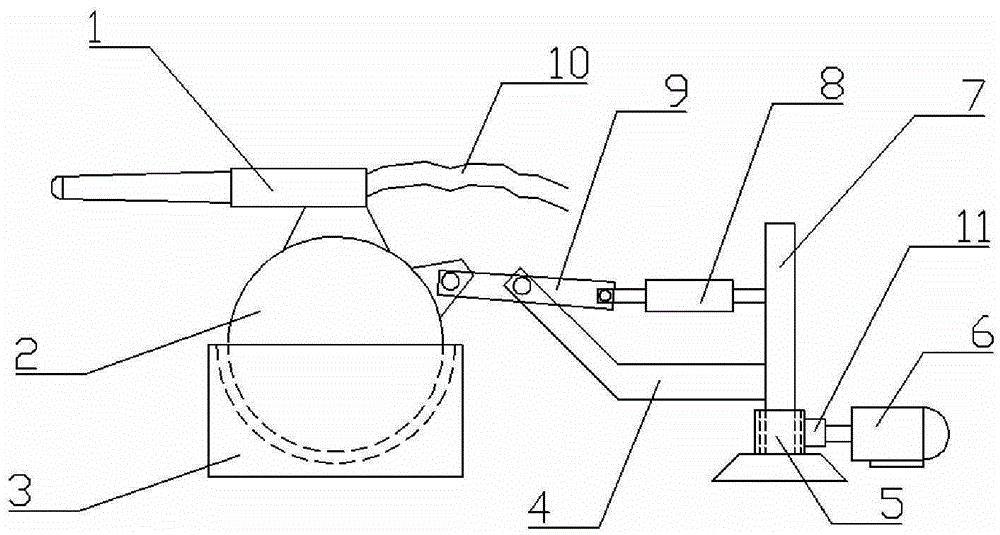

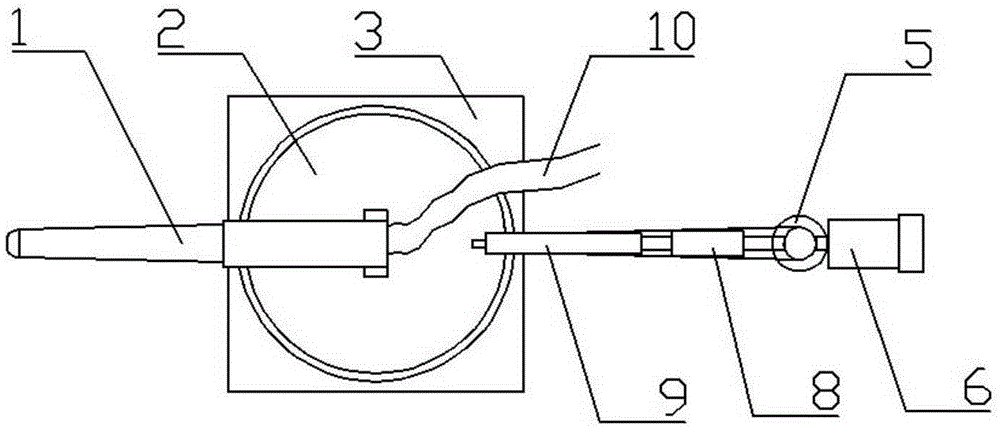

[0023] Embodiment 1: see figure 1 and figure 2 , a rocking ball seat type hydraulic flusher, including a high-pressure spray gun 1, a spherical base 2 and a spherical groove 3, the high-pressure spray gun 1 is installed on the spherical base 2, and the spherical base 2 falls in the spherical groove 3 and can be placed in it Free rolling, the inlet of the high-pressure spray gun 1 is connected to the water inlet pipe 10; it is characterized in that: the spherical base is driven and connected with the mechanical rocker arm, and the mechanical rocker arm includes a support arm 4, a sleeve 5, a motor 6, a rotating shaft 7, The electric telescopic rod 8 and the connecting rod 9; the rotating shaft 7 falls into the sleeve 5 arranged on the ground, and the whole mechanical rocker can rotate vertically around the axis of the sleeve 5 driven by the rotating shaft 7; the rotating shaft 7 is on the side A support arm 4 is extended, and the connecting rod 9 is hinged with the support ar...

Embodiment 2

[0025] Embodiment 2: This implementation is a further improvement made on the basis of Embodiment 1. The difference from Embodiment 1 is that the transmission 11 is a reversing gear set, and the lower end of the rotating shaft 7 is fixed with a reversing gear Set of corresponding gears. The shell of the spherical base 2 is an iron sheet, and the inside is evenly poured with concrete. The high-pressure spray gun 1 is arranged on the top of the spherical base 2, and is fixedly connected with the spherical base 2 through an angle connector of 50 to 80°. The spherical groove 3 and the sleeve 5 are installed on the operating platform near the sugar beet flow ditch. The performance of the hydraulic flusher in this embodiment is stable and the impact range is wide.

Embodiment 3

[0026] Embodiment 3: This implementation is a further improvement made on the basis of Implementation 2, and a remote control method is adopted: the motor 6 and the electric telescopic rod 8 are equipped with a signal receiver and a decoder, and are remotely controlled by the same remote controller .

[0027] The use process of this embodiment is as follows: the rocking ball seat type hydraulic flushing device is installed on the operating platform near the sugar beet flow ditch, the operator holds a remote controller nearby, toggles the motor switch, the motor 6 rotates, and the spherical base 2 circles vertically Rotate the straight axis, toggle the telescopic rod switch, the electric telescopic rod 8 will stretch back and forth, and the spherical base 2 will rotate around the horizontal axis until the required spray angle is adjusted. The flushing water enters the high-pressure spray gun 1 from the water inlet pipe 10, and then impacts the sugar beet pile up. The operator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com