Bridge type concentric polymer distributor for separate-layer polymer injection well

A polymerizer and bridge-type technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems affecting normal polymer injection in other layers, low docking success rate, high labor intensity, etc., to achieve The effect of high docking success rate, short measurement and adjustment cycle, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

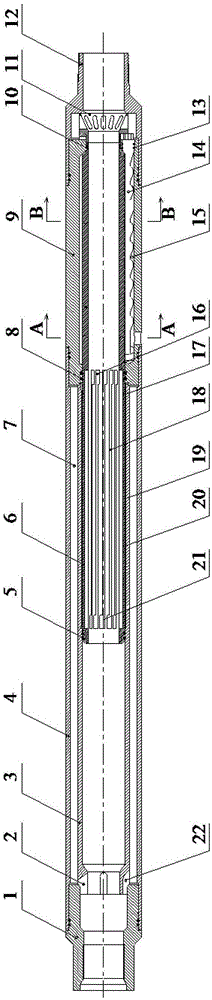

[0029] The embodiment of the present invention provides a bridge-type concentric polymerizer for layered polymer injection wells to solve the problems of low butt joint success rate, long test period, high labor intensity and influence on the normal operation of other layers in eccentric polymerizers. Injection technical problems.

[0030] An embodiment of the present invention provides a bridge-type concentric aggregator, including:

[0031] upper connector;

[0032] The connecting sleeve is connected with the upper joint;

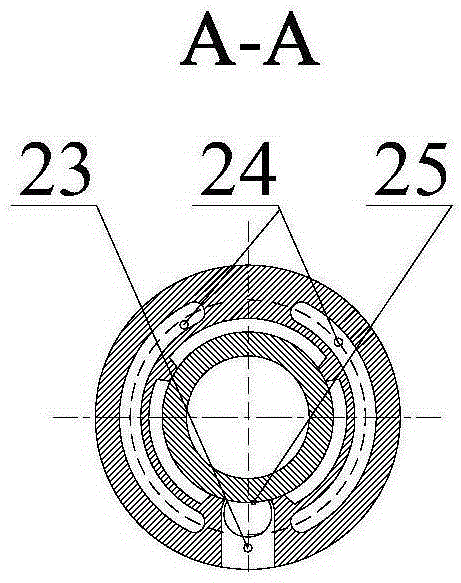

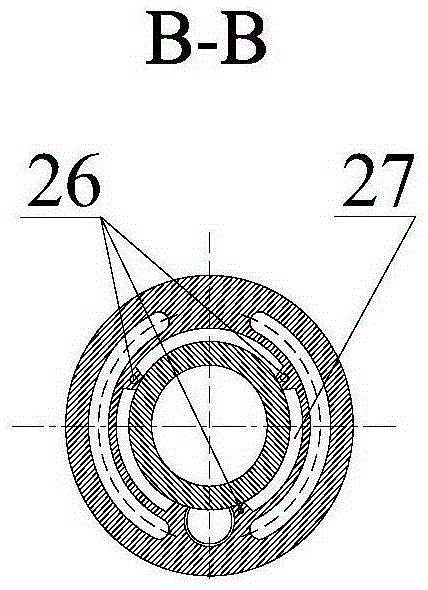

[0033] The positioning platform is set in the connecting sleeve and pressed by the upper joint. The end of the positioning platform close to the upper joint is provided with a positioning groove and a bypass groove. The annular space formed by the positioning platform and the connecting sleeve is a side groove;

[0034] The adjustment sleeve is arranged in the positioning platform and connected with the positioning platform. The end of the adjustment sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com