Method for detecting casing leakage

A leakage detection technology, applied in the field of leakage inspection, can solve the problems of unsmooth construction and inability to accurately judge the location of leakage, and achieve the effect of fast and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

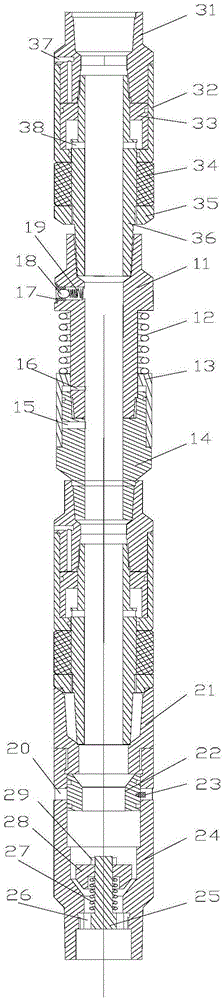

[0007] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. A method for testing casing leakage, including the following steps: Step 1. First, put the casing leakage testing device into the well pipe according to the depth position of the joint collar, and according to the specific position of the joint collar, (generally, oil companies will have each joint collar The specific location data, how many joint collars are in a set of wells, how many meters each joint collar is in the well, these data are kept by the oil company), it is necessary to ensure that the differential pressure opening valve in the leak detection device is near the joint collar, The upper and lower packers are respectively at the upper and lower ends of the hoop, and continuously exert pressure into the center pipe. After the pressure reaches the set value, the floating valve in the combined bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com