Injection molding centrifugal fan blade for air conditioner

A technology of centrifugal blades and injection molding, which is used in parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

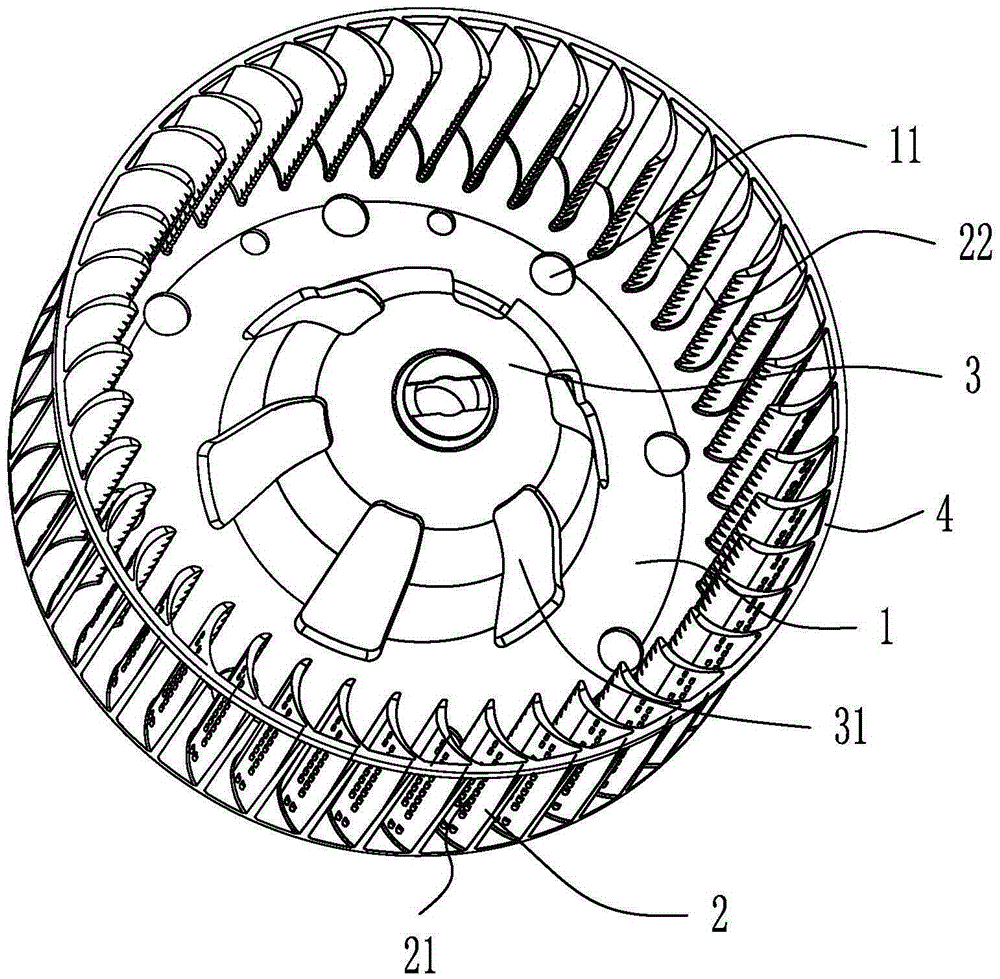

[0010] Attached below figure 1 A detailed description will be made to the specific embodiment of the present invention.

[0011] Such as figure 1 The shown injection-molded centrifugal fan blades for air conditioners include a chassis 1, a hub 3, a plurality of blades 2 and an outer ring 4, the outer side of the hub 3 is connected to the inner side of the chassis 1, and the bottom ends of all the blades 2 are connected to the chassis 1 Connected as a whole, the outer ring 4 is connected as a whole with the outer wall of the top of the blade 2 . The wheel hub 3 is provided with a plurality of material saving openings 31, which further reduces the weight of the product and the cost of production. The number of blades 2 is 43. The center of the centrifugal fan blade, that is, the center of the hub 3 is provided with a motor shaft hole.

[0012] The chassis 1 is provided with 10 material-saving holes 11, and at least two material-saving holes 11 have different areas. The dart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com