A dual power hydraulic system and concrete spraying vehicle

A hydraulic system and dual power technology, which is applied in earthwork drilling, fluid pressure actuators, wellbore lining, etc., can solve the problems of low work efficiency and achieve the effect of high emergency efficiency and free switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

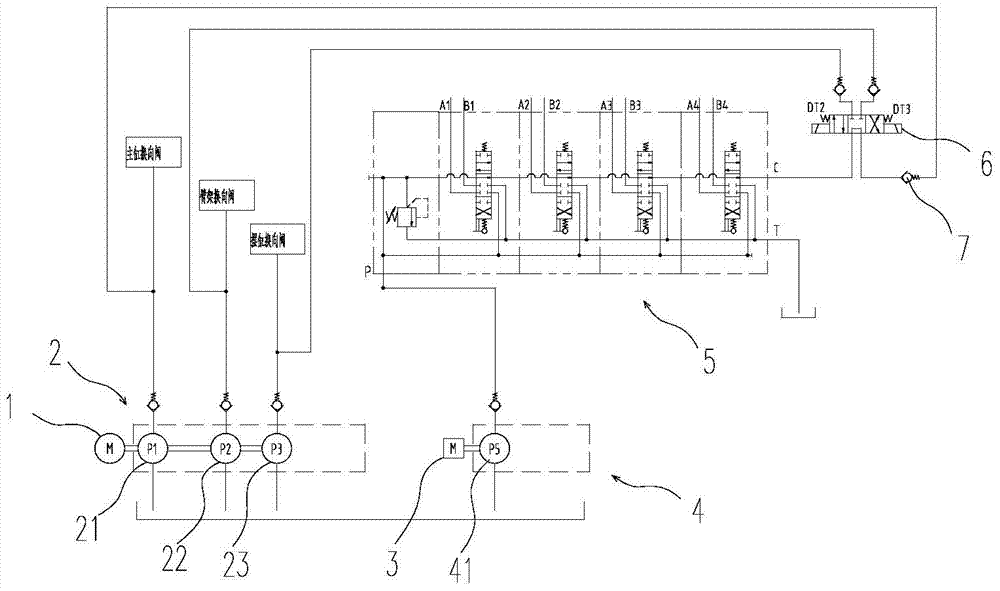

Embodiment 1

[0030] please if figure 1 As shown, the embodiment of the present invention provides a dual power hydraulic system, including the main pump set 2 combined with the main power source 1 and the emergency pump set 4 combined with the emergency power source 3, the main pump set 2 includes, and the main cylinder exchange The first main pump 21 connected to the valve, the second main pump 22 connected to the boom reversing valve, the third main pump 23 connected to the swing cylinder reversing valve; the emergency pump group 4 includes, and the control leg The first emergency pump 41 connected to the oil inlet of the multi-way valve 5; The oil outlet is connected, and the three-position four-way reversing valve 6 is respectively connected with the swing cylinder reversing valve, the boom reversing valve, and the master cylinder reversing valve, so that the first emergency pump 41 can drive the swinging cylinder reversing valve , boom reversing valve and master cylinder reversing va...

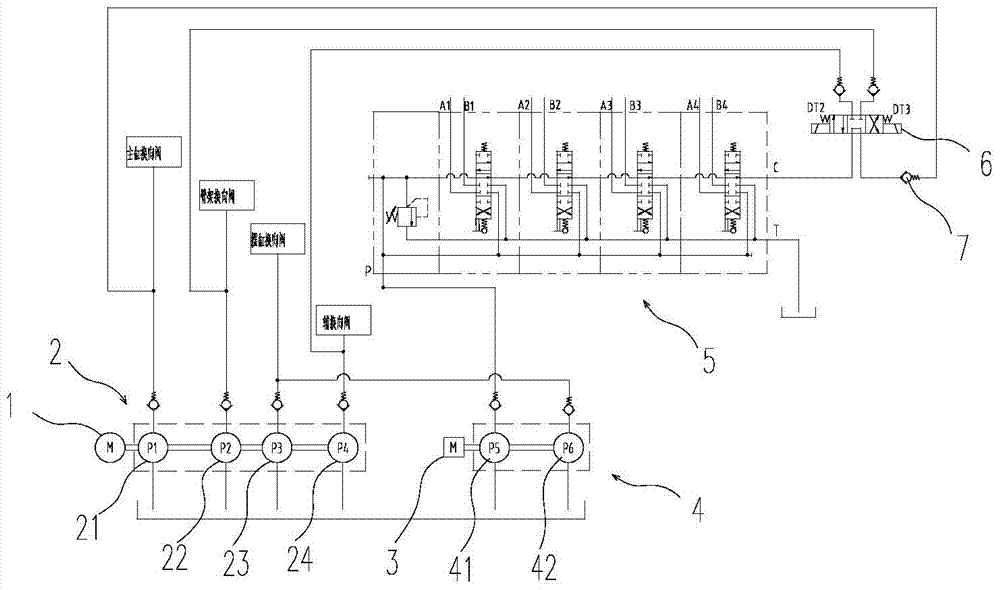

Embodiment 2

[0034] please if figure 2 As shown, the embodiment of the present invention provides a dual power hydraulic system, including the main pump set 2 combined with the main power source 1 and the emergency pump set 4 combined with the emergency power source 3, the main pump set 2 includes, and the main cylinder exchange The first main pump 21 connected to the reversing valve, the second main pump 22 connected to the reversing valve of the boom, the third main pump 23 connected to the reversing valve of the swing cylinder, and the fourth main pump connected to the auxiliary reversing valve 24. The emergency pump group 4 includes a first emergency pump 41 communicated with the oil inlet of the multi-way valve 5 controlling the outrigger, and a second emergency pump 42 connected with the reversing valve of the swing cylinder; the dual power hydraulic system also includes three One-position four-way reversing valve 6, the oil inlet port of three-position four-way reversing valve 6 is...

Embodiment 3

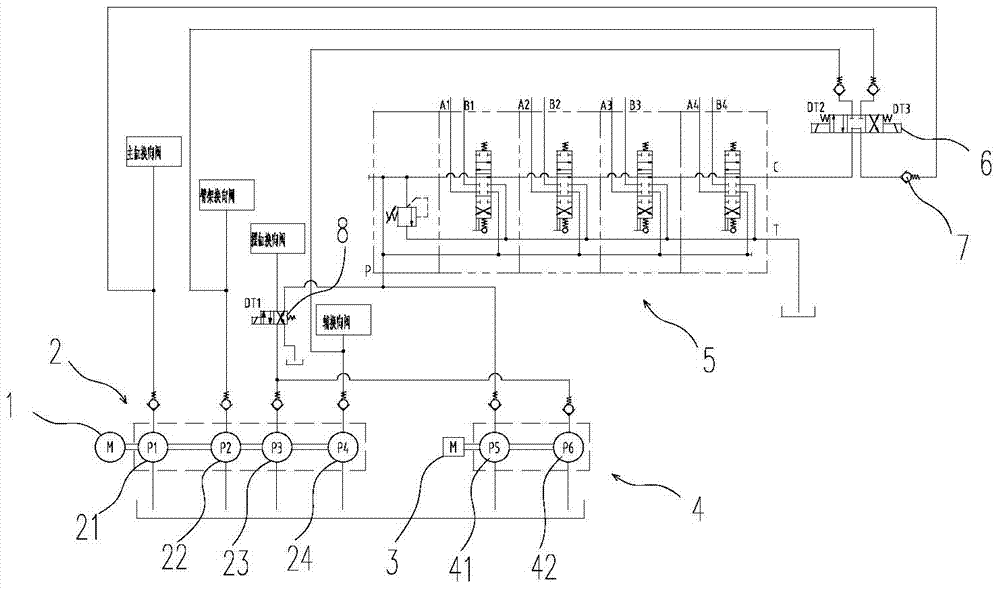

[0041] please if image 3 As shown, the dual power hydraulic system provided by the embodiment of the present invention is compared with the second embodiment, the difference is that

[0042] In the dual power hydraulic system provided by the embodiment of the present invention, a two-position four-way reversing valve 8 is arranged between the check valve of the oil outlet of the third main pump 23 and the reversing valve of the swing cylinder. A working oil outlet of the valve 8 is connected to the second emergency pump 42 .

[0043] The setting of the two-position four-way reversing valve 8 enables the first emergency pump 41 and the second emergency pump 42 to drive the reversing valve of the swing cylinder at the same time, so as to accelerate the reversing valve of the swing cylinder and improve the emergency efficiency.

[0044] The embodiment of the present invention also provides a concrete spraying vehicle, which adopts the above-mentioned power hydraulic system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com