Gap adjusting device for locomotive brake

A technology of clearance adjustment device and brake, applied in the direction of brake type, slack adjuster, mechanical equipment, etc., can solve the problems of insensitive clearance adjustment mechanism, locomotive braking, small brake shoe clearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

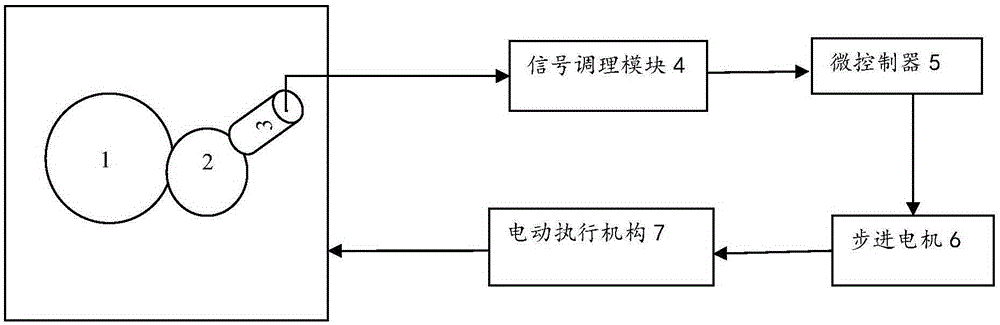

[0018] A brake clearance adjustment device for rolling stock, comprising: a brake shoe 2, a clearance detection device 3, a signal conditioning module 4, a microcontroller 5, a stepper motor 6 and an electric actuator 7, characterized in that the clearance detection device 3. Detect the change of the gap between the wheel tread 1 and the brake shoe 2, and pass the gap value to the microcontroller 5 through the signal conditioning module 4. When the gap changes meet the preset conditions, trigger the stepping motor 6 to drive The electric actuator 7 adjusts the gap between the wheel tread 1 and the brake shoe 2 to realize the gap control of the brake of the rolling stock.

[0019] The electric actuator 7 is used to drive the gap between the wheel tread 1 and the brake shoe 2 to a normal gap setting value of 5-8mm according to the stroke command issued...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com