Method for designing hybrid fiber composite anti-explosion tank

A technology of composite materials and hybrid fibers, which is applied in blasting and other directions, and can solve problems such as the evaluation criteria for the impact resistance of hybrid fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

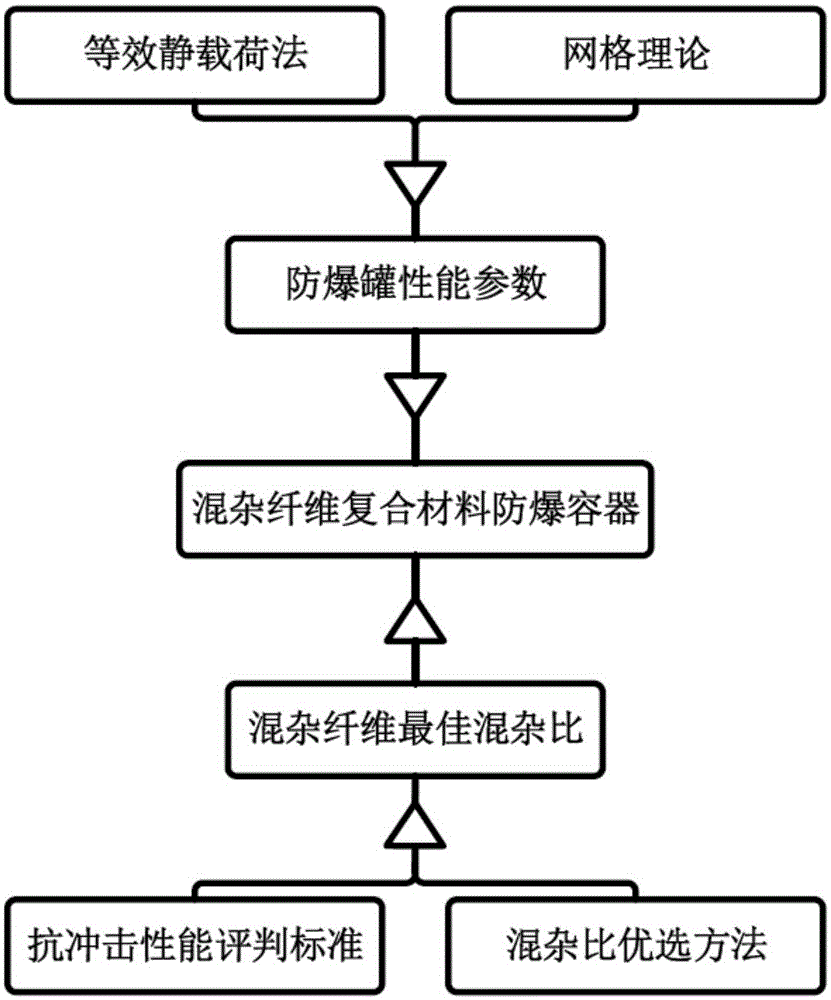

[0103] Such as figure 1 As shown, a hybrid fiber composite material explosion-proof tank design method mainly includes two parts, one is the determination method of the mechanical properties of the explosion-proof tank, and the other is the determination method of the fiber mixing ratio based on the impact resistance performance, and the hybrid fiber is obtained by combining the two Composite material explosion-proof container tank.

[0104] The method for determining the mechanical properties of explosion-proof tanks includes the following steps:

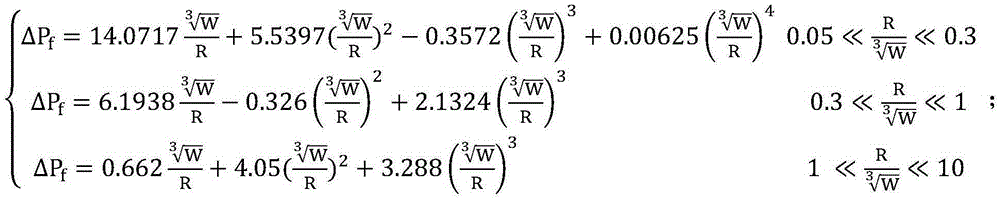

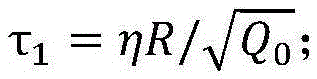

[0105] Citing Hu Bayi's equivalent static load method and cylindrical shell grid theory, the mechanical parameters of the explosion-proof tank can be deduced through the following formulas. Explosion-proof tanks are a special type of pressure vessels that can resist instantaneous high-pressure shocks. When TNT explodes instantaneously, it is very complicated to calculate the explosion process in detail. Therefore, to simplify the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com