A Claus desulfurization and over-control on-line measurement gas cyclone demisting device

A defogging device and gas detection technology, applied in the field of detection instruments, can solve problems such as inability to separate gaseous sulphur and liquid sulphur, affecting the accuracy of gas measurement, and incomplete removal of sulphur, etc. Dehydration effect, improved measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

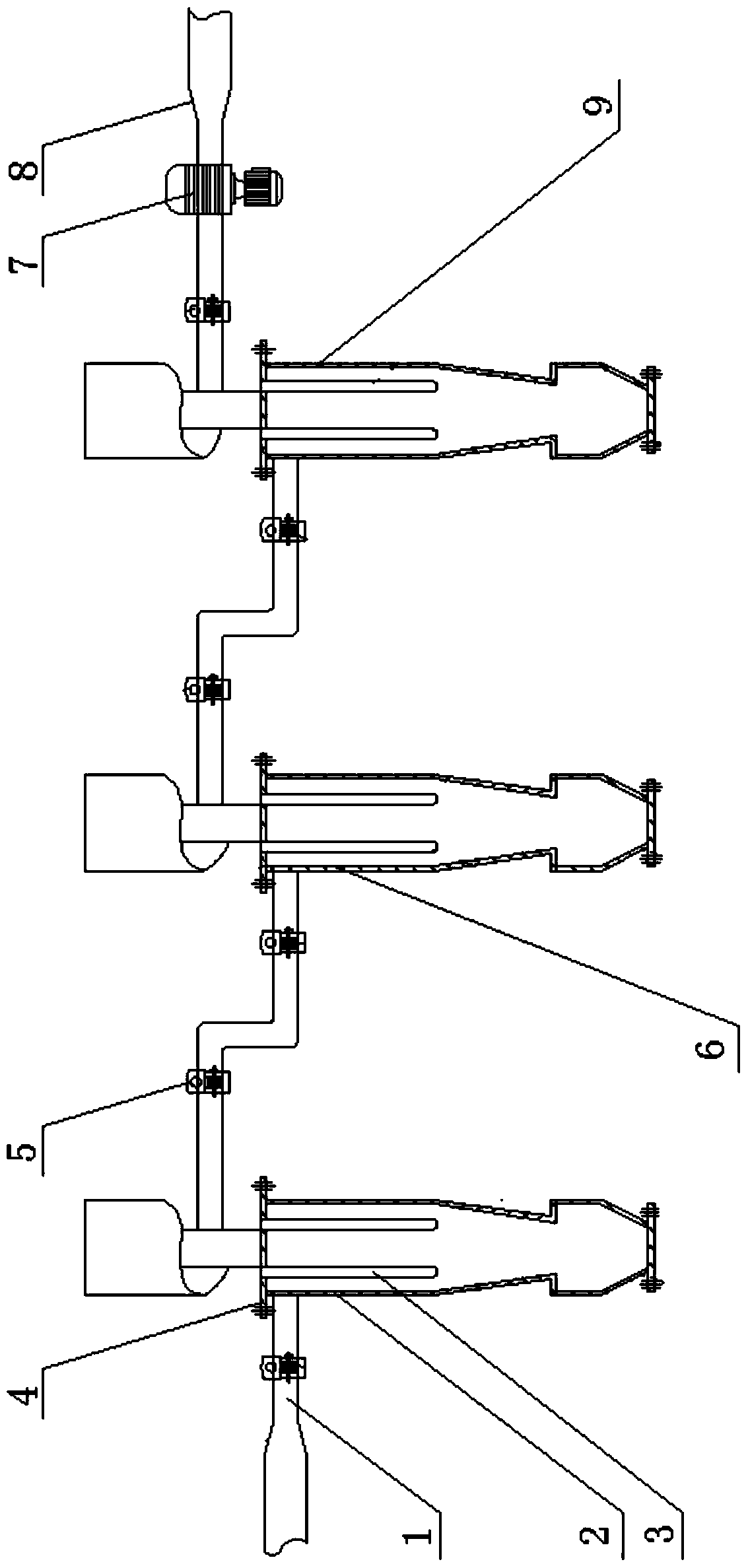

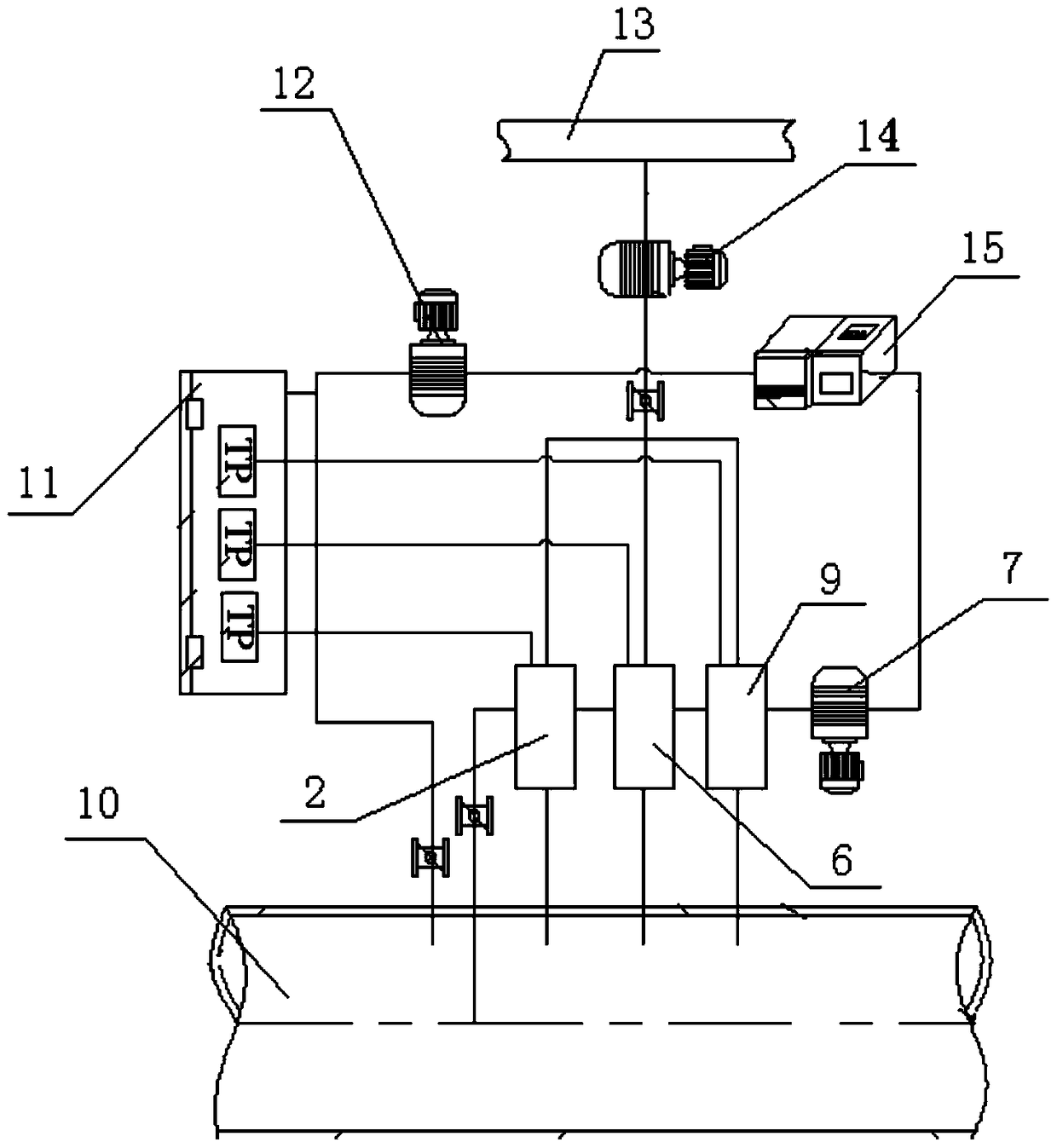

[0052] The embodiment of the present application provides a Claus desulfurization over-control online measurement gas swirl defogging device, which solves or partially solves the incomplete sulfur removal in the thermal desulfurization device in the prior art, and the inability between gaseous sulfur and liquid sulfur. Good separation, the temperature is difficult to control, and the high temperature affects the accuracy of gas measurement. By setting the first temperature control module in the desulfurization cyclone and the second temperature control module in the dehydration cyclone, the detection is realized. The gas is desulfurized and dehydrated efficiently, reducing the interference factors in the process of detecting the gas measurement, realizing the precise control of the temperature of the detected gas through the temperature control module, and improving the technical effect of the accuracy of the measurement results.

[0053] The embodiment of the present applicati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com