Self-balancing loading device for batch concrete-filled steel tubes

A technology of steel tube concrete and loading device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of damage, expensive presses, frequent use, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical scheme of the present invention, the invention is described in detail below through specific examples:

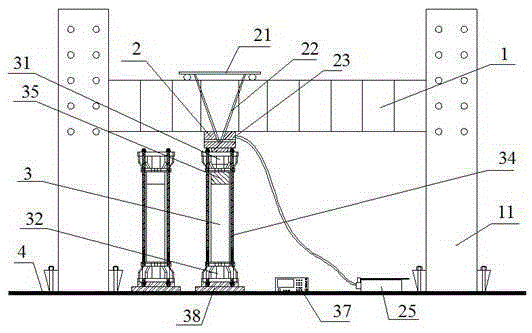

[0024] see Figure 1 to Figure 9 As shown, a self-balancing loading device for batch concrete filled steel tubes includes a reaction frame, a jack 2, an upper cover plate 31, a lower cover plate 32 and steel pipes 3 for pouring concrete;

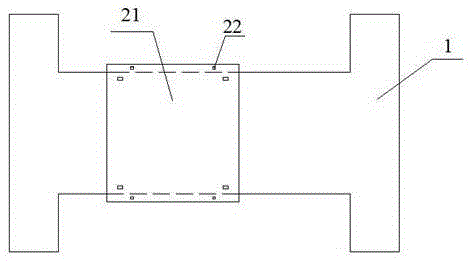

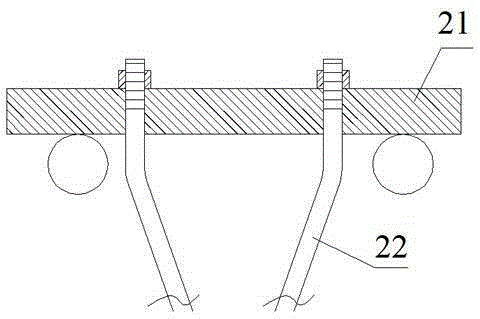

[0025] Described reaction force frame is made up of I-shaped reaction force frame crossbeam 1 and four reaction force frame pillars 11, and described four reaction force frame pillars 11 upper ends are connected with the upper and lower beams of I-shaped reaction force frame crossbeam 1 respectively. The ends are fixedly connected by anchor bolts, and the lower ends of the four reaction frame pillars 11 are fixedly connected with the hardened concrete ground 4 by anchor bolts. The reaction frame beam 1 is provided with a sliding trolley 21 that can slide along the beam. A jack 2 with a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com