Scanning device for steel rail bottom transverse cracks

A technology of transverse crack and scanning device, which is used in transportation and packaging, analysis of solids and railway car body parts using sonic/ultrasonic/infrasonic waves, etc. , the effect of high detection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

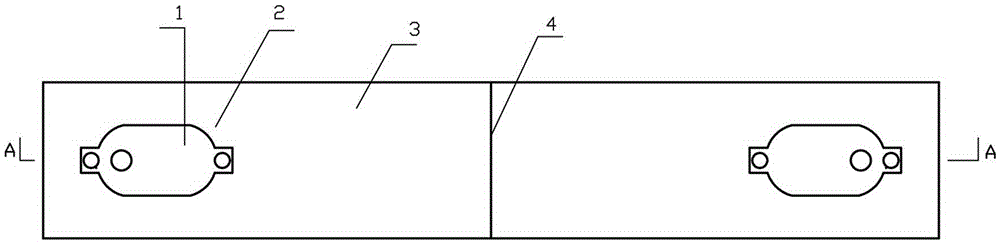

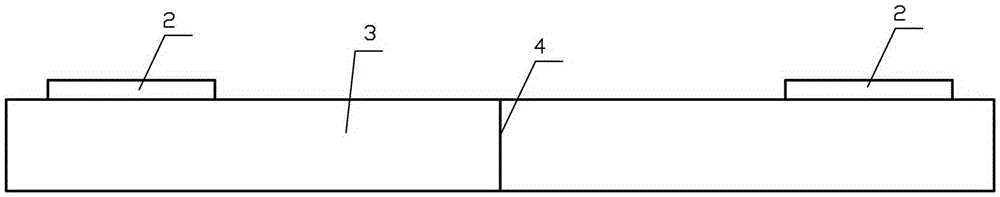

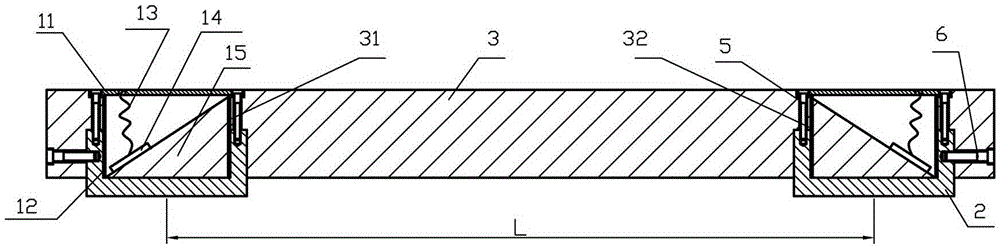

[0025] Such as figure 1 , figure 2 , image 3 As shown, a rail bottom transverse crack scanning device includes two ultrasonic probes, a probe protective film 2 and a scanning frame 3; the ultrasonic probe includes a box cover 11, a probe box 12, a piezoelectric wafer 14 and an organic glass inclined Wedge 15, plexiglass wedge 15 is installed in the probe box 12, the upper end of the probe box 12 is covered with a box cover 11, and the piezoelectric chip 14 (the piezoelectric chip 14 plays the role of sending and receiving ultrasonic waves) is installed in the plexiglass On the outward slope of the wedge block 15, the piezoelectric chip 14 is connected to the display screen of the flaw detector through the wire 13 (the wire 13 plays the role of transmitting signals and currents). There are a first installation hole 31 and a second installation hole 32 on it, and the two ultrasonic probes are respectively fixed in the first installation hole 31 and the second installation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com