Machining parameter optimization method based on general cutting energy consumption model

A technology of energy consumption model and processing parameters, applied in general control systems, simulators, instruments, etc., can solve the problem of high energy consumption of machine tools, and achieve the effect of improving processing efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

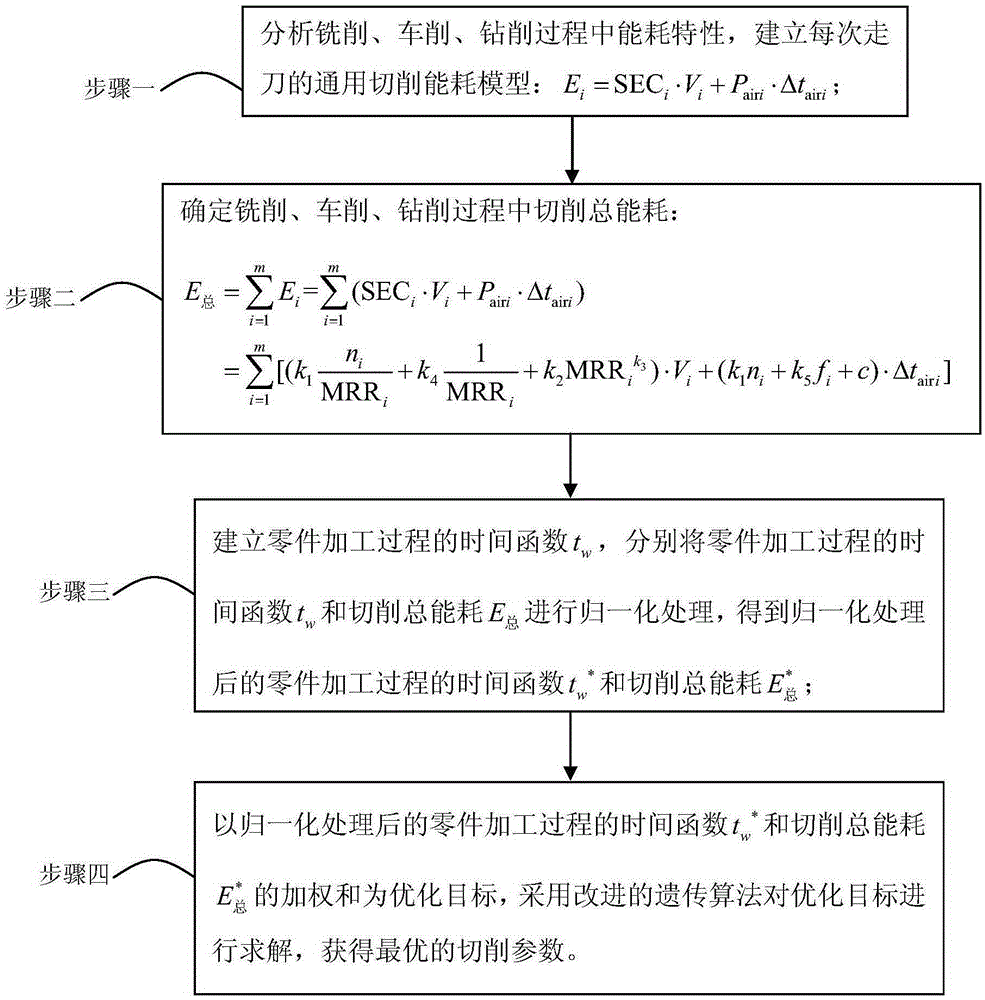

[0029] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0030] A processing parameter optimization method based on a general cutting energy consumption model, comprising the following steps:

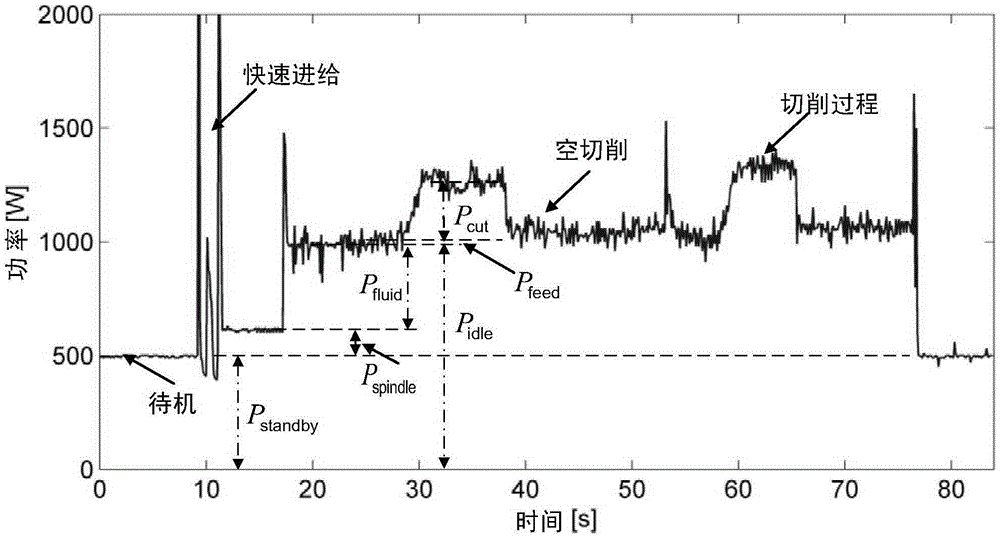

[0031] Step 1. Analyze the energy consumption characteristics during milling, turning, and drilling, and establish a general cutting energy consumption model for the above processing methods:

[0032] E=SEC·V+P air Δt air (1)

[0033] For each pass there is

[0034] E. i = SEC i ·V i +P airi ·△t airi (2)

[0035] Among them, E is cutting energy consumption; V is the volume of material removed; P air is the empty cutting power; △t air is the time of the empty cutting process; the subscript i is the serial number of the cutting tool, E i 、SEC i , V i ,P airi , Δt airi E, SEC, V, P corresponding to the i-th cutting tool pass respectively air , t air ;

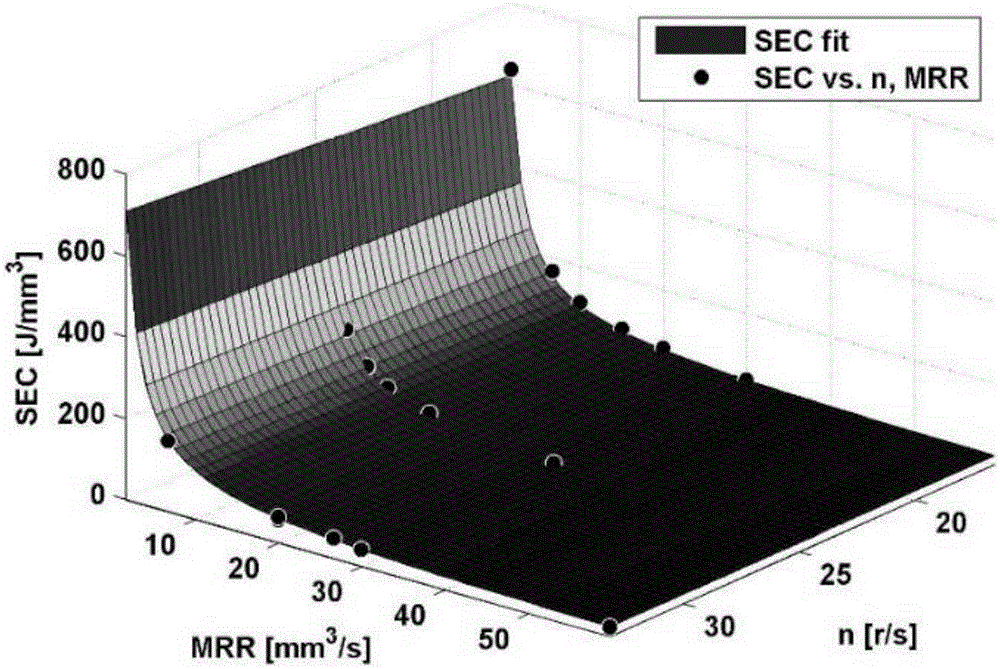

[0036] S E C = P ...

specific Embodiment approach 2

[0045] Specific embodiment two: the time function t of establishing the part processing process described in step 3 of this embodiment w as follows:

[0046] t w = π d V 1000 V c f t Za p a e + t c t πdVV c x - 1 a p y - 1 ...

specific Embodiment approach 3

[0049] Specific embodiment three: the time function t of the part machining process described in step 3 of this embodiment w The process of normalization processing is as follows:

[0050] t w * = t w ( V c , f t , a p , a e ) - t w min t w m a x - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com