Sodium cooled fast reactor power generation system using supercritical carbon dioxide working medium

A sodium-cooled fast reactor, carbon dioxide technology, applied in nuclear power generation, nuclear power plants, nuclear engineering and other directions, can solve the problems of weakening the economic level of sodium-cooled fast reactors, complex steam power plant systems, and reducing the competitiveness of sodium-cooled fast reactors , to avoid the problem of sodium-water reaction, improve economic competitiveness and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

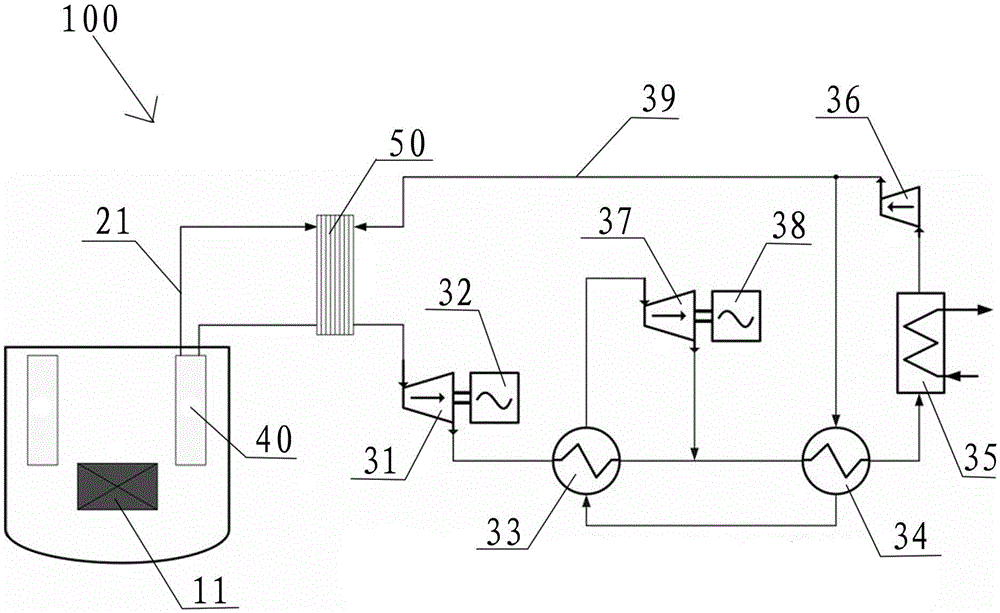

[0015] see figure 1 , the sodium-cooled fast reactor power generation system 100 shown in a preferred embodiment of the present invention includes a primary loop for providing heat source, a secondary loop for transferring heat, and a triple loop for converting thermal energy into electrical energy, the primary loop and the secondary loop Heat exchange is performed between the circuits through a first heat exchanger 40 , and heat exchange is performed between the second circuit and the third circuit through a second heat exchanger 50 .

[0016] The primary loop includes a first pipeline that communicates with the primary side of the first heat exchanger 40 and forms a closed circulation loop. The first pipeline is provided with a sodium-cooled fast reactor 11, which is used for the secondary loop and the secondary loop. The above three loops provide heat source. The coolant of the sodium-cooled fast reactor 11 is liquid sodium.

[0017] The secondary circuit absorbs heat fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com