Steam system energy expansion transformation optimization method, electronic equipment and storage medium

A technology of steam system and optimization method, which is applied in the direction of mechanical equipment, steam engine device, design optimization/simulation, etc., and can solve the problems of lack of global analysis and system optimization in steam system expansion and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

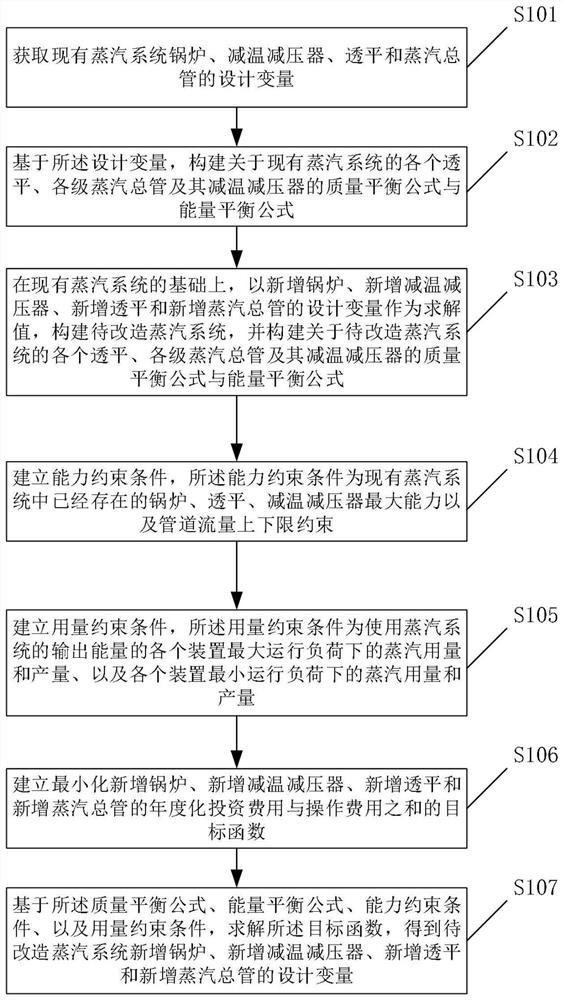

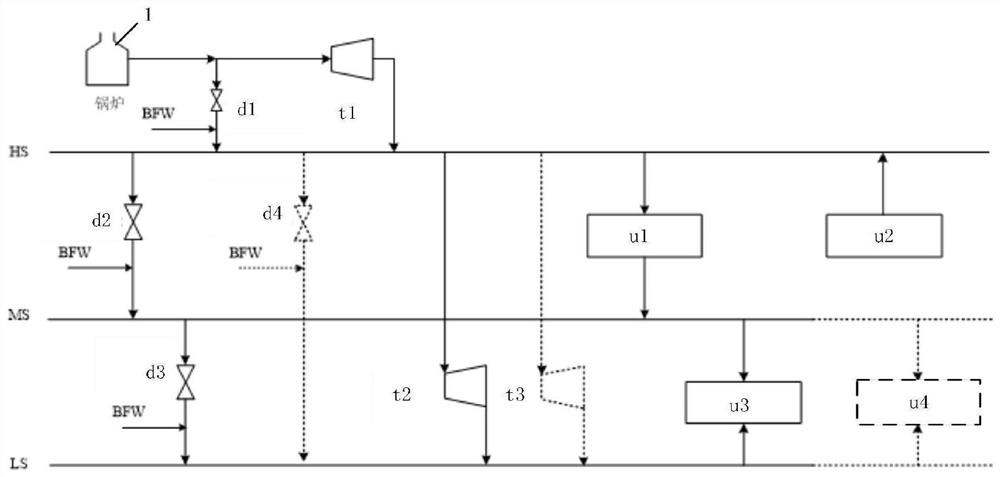

[0067] like figure 1 Shown is a working flow chart of a steam system capacity expansion transformation optimization method according to an embodiment of the present invention, including:

[0068] Step S101, obtaining the design variables of the existing steam system boiler, desuperheater, turbine and steam header;

[0069] Step S102, based on the design variables, construct mass balance formulas and energy balance formulas for each turbine, steam headers at all levels and their temperature and pressure reducers in the existing steam system;

[0070] Step S103, on the basis of the existing steam system, use the design variables of the newly-added boiler, newly-added desuperheater, newly-added turbine, and newly-added steam main pipe as the solution values to construct the steam system to be transformed, and construct the steam system to be transformed. Renovate the mass balance formula and energy balance formula of each turbine, steam header at all levels and its temperature...

Embodiment 2

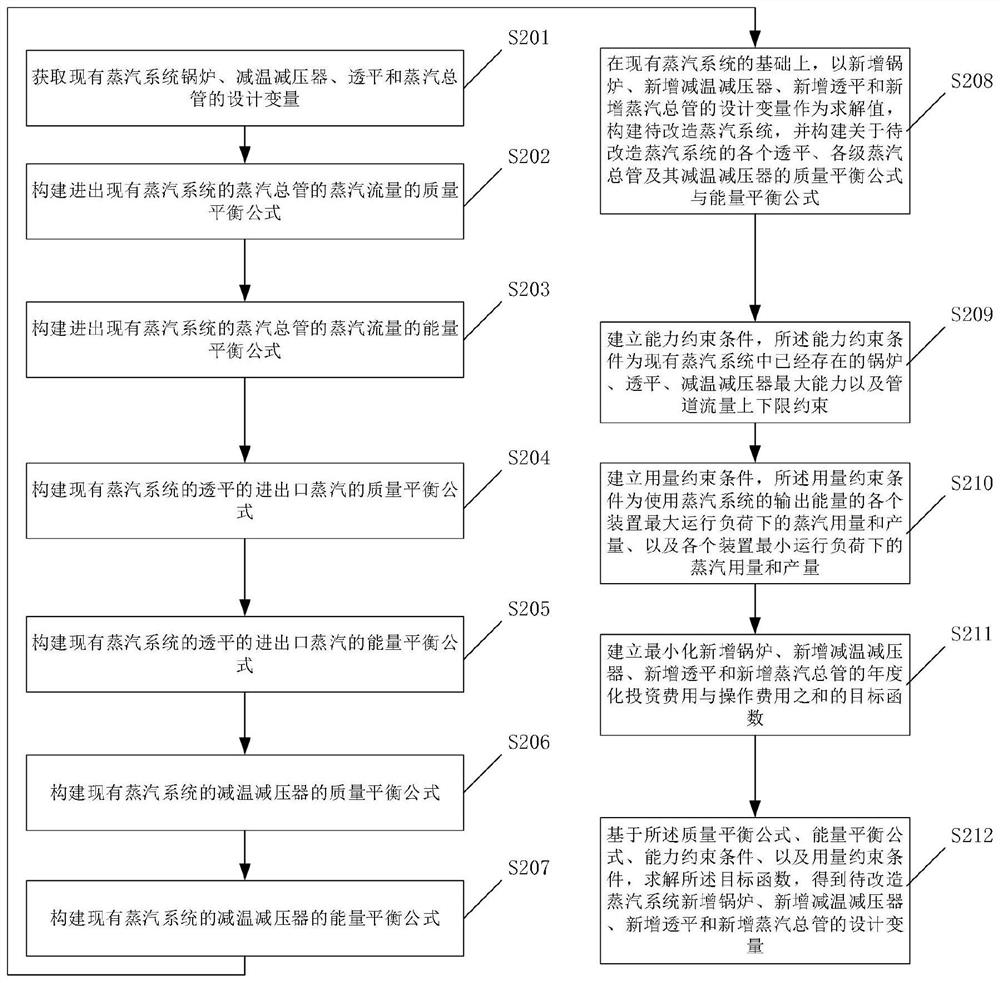

[0079] like figure 2 Shown is a working flow chart of a steam system capacity expansion transformation optimization method according to an embodiment of the present invention, including:

[0080] Step S201, obtaining the design variables of the existing steam system boiler, desuperheater, turbine and steam header;

[0081] Step S202, constructing the mass balance formula of the steam flow in and out of the steam main pipe of the existing steam system:

[0082]

[0083] Step S203, constructing the energy balance formula of the steam flow in and out of the steam main pipe of the existing steam system:

[0084]

[0085] In the formula, F represents the steam flow rate, h represents the specific enthalpy of the stream, the subscript b represents the bth boiler of the existing steam system, the subscript r represents the rth steam main pipe of the existing steam system, and the subscript t represents the existing steam The tth turbine of the system, the subscript d indicat...

Embodiment 3

[0207] like Figure 4 Shown is a schematic diagram of the hardware structure of the steam system capacity expansion transformation optimization electronic equipment of the present invention, including:

[0208] at least one processor 401; and,

[0209] A memory 402 communicatively connected to at least one processor 401; wherein,

[0210] The memory 402 stores instructions that can be executed by at least one of the processors 401, and the instructions are executed by at least one of the processors 401, so that at least one of the processors 401 can execute the aforementioned steam system Optimization method for capacity expansion and transformation.

[0211] Figure 4 A processor 401 is taken as an example.

[0212] The electronic device may further include: an input device 403 and a display device 404 .

[0213] The processor 401, the memory 402, the input device 403, and the display device 404 may be connected through a bus or in other ways, and the connection through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com