KOH-supported Xanthoceras sorbifolia husk active carbon catalyst and preparation method and application thereof

A fruit shell and activated carbon technology, which is applied in the field of catalyst and preparation of KOH supported by Wenguan fruit shell activated carbon, can solve the problems of difficult separation of catalyst and biodiesel, strict requirements on raw materials, and inability to recycle, etc., and achieves widening raw material sources and easy separation. , the effect of easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

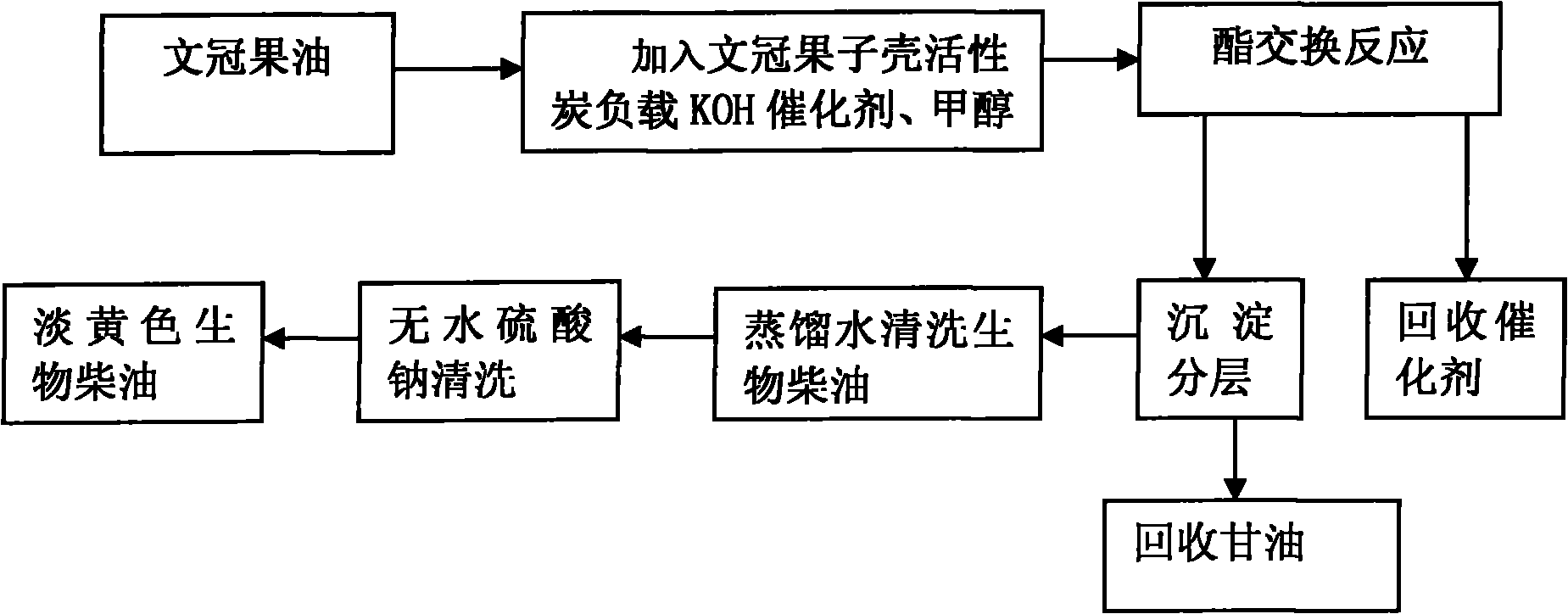

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of preparation method of the catalyzer of Radix radix radix radix shell activated carbon load KOH, it comprises the following steps successively, (1) Radix radix radix radiata active carbon pretreatment; (2) prepare the radix radix radix radix shell activated carbon load KOH catalyst; 3) Catalyst loaded with KOH on activated carbon of X. sorbifolia fruit shell was calcined at 300°C; (4) Finished product packaging; Among them,

[0032] (1) Pretreatment of X. radix radix radix activated carbon: Put the X. xanthus X. X. husk activated carbon in a drying oven and dry at 100°C for 2 hours to remove impurities and moisture on the surface of X. X. X. X. X. X. husk activated carbon;

[0033] (2) Preparation of X. radix radix radix shell activated carbon loaded KOH catalyst: take 500 grams of X. radix radix radiata shell activated carbon after pretreatment, add 55ml of 10% KOH solution, stir continuously for 1-2h, make it mix evenly, then, put Remove moistur...

Embodiment 2

[0042] Embodiment 2: a kind of preparation method of the catalyzer of Radix radix radix radix shell activated carbon load KOH, it comprises the following steps successively, (1) Radix radix radix radiata active carbon pretreatment; (2) prepare the radix radix radix radix shell activated carbon load KOH catalyst; 3) Catalyst loaded with KOH on activated carbon of X. radix radix radiata shell was calcined at 600°C; (4) Finished product packaging; Among them,

[0043] (1) Pretreatment of X. radix radix radix activated carbon: put the X. xanthii activated carbon in a drying oven at 200°C for 4 hours to remove impurities and moisture on the surface of the X. xanthus activated carbon;

[0044] (2) Preparation of X. radix radix radix shell activated carbon loaded KOH catalyst: Weigh 500 g of the pretreated X. radix radix radiata active carbon, add 125 ml of 40% KOH solution, stir continuously for 1-2 h to make it evenly mixed, and then put it into a dry Moisture was removed in the bo...

Embodiment 3

[0053] Embodiment 3: a kind of preparation method of the catalyzer of Radix radix radix radix shell active carbon load KOH, it comprises the following steps successively, (1) Radix radix radix radiata active carbon pretreatment; (2) prepares the radix radix radix shell activated carbon load KOH catalyst; 3) Catalyst loaded with KOH on activated carbon of X. sorbifolium fruit shell is calcined at 500°C; (4) Finished product packaging; Among them,

[0054] (1) Pretreatment of X. radix radix radix activated carbon: put the X. radix X. radicis activated carbon in a drying oven and dry at 150°C for 3 hours to remove impurities and moisture on the surface of X. radix X. radicis activated carbon;

[0055] (2) Preparation of X. radix radix radix shell activated carbon loaded KOH catalyst: Take 500 g of pretreated X. radix X. radicis activated carbon, add 214 ml of 30% KOH solution, stir continuously for 1-2 h to make it evenly mixed, and then put it in a dry Moisture was removed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com