Cable hole plugging device for power cabinet

A technology of blocking device and screen cabinet, which is applied in the substation/distribution device shell, substation/switch layout details, electrical components, etc. The effect of convenience, simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

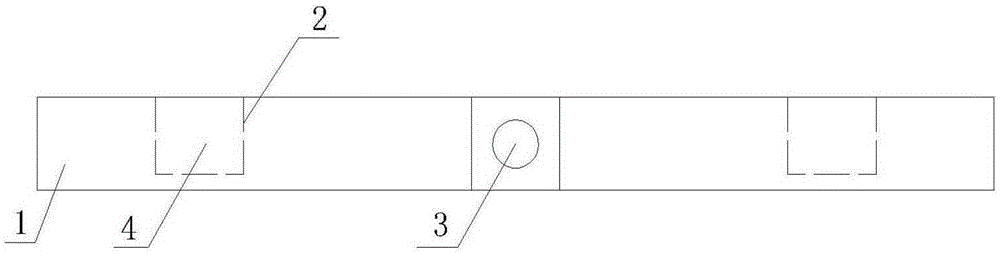

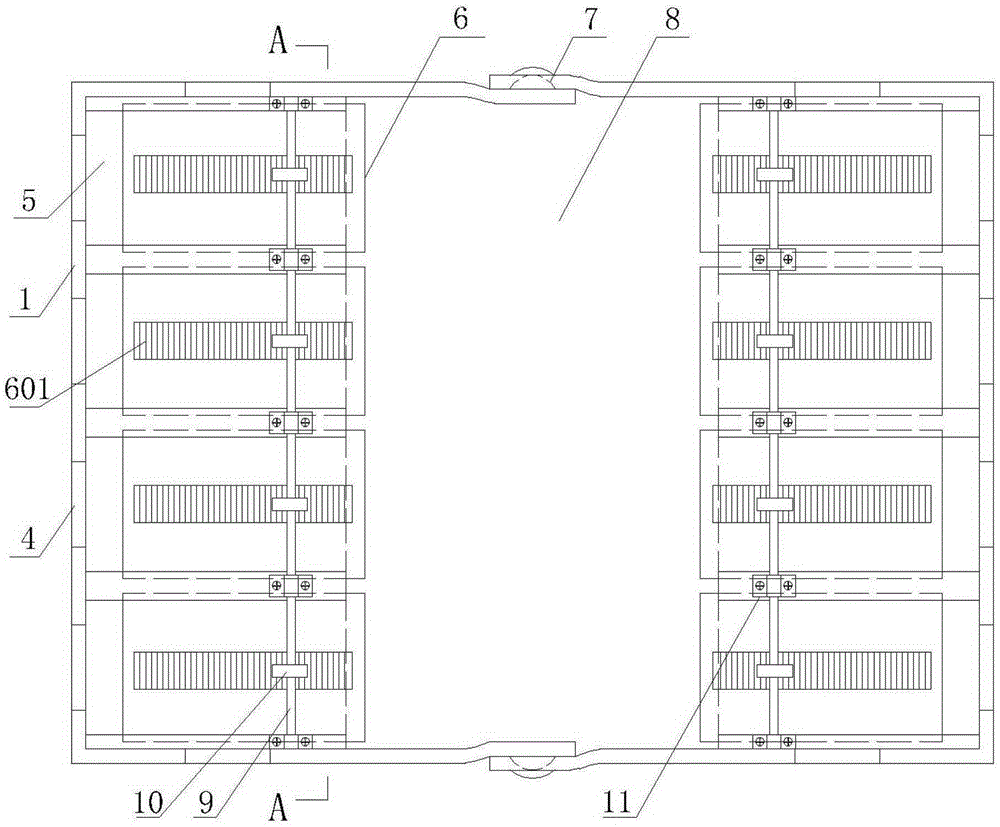

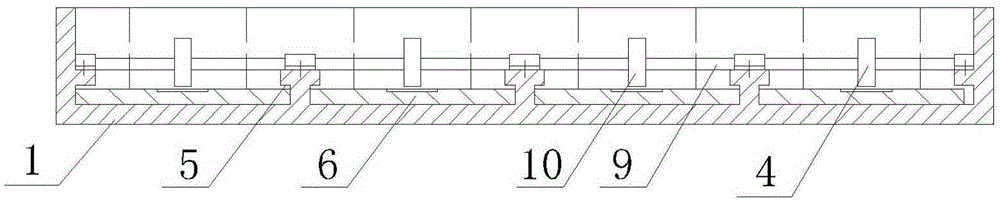

[0023] Such as Figure 1-Figure 3 As shown, the present invention relates to a cable hole plugging device for power screen cabinets. It has a grooved housing 1, and a threading hole 8 is provided in the middle of the bottom surface of the grooved housing 1. The inner bottom surface of the groove of 1 is positioned at threading hole 8 both sides and is symmetrically provided with multiple sets of slideways 5, and in each slideway 5, is respectively provided with slidable adjustment slide plate 6, and adjustment slide plate 6 cooperates with slideway 5 sliding gaps. The middle part of the upper surface of the adjustment slide plate 6 is provided with a rack-shaped locking tooth 601 along its longitudinal direction, and two rotating shafts 9 are symmetrically arranged on both sides in the groove of the grooved housing 1, and the rotating shafts 9 are fixed on the Inside the trough housing 1. Positioning cams 10 are sheathed on the rotating shaft 9 corresponding to the rack-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com