Centrifuge frequency-converting control circuit and control method thereof

A technology of frequency conversion control and control method, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of centrifuge vibration, large motor heating, large current, etc., to achieve strong overload capacity, less heat, and low starting current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

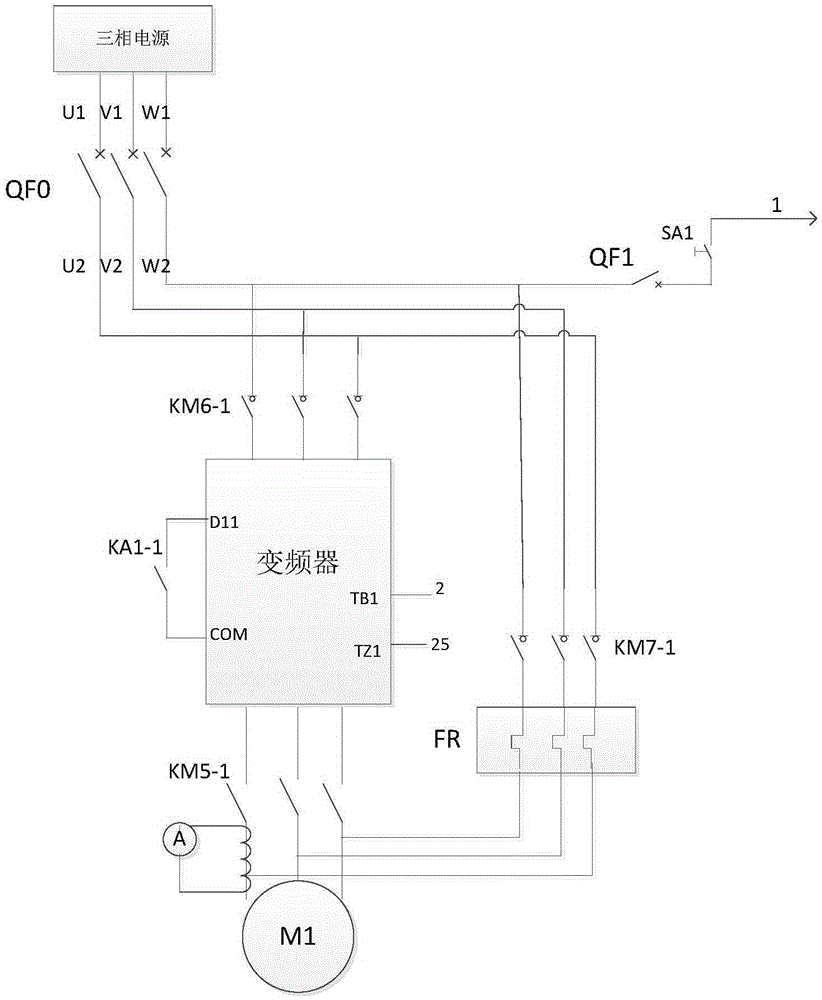

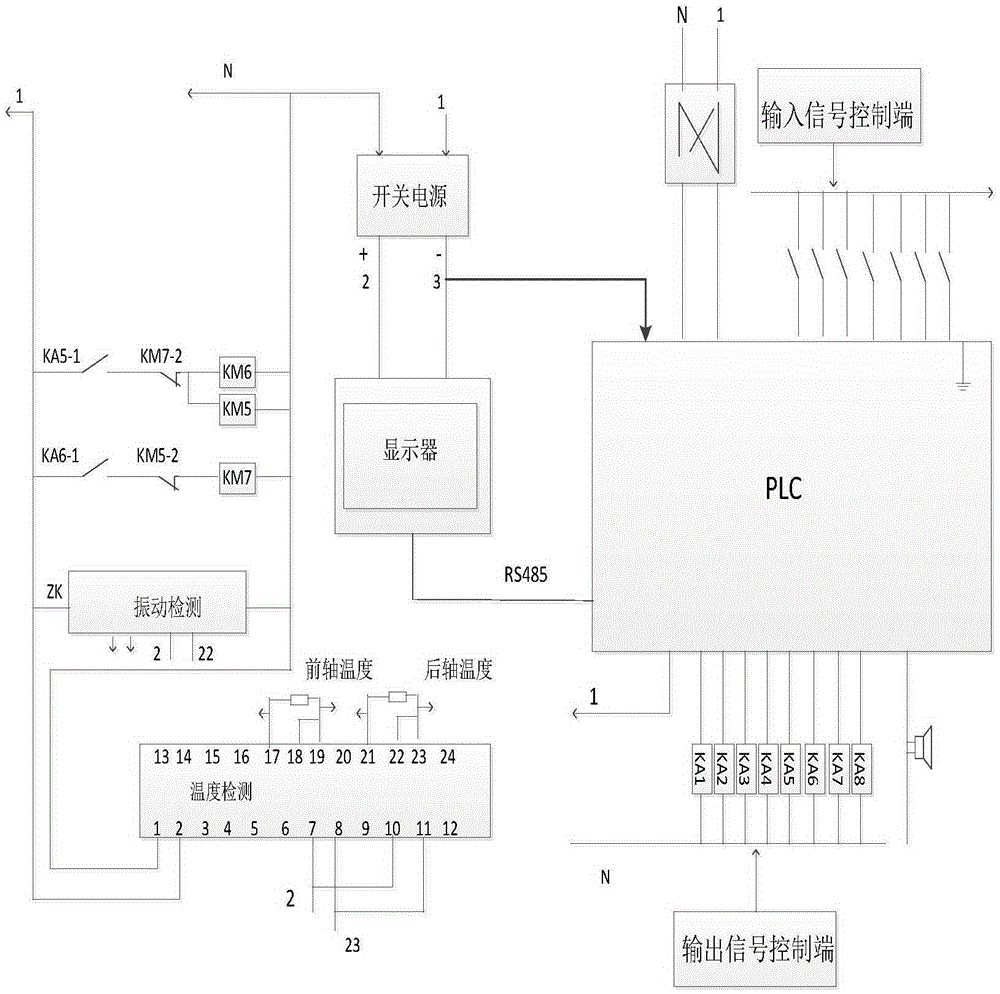

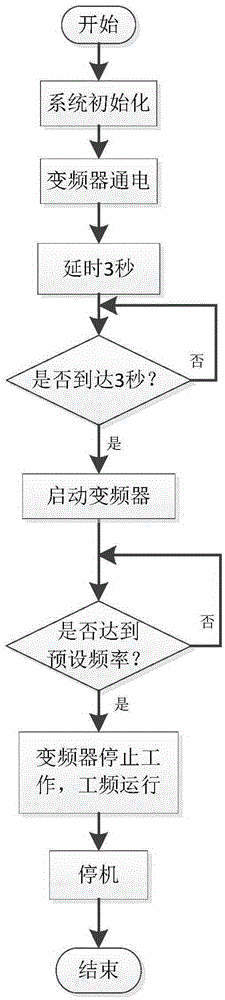

[0026] From figure 1 It can be seen that a centrifuge frequency conversion control circuit, the centrifuge is provided with a frequency conversion power supply circuit and a power frequency power supply circuit; a frequency converter is provided in the frequency conversion power supply circuit, and the power input end of the frequency converter passes through the normally open switch KM6- of the contactor KM6. 1 Connect the power frequency three-phase power supply, the power output terminal of the frequency converter supplies power to the centrifuge through the normally open switch KM5-1 of the contactor KM5, and the normally open switch KA1-1 of the relay KA1 is also connected to the frequency converter. To realize the start-up control of the frequency converter; the normally open switch KM7-1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com