Solid Moringa oleifera leaf drink

A technology of solid beverage and Moringa leaf, which is applied in food science, application, food ingredients, etc., can solve the problems of high equipment purchase cost and later maintenance cost, expenditure, convenience of taking, and low acceptance of the crowd, etc. Good, nutritious and healthy, and easy to drink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 solid drink of the present invention

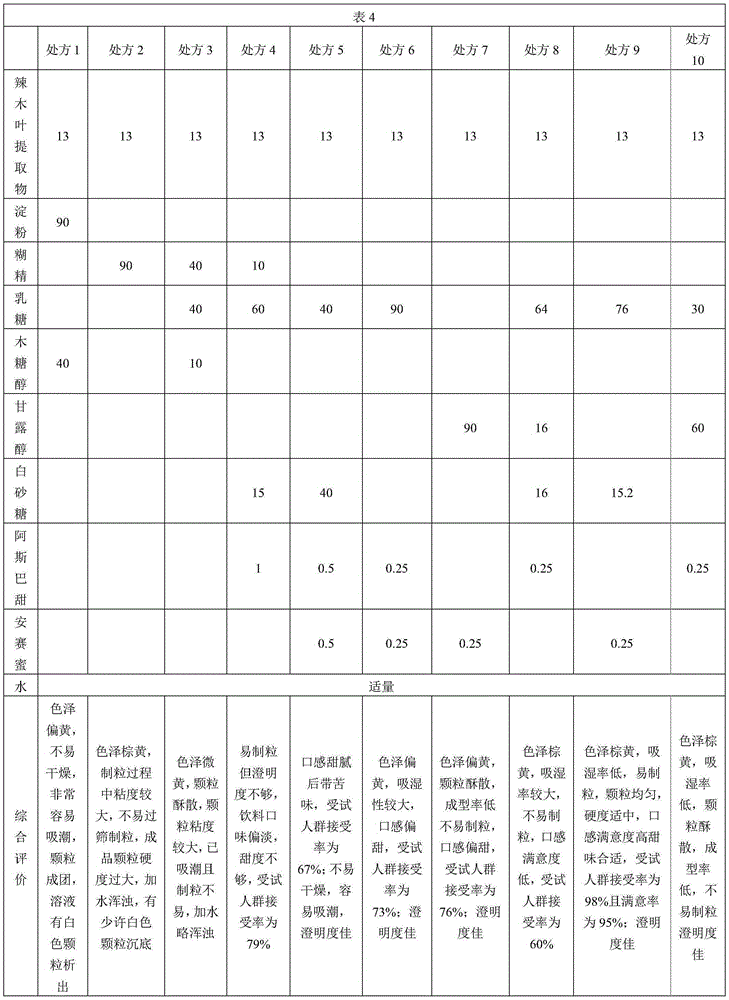

[0030] 1. Prescription

[0031] Moringa leaf water extract 130g lactose 76g white sugar 15.2g acesulfame honey 0.25g

[0032] 2. Preparation process

[0033] Take Moringa oleifera leaves, add 20 times of water to decoct twice, each time for 0.5 hours, filter through an 80-mesh sieve, concentrate under reduced pressure at 80 degrees to a relative density of 1.03 (measured at a temperature of 55°C), cool to room temperature, and centrifuge (5000r / min), the centrifugate is concentrated into a thick paste (the relative density of the thick paste measured at a temperature of 25°C is 1.37).

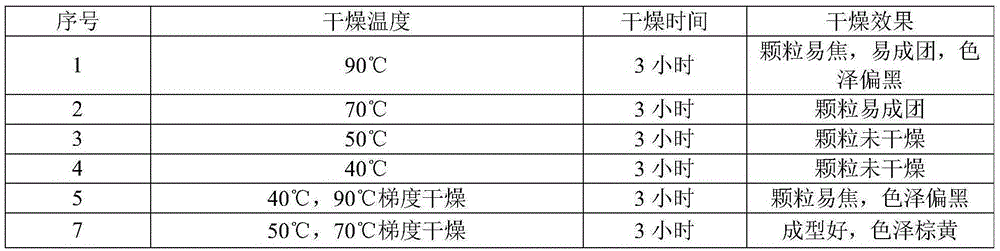

[0034] According to the prescription ratio, add lactose, white granulated sugar, and acesulfame potassium in the corresponding proportion, mix evenly, pass through a 24-mesh sieve, granulate, dry (gradient drying, 50°C for one hour, 70°C for two hours), granulate, and pack, that is, .

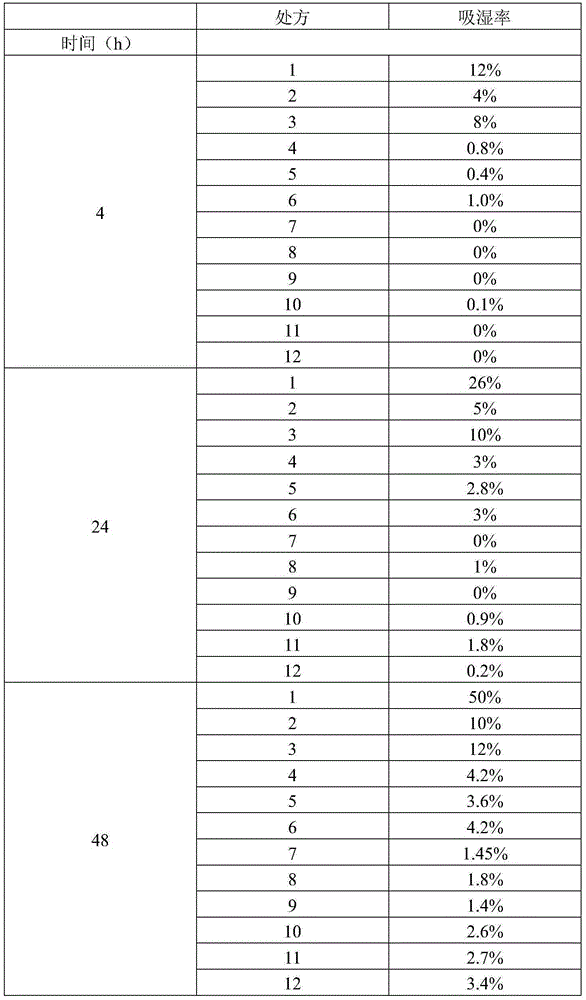

[0035] 1. Determination of...

Embodiment 2

[0053] Embodiment 2 The preparation of solid beverage of the present invention

[0054] 1. Prescription

[0055] Moringa leaf water extract 130g lactose 76g white sugar 15.2g acesulfame 0.20g

[0056] 2. Preparation process

[0057] Take Moringa oleifera leaves, add 20 times of water to decoct twice, each time for 0.5 hours, filter through an 80-mesh sieve, concentrate under reduced pressure at 80 degrees to a relative density of 1.03 (measured at a temperature of 55°C), cool to room temperature, and centrifuge (5000r / min), the centrifugate is concentrated into a thick paste (the relative density of the thick paste measured at a temperature of 25°C is 1.37).

[0058] According to the prescription ratio, add lactose, white granulated sugar, and acesulfame potassium in the corresponding proportion, mix evenly, pass through a 24-mesh sieve, granulate, dry (gradient drying, 50°C for one hour, 70°C for two hours), granulate, and pack, that is, .

Embodiment 3

[0059] Embodiment 3 The preparation of solid beverage of the present invention

[0060] 1. Prescription

[0061] Moringa leaf water extract 130g lactose 76g white sugar 15.2g acesulfame 0.30g

[0062] 2. Preparation process

[0063] Take Moringa oleifera leaves, add 20 times of water to decoct twice, each time for 0.5 hours, filter through an 80-mesh sieve, concentrate under reduced pressure at 80 degrees to a relative density of 1.03 (measured at a temperature of 55°C), cool to room temperature, and centrifuge (5000r / min), the centrifugate is concentrated into a thick paste (the relative density of the thick paste measured at a temperature of 25°C is 1.37).

[0064] According to the prescription ratio, add lactose, white granulated sugar, and acesulfame potassium in the corresponding proportion, mix evenly, pass through a 24-mesh sieve, granulate, dry (gradient drying, 50°C for one hour, 70°C for two hours), granulate, and pack, that is, .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com