Cloth cutting machine for shoemaking

A cloth-cutting machine and cloth-cutting technology, which is applied in the direction of shoe-making machinery, footwear, and applications, can solve the problems of knife die damage, fabric waste, and elongated shoe-making process production cycle, so as to save fabric and improve production. Efficiency, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Implementation column 1

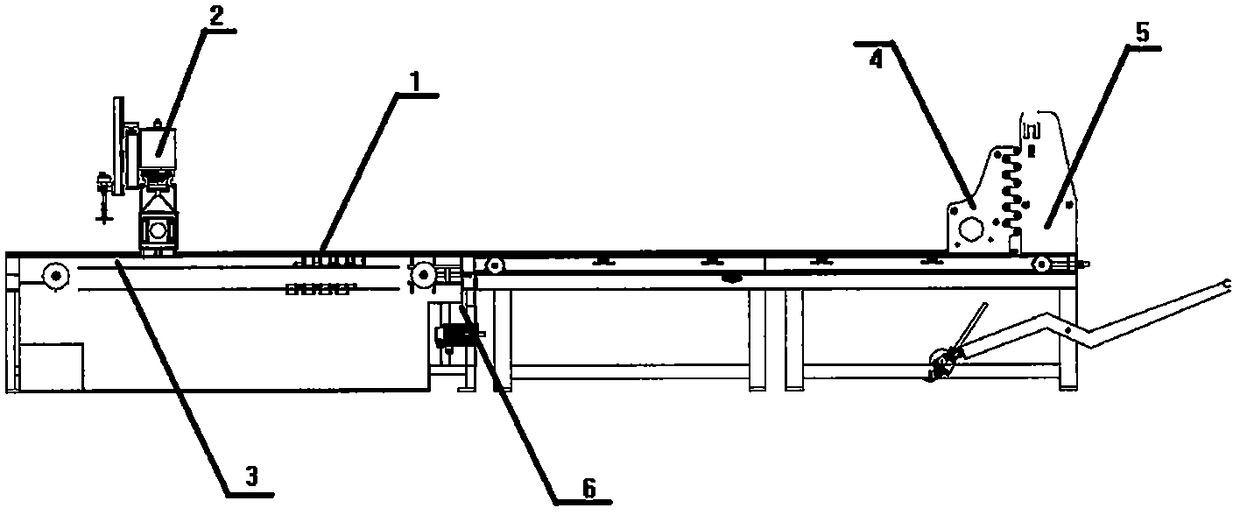

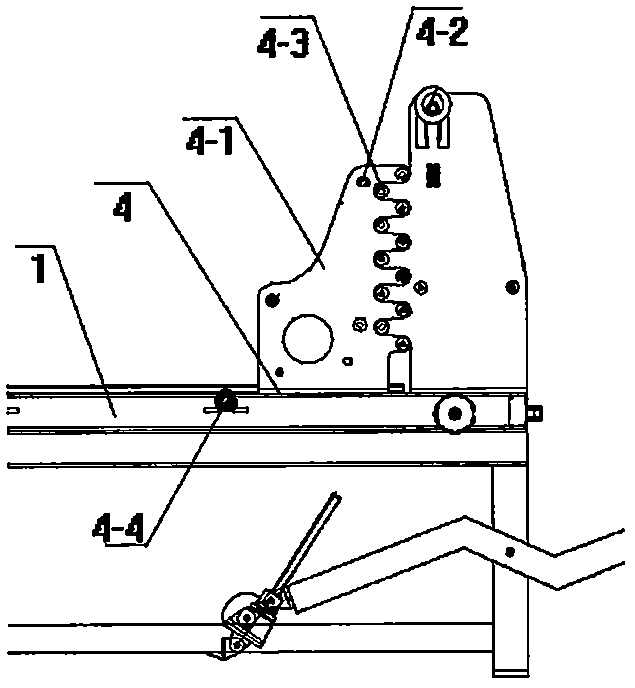

[0024] The cloth upper device 5 is arranged on the rear top of the frame 1, the cloth-folding and cloth-cutting conveying device 4 is arranged on the frame 1, the cloth-cutting supporting conveying platform 3 is arranged on the front part of the frame 1, and the first cloth-cutting device 2. Set above the cloth cutting support conveying platform 3;

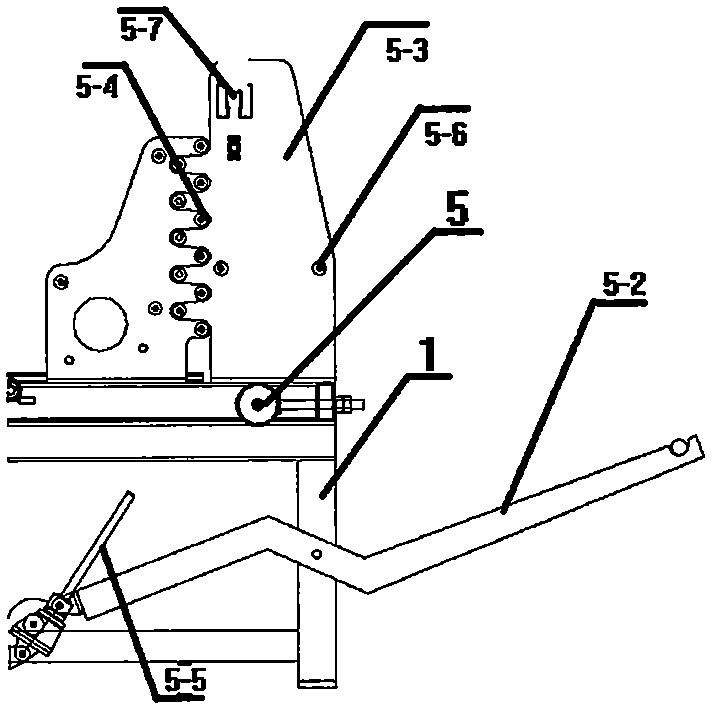

[0025] Described upper cloth device 5 is made up of frame 1, cloth rack 5-2, upper cloth fixing device 5-3, roller 5-4, stacking cloth adjustment lever 5-5, upper cloth clamping device 5-6, The cloth pressing device 5-7 is formed; wherein, the cloth stacking adjusting rod 5-5 is arranged under the frame 1, the cloth rack 5-2 is connected with the lower end of the cloth stacking adjusting rod 5-5, and the middle part of the cloth rack 5-2 is arranged on the machine frame. On the frame 1; the cloth folding device fixing device 5-3 is arranged on the frame 1; the upper cloth clamping device 5-6 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com