Stable casting grinding device

A casting, stable technology, applied in the direction of grinding/polishing safety devices, grinding machine parts, grinding machines, etc., to achieve the effect of reducing the amount of distortion, high speed, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

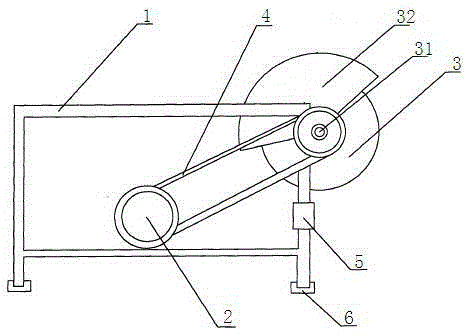

[0021] Such as figure 1 As shown, a stable casting grinding device includes a frame 1, a motor 2, and a cutting blade 3, the motor 2 is arranged on the frame 1, and is connected with the rotating shaft 31 of the cutting blade 3 by a chain 4; The middle part of the frame 1 is provided with a muffler 5 close to the cutting piece 3 , and the bottom of the frame 1 is provided with an anti-vibration mechanism 6 ; the cutting piece 3 is provided with a protective cover 32 .

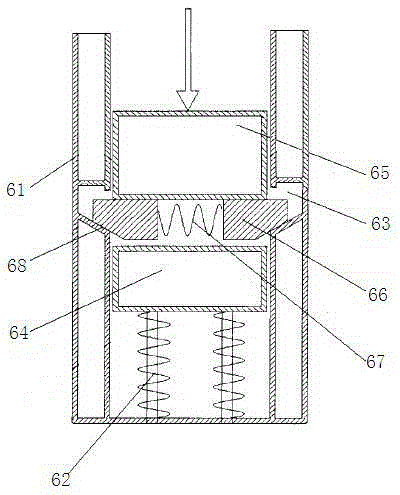

[0022] Such as figure 2 As shown, the anti-vibration mechanism 6 includes a hollow shell 61 and a first spring 62, and a transverse slot 63 is arranged inside the hollow shell 61; the bottom end of the first spring 62 is connected with the bottom of the inner wall of the hollow shell 61 , the top end of the first spring 62 is connected with a first slide block 64; the transverse buffer member is arranged in the transverse clamping groove 63, and the top surface of the transverse buffer member is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com