Split clamp and clamping boards

A split-type fixture technology, applied in workpiece clamping devices, metal processing equipment, clamping, etc., can solve the problems of reduced production efficiency, long replacement time, low safety factor, etc., achieve lightweight replacement, save replacement time, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

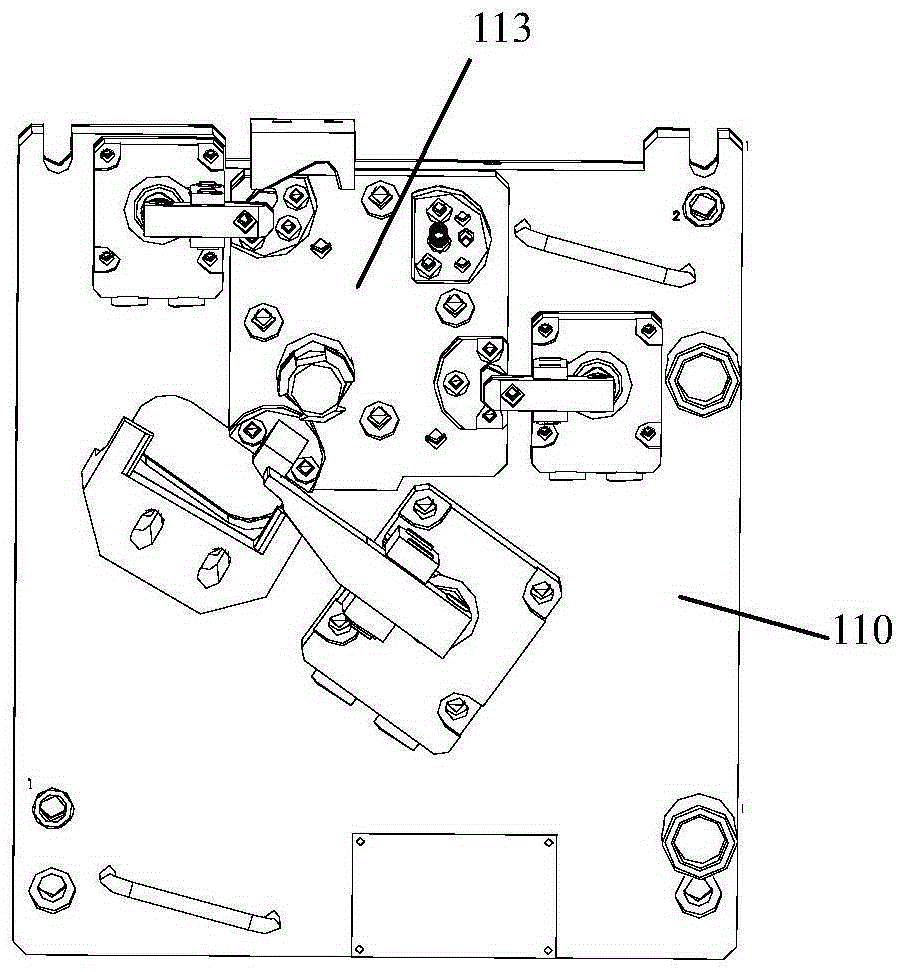

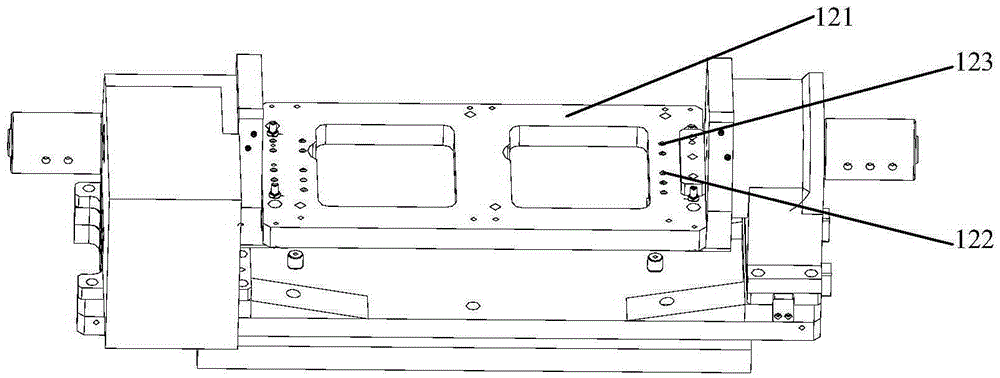

[0039] see Figure 1 to Figure 4 , the present invention discloses a split clamp, which is mainly assembled by a detachable clamping plate 110 and a base plate seat 120 .

[0040] in, figure 1 A schematic diagram of one embodiment of the removable clamping plate of the present invention is shown. The detachable clamping plate 110 is a substantially rectangular plate-like structure (other shapes are also possible, of course), on which at least a workpiece clamping piece 113 is disposed. Optionally, for the convenience of structural arrangement, the driving part of the workpiece clamping member 113 may also be arranged on the detachable clamping plate 110 for easy operation.

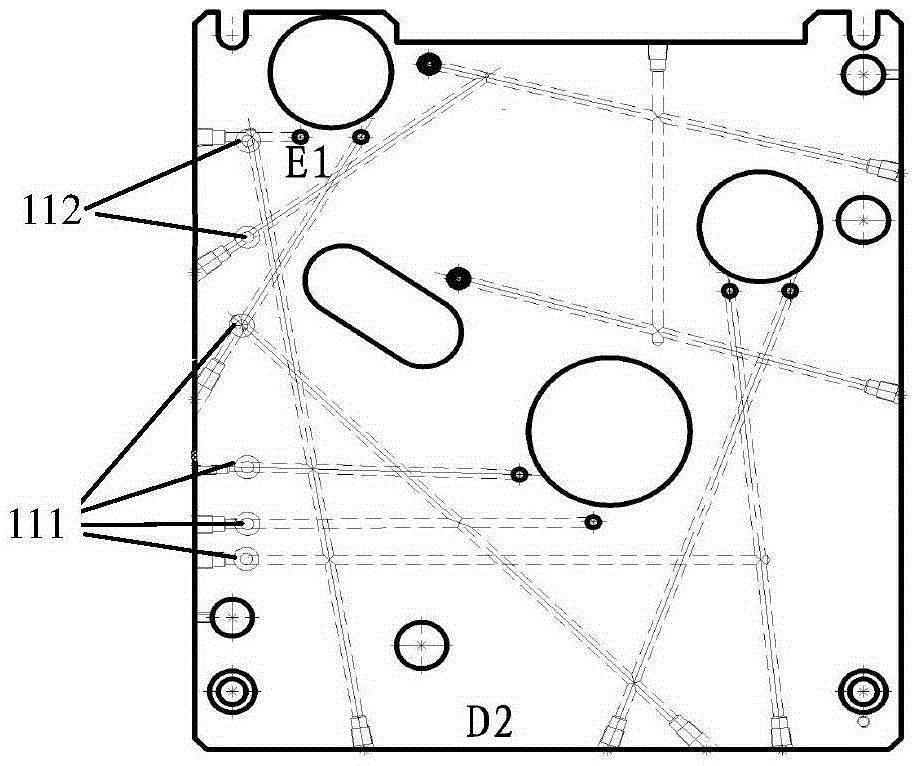

[0041] In addition, if figure 2 As shown, the detachable clamping plate 110 is also provided with a number of oil holes 111 and a number of air holes 112, which are respectively connected to a plurality of oil passages and air passages in the detachable clamping plate 110 for lubricating the device. A...

Embodiment 2

[0048] A split-type clamp includes: a detachable clamping mechanism, a carrying mechanism, and a positioning device. The detachable clamping mechanism is used for setting workpiece clamping parts; the bearing mechanism is provided with at least one mounting part, and the mounting part is used for carrying the detachable clamping mechanism. The positioning device is used for positioning the detachable clamping mechanism on the mounting part.

[0049] To sum up, the split fixture and clamping device proposed by the present invention can reduce the weight of the fixture and improve the convenience and safety of disassembly and assembly. When different workpieces need to be processed on the assembly line, only different types of detachable clamping plates need to be replaced, which makes the replacement of parts lightweight, reduces the risk of handling, saves replacement time, and indirectly improves processing efficiency. The versatility of the clamping device is also increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com