Mechanical arm of bottle blowing machine

A technology of manipulator and blow molding machine, applied in the field of blow molding machine manipulator, can solve the problems of loud noise, difficult assembly, long production cycle, etc., and achieve the effect of reducing noise and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

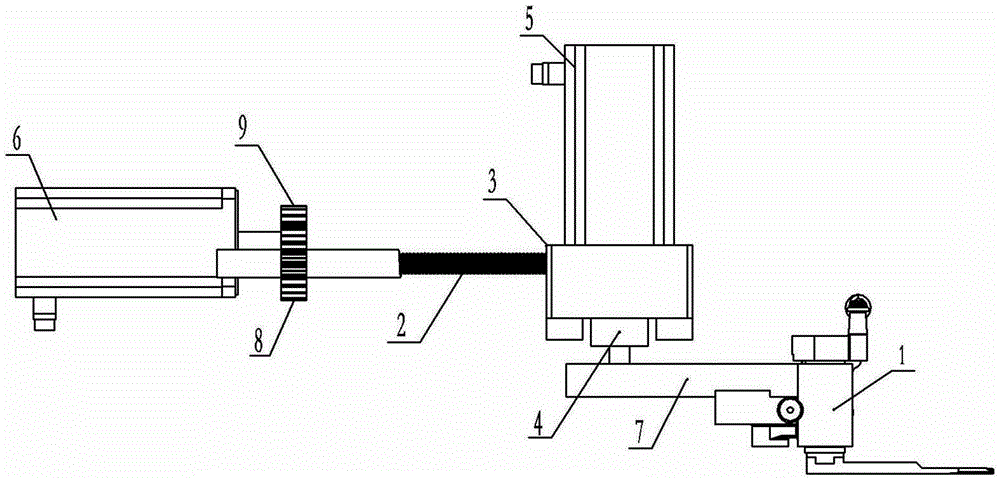

[0008] Such as figure 1 As shown, a bottle blowing machine manipulator includes a base 3 that can slide radially on the turntable, and a first drive motor 6 that can drive the base 3 to slide radially along the turntable on the turntable. The base 3 The rotating assembly 4 and the second drive motor 5 that can drive the rotating shaft of the rotating assembly 4 to rotate are installed on it, and the lower end of the rotating shaft protrudes downwards from the base 3 and is connected with the connecting rod 7 for installing the clamping portion. 5 can drive the connecting rod 7 to swing; it also includes a controller for controlling the start of the first drive motor 6 and the second drive motor 5, the controller inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap