Transverse stabilizing rod connecting device for automobile front axle

A technology of a stabilizer bar and a connecting device, which is applied in the directions of interconnection systems, vehicle components, transportation and packaging, etc., can solve the problems affecting the force and service life of the axle, increasing the production cost of the axle, and increasing the production process of the axle. , to achieve the effect of highlighting substantive features, simple structure and reducing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For ease of description, the present invention will be described in further detail below in conjunction with the accompanying drawings.

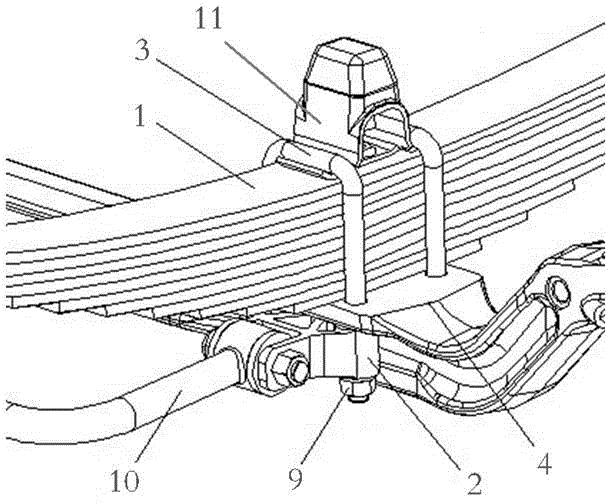

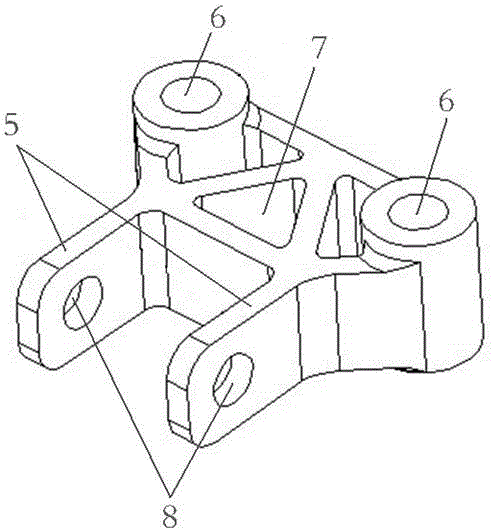

[0019] Such as figure 1 and figure 2 As shown, a kind of stabilizer bar connection device for automobile front axle of the present invention comprises U-bolt 3, leaf spring 1 and front axle 4 that are arranged successively from top to bottom, and front axle 4 is provided with for installing U The installation hole I of the type bolt 3, the U-shaped bolt 3 straddles the leaf spring 1; it also includes the stabilizer bar connecting plate body 2 for connecting the lateral stabilizer bar, and one end of the stabilizer bar connecting plate body 2 is provided with two mounting holes II6, the two ends of the U-bolt 3 pass through the installation hole I and the installation hole II6 in turn; the other end of the stabilizer bar connecting plate body 2 is provided with two parallel installation plates 5, and the two installation plates 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com