Novel welding rod packaging machine

A packaging machine and welding rod technology, applied in the field of machinery, can solve the problems of not being able to adapt to the production speed of the welding rod automatic production line, not meeting the needs of finished product packaging, and more labor, and achieve the effects of automatic operation, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

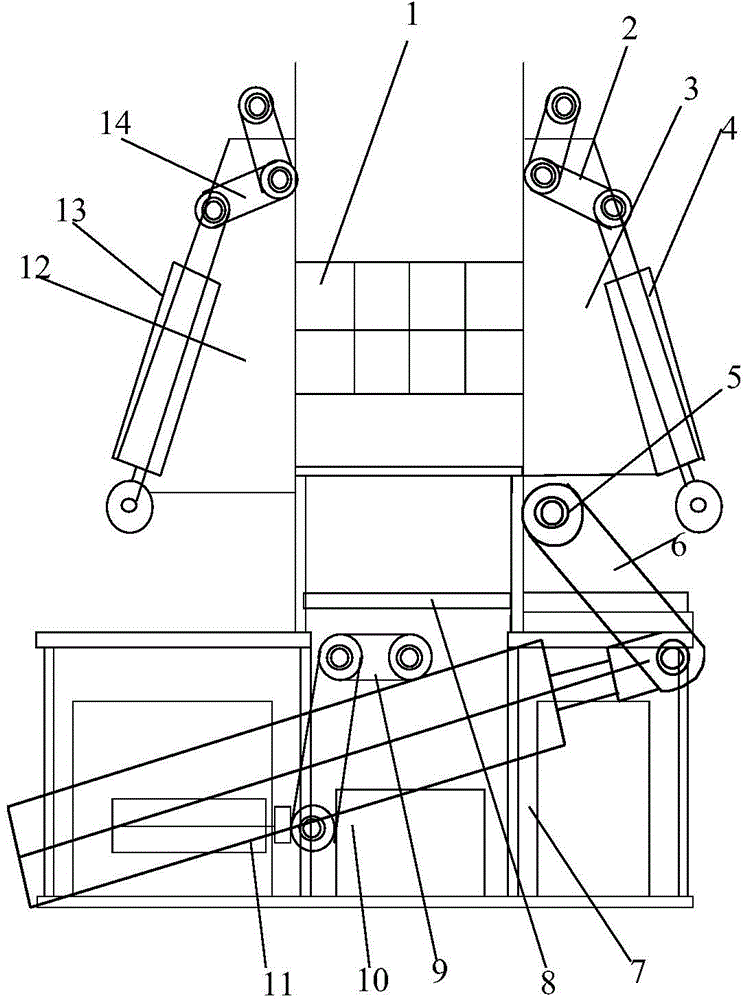

[0017] like figure 1 As shown, the present invention provides a novel welding rod packaging machine, comprising a support 7, a welding rod bracket 8, a fixed arm 12, an overturning arm 3, and a turning drive mechanism. The welding rod bracket 8 is installed in the middle of the support 7, and the welding rod Bracket 8 one side vertically installs fixed arm 12, installs flipping arm 3 on the support of electrode bracket 8 other sides, and flipping arm 3 lower ends are installed on the support 7 by swinging shaft rotation, and the swinging shaft of flipping arm 3 The turning drive mechanism is connected with the controller. The turning driving mechanism includes a cylinder 4 and a turning connecting rod 6. One end of the turning connecting rod 6 is hinged with the cylinder rod of the cylinder 4, and the other end is fixedly connected with the turning arm 3 and installed on the fixed arm 12. There is a rolling chain, and a pressing mechanism is installed on the turning arm 3; the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap