Foam warm mixing recycled asphalt mixture, preparation method and performance evaluation method

A technology of recycled asphalt and mixture, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of environmental pollution, discarding, not fully utilizing the warm mix asphalt technology for energy saving and emission reduction, etc. Reach the effect of reducing energy consumption and emission, reducing preparation cost and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

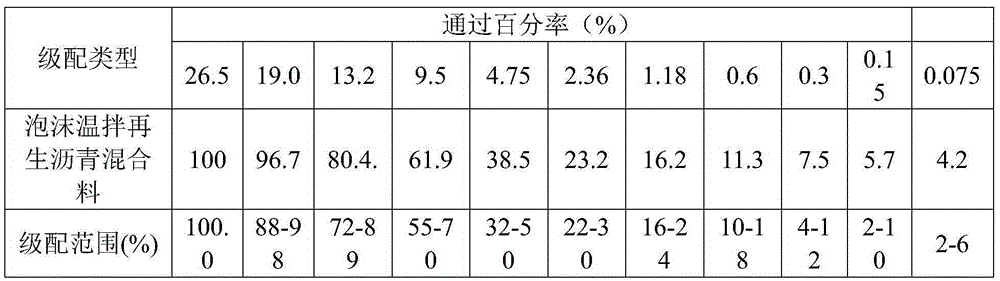

Embodiment 1

[0023] Before preparing the foam warm mix recycled asphalt mixture, first prepare the following materials:

[0024] 1. Recycled old materials: 80 parts of RAP1 material (rough milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 3.9%), 120 parts of RAP2 material (fine milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 4.6%);

[0025] 2. New pellets: 210 parts of 1# material, 270 parts of 2# material, 70 parts of 3# material, 240 parts of 4# material, 10 parts of mineral powder;

[0026] 3. Foam-modified asphalt: 42 parts of SBS modified asphalt, 1.2 parts of foaming water, foamed asphalt production equipment to ensure maximum air pressure of 1000kPa, maximum water pressure of 1000kPa, asphalt pressure of 1000kPa, suitable for asphalt temperature of 140-200℃, should be used in a certain amount of water Under the condition of large quantity, the foamed asphalt can be produced continuously, and the quality of...

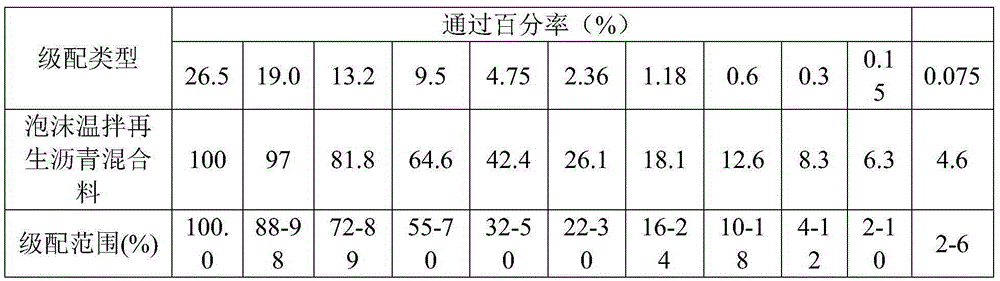

Embodiment 2

[0035] Before preparing the foam warm mix recycled asphalt mixture, first prepare the following materials:

[0036] 1. Recycled old materials: 80 parts of RAP1 material (rough milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 3.9%), 120 parts of RAP2 material (fine milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 4.6%);

[0037] 2. New pellets: 190 parts of 1# material, 255 parts of 2# material, 70 parts of 3# material, 270 parts of 4# material, 10 parts of mineral powder;

[0038] 3. Foam modified asphalt: 46 parts of SBS modified asphalt, 1.4 parts of foaming water, foamed asphalt production equipment to ensure maximum air pressure of 1000kPa, maximum water pressure of 1000kPa, asphalt pressure of 1000kPa, suitable for asphalt temperature of 140 ~ 200 ℃, should be used in a certain amount of water Under the condition of large quantity, the foamed asphalt can be produced continuously, and the quality...

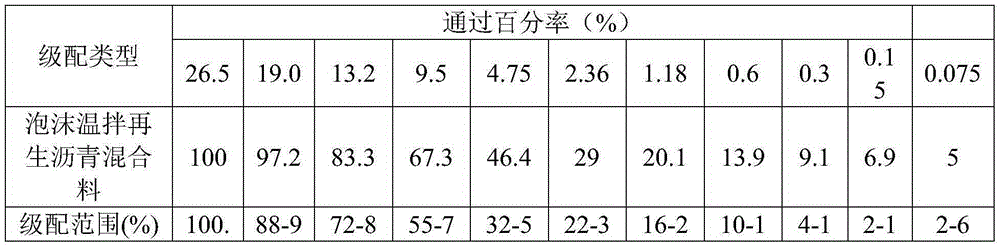

Embodiment 3

[0047] Before preparing the foam warm mix recycled asphalt mixture, first prepare the following materials:

[0048] 1. Recycled old materials: 80 parts of RAP1 material (rough milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 3.9%), 120 parts of RAP2 material (fine milling material for the lower layer of asphalt pavement, the ratio of asphalt to about 4.6%);

[0049] 2. New pellets: 175 parts of 1# material, 240 parts of 2# material, 70 parts of 3# material, 300 parts of 4# material, 10 parts of mineral powder;

[0050] 3. Foam modified asphalt: 50 parts of SBS modified asphalt, 1.5 parts of foaming water, foamed asphalt production equipment to ensure maximum air pressure 1000kPa, maximum water pressure 1000kPa, asphalt pressure 1000kPa, suitable for asphalt temperature 140 ~ 200 ℃, should be used in a certain amount of water Under the condition of large quantity, the foamed asphalt can be produced continuously, and the quality of the foamed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com