Large-sized blast furnace tap-hole clay

A technology for taphole and blast furnace, applied in the field of large-scale blast furnace taphole and preparation, can solve the problems of difficulty in production planning, affecting the stable tapping of the tap hole, and changing the hole diameter of the tap hole, so as to improve the instability of tap water and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

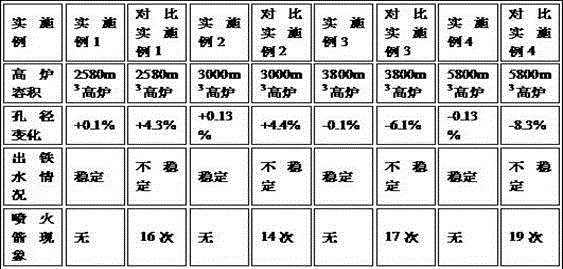

Embodiment 1

[0011] Embodiment 1: a kind of be used for 2580m3 large-scale blast furnace clay, it is characterized in that described large-scale blast furnace clay is made up of the following components by weight: 3-0mm ferrochrome spinel: 20 parts; 1-0mm corundum: 8 Parts; 1-0mm sillimanite: 15 parts; 0.5-0mm magnesia iron oxide: 15 parts; partial clay powder: 9 parts; cobalt aluminum oxide powder: 3 parts, cutting powder: 5 parts; graphite powder: 14 parts, composite carbon 10 parts of powder, medium temperature asphalt powder: 1 part; the preparation method of gun clay: put the above raw materials into the mixer and pre-mix for 15 minutes; prepare 13 parts of modified tar, first add 85% of the total amount of modified tar, Wet milling for 35 minutes; add the remaining 15% modified tar, and then wet milling for 15 minutes; slice through a mud slicer, and then form the mud by extrusion, cut into sections and cool to room temperature. The temperature of the mud in this step is set to The t...

Embodiment 2

[0012] Embodiment 2: a kind of be used for 3000m Large-scale blast furnace clay, it is characterized in that described large-scale blast furnace clay is made up of the following components by weight: 3-0mm ferrochrome spinel: 19 parts; 1-0mm corundum: 7 Parts; 1-0mm sillimanite: 14 parts; 0.5-0mm magnesia iron oxide: 15 parts; partial clay powder: 10 parts; cobalt aluminum oxide powder: 5 parts, cutting powder: 5 parts; graphite powder: 18 parts, composite carbon 6 parts of powder, medium temperature asphalt powder: 1 part. The preparation method of gun mud: Put all the raw materials into the mixer and pre-mix for 15 minutes; prepare 14 parts of modified tar, first add 85% of the total amount of modified tar, wet mill for 35 minutes; add the remaining 15% Modified tar, then wet milled for 15 minutes; sliced by a mud slicer, and then passed through a mud extruder, extruded to form, cut into sections and cooled to room temperature, and the extruded temperature in this step was...

Embodiment 3

[0013] Embodiment 3: a kind of be used for 3800m Large blast furnace clay, it is characterized in that described large blast furnace clay is made up of the following components by weight: 3-0mm ferrochrome spinel: 20 parts; 1-0mm corundum: 6 Parts; 1-0mm sillimanite: 14 parts; 0.5-0mm magnesia iron oxide: 13 parts; partial clay powder: 10 parts; cobalt aluminum oxide powder: 5 parts, cutting powder: 5 parts; graphite powder: 20 parts, composite carbon 6 parts of powder, medium temperature asphalt powder: 1 part. The preparation method of gun mud: put all the raw materials into the mixer and pre-mix for 15 minutes; prepare 15 parts of modified tar, first add 85% of the total amount of modified tar, and wet mill for 35 minutes; add the remaining 15% to modify tar, and then wet milled for 15 minutes; sliced by a gun mud slicer, and then passed through a mud extruder, extruded into shape, cut into sections and cooled to room temperature, and the extruded temperature in this step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com