Steel pipe pile internally provided with multiple arc-shaped stiffening ribs and construction method of steel pipe pile

A technology of stiffeners and steel pipe piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting the economics of engineering projects, increase construction and other costs, and increase processing difficulty, and achieve transportation and construction Low cost, superior mechanical performance, beneficial to design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

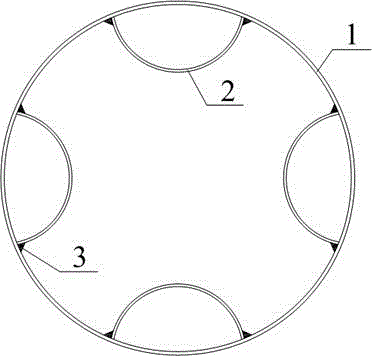

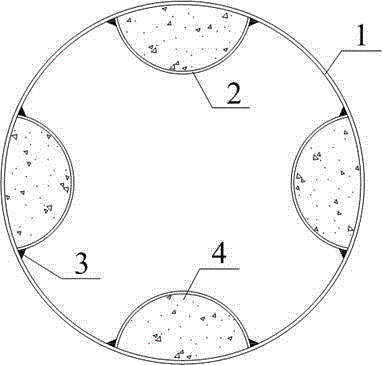

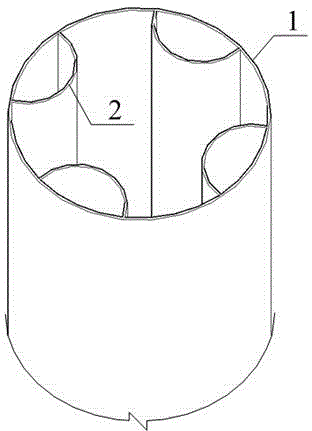

[0018] Such as Figure 1-Figure 4 As shown, the present invention is composed of a steel pipe 1 and a stiffening rib 2; the stiffening rib 2 is evenly arranged on the inner wall of the steel pipe 1, and the stiffening rib 2 is set in a full-length or partial way. The number of stiffeners 2 is 4 or more, and the shape of the stiffeners 2 is arc or other curved forms.

[0019] Both sides of the stiffener 2 are vertically welded on the inner wall 1 of the steel pipe 1 by fillet welds 3 or other methods; a pouring area is formed between the stiffener 2 and the inner wall of the steel pipe 1; the pouring area can be poured or not Pouring concrete 4.

[0020] Construction method of the present invention is:

[0021] a. The steel pipe 1 is rolled into shape in a steel structure processing plant and welded in sections to form a whole;

[0022] b. The stiffener 2 is vertically welded on the inner wall of the steel pipe 1 by fillet weld 3 or other methods, and other auxiliary structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com