Power transmission tower main material joint strength determination method

A power transmission tower, connection strength technology, applied to towers, building types, buildings, etc., can solve the problems of not considering the connection structure strength, not considering the extrusion effect of bolt connection on components, not considering the weakening of stress diffusion, etc., to achieve accurate and practical Stress situation, convenient tower calculation, simple and clear calculation formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

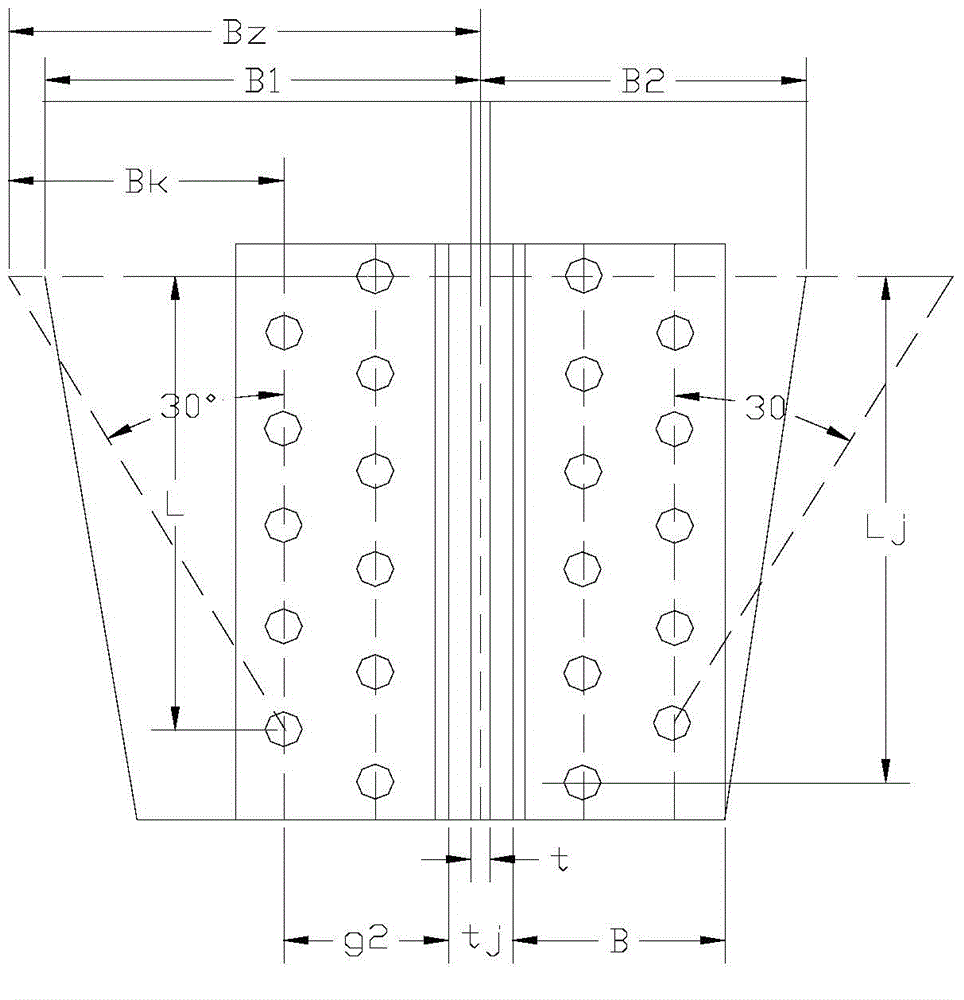

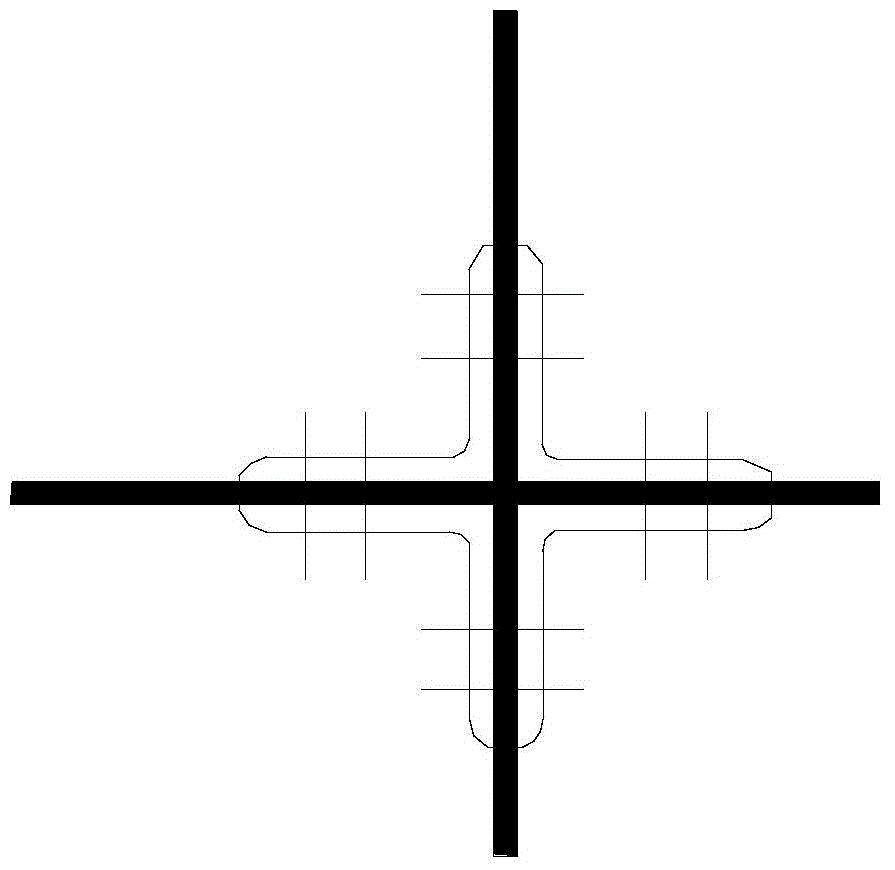

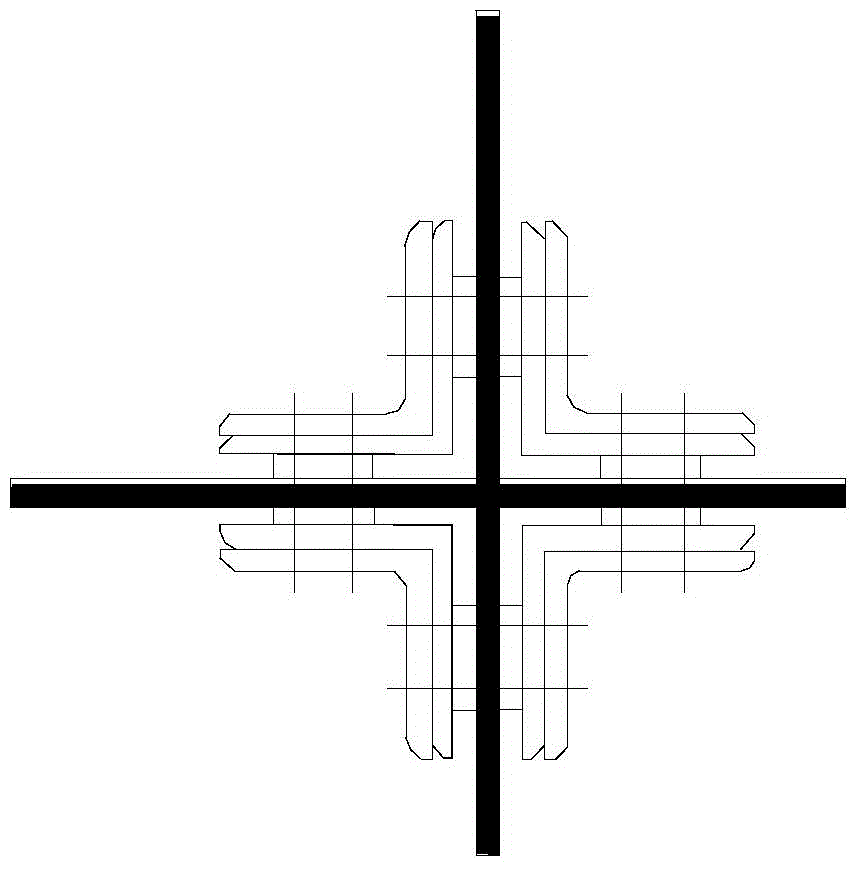

[0061] like Figure 1-8 As shown, the method for determining the connection strength of the main material of the transmission tower of this example is connected with bolts and connecting plates between the main materials; the method includes the following steps:

[0062] (1) determine the reduction factor of the main material;

[0063] (2) Determine the single-sided shear bearing capacity and single-sided extrusion bearing capacity of a single bolt;

[0064] (3) Determine the effective width of the connecting plate, the net area of the connecting plate, the net area of the inner cladding steel and the net area of the outer cladding steel;

[0065] (4) determine the joint strength of the main material;

[0066] (5) Determine the main material connection form.

[0067] The reduction factor in the step (1) is determined by the length of the connecting section of the main material, and the length is determined by the following formula:

[0068] Lj=(m / s-1)d1\(m / s-0.5)d1(1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com