Cold energy and waste heat comprehensive utilization system for liquefied natural gas (LNG) transport ship

A transport ship, cold energy technology, applied in waste heat treatment, lighting and heating equipment, steam application and other directions, can solve the problems of consuming heat sources, wasting LNG cold energy, etc., to save electricity, ensure reliability, and save operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

[0025] In view of the fact that currently about 70% of the LNG carriers in the world use steam power devices to propel the ships forward, ships with such power devices are the objects of invention and design for further description.

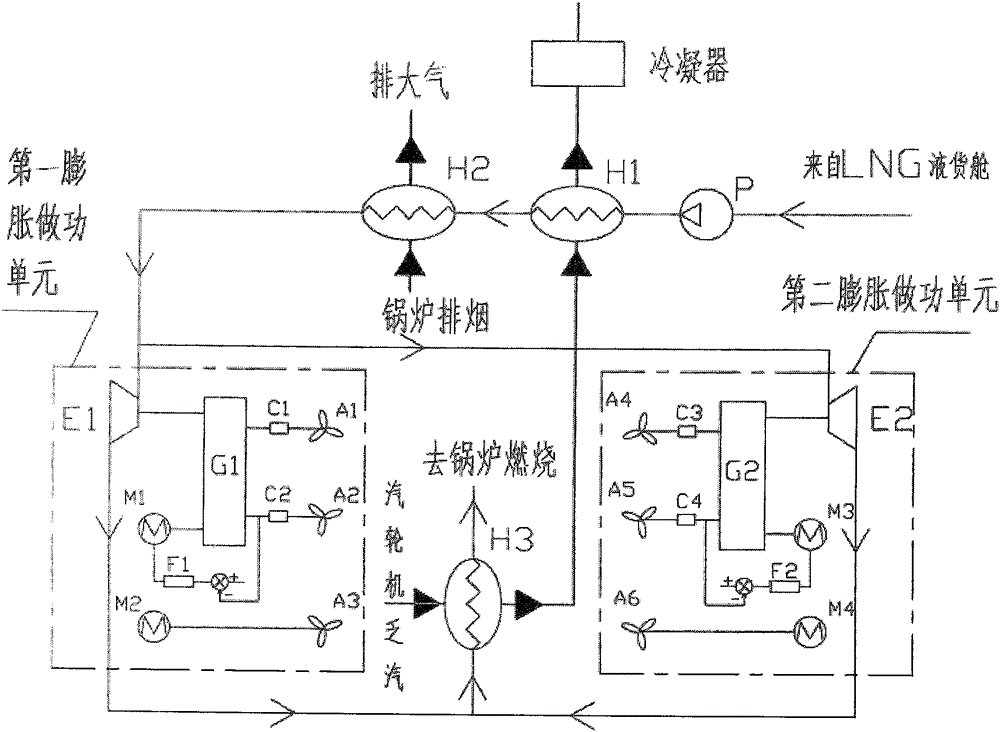

[0026] Such as figure 1 As shown, the comprehensive utilization system for cold energy and waste heat of an LNG carrier provided by the embodiment of the present invention includes a high-pressure pump P, a first heat exchanger H1, a second heat exchanger H2, a third heat exchanger H3, and a second heat exchanger. An expansion work unit and a second expansion work unit. The first heat exchanger H1 and the second heat exchanger H2 are sequentially connected to the outlet pipeline of the high-pressure pump P, and the first expansion work unit and the second expansion work un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com