A variable frequency fuel injector for an engine

A fuel injector and engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor atomization effect of fuel injectors, achieve good gasoline atomization effect, improve fuel atomization effect, increase Effects of Molecular Collision Chances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

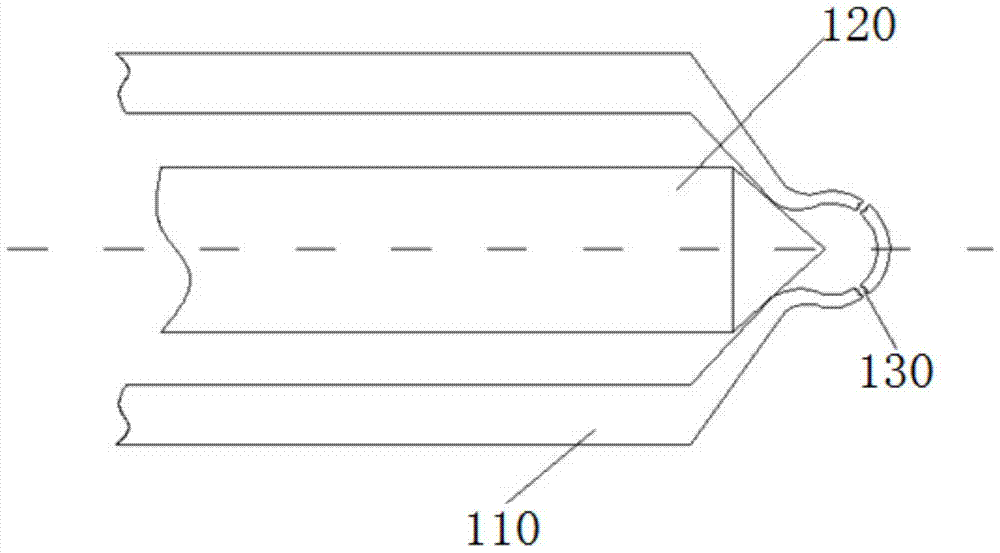

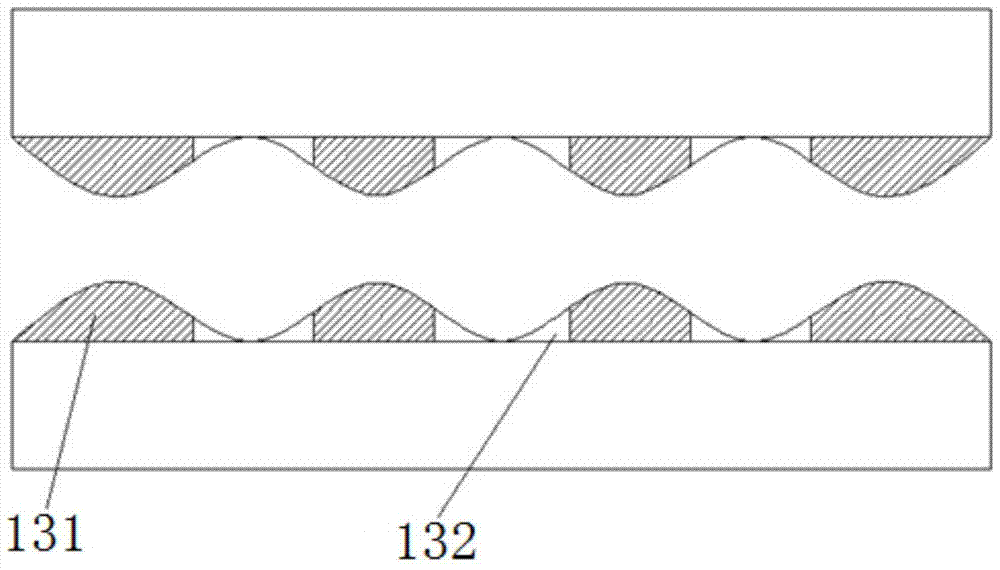

[0020] like figure 1 As shown, the present invention provides a variable frequency fuel injector for an engine, which includes a pump body 110 and a valve core 120 . Wherein the pump body 110 is set in a hollow shape, so as to form an oil liquid circulation channel inside it. The front end of the fluid circulation channel gradually shrinks along the direction of fluid circulation, forming a conical shape. An oil injection hole 130 is arranged at the front end of the pump body 110 , so that oil is sprayed out from the oil injection hole 130 . The valve core 120 is set in the hollow part of the pump body 110. The front end of the valve core 120 is set in a conical shape. The conical shape of the front end of the valve core 120 can cooperate with the conical shape of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com