Hot water apparatus and failure notification method for hot water apparatus

A hot water device and notification technology are applied in the field of detecting the blockage of the water circuit in the hot water device, and can solve the problems of low heating capacity and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

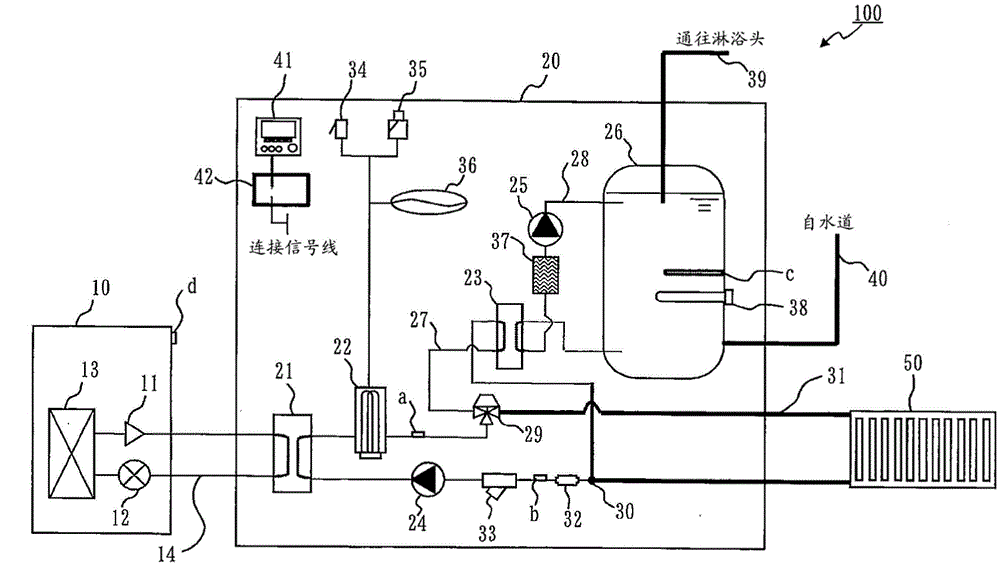

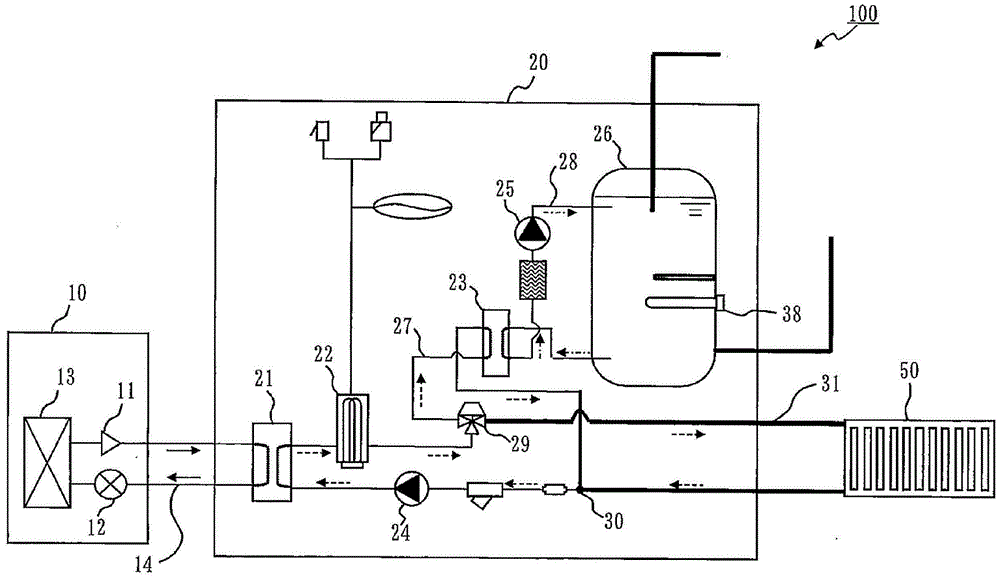

[0024] figure 1 It is a configuration diagram of the hot water device 100 according to Embodiment 1.

[0025] The hot water device 100 includes a heat pump device 10 (an example of a heat source device), a water heater 20 , and a heating device 50 .

[0026] The heat pump device 10 includes a compressor 11 , an expansion valve 12 , and a heat exchanger 13 .

[0027] The water heater 20 includes a heat exchanger 21, a heater 22, a heat exchanger 23, a pump 24, a pump 25, a tank 26, and the like.

[0028] The compressor 11 , the heat exchanger 21 , the expansion valve 12 , and the heat exchanger 13 are sequentially connected by pipes to constitute a refrigerant circuit 14 in which a refrigerant circulates.

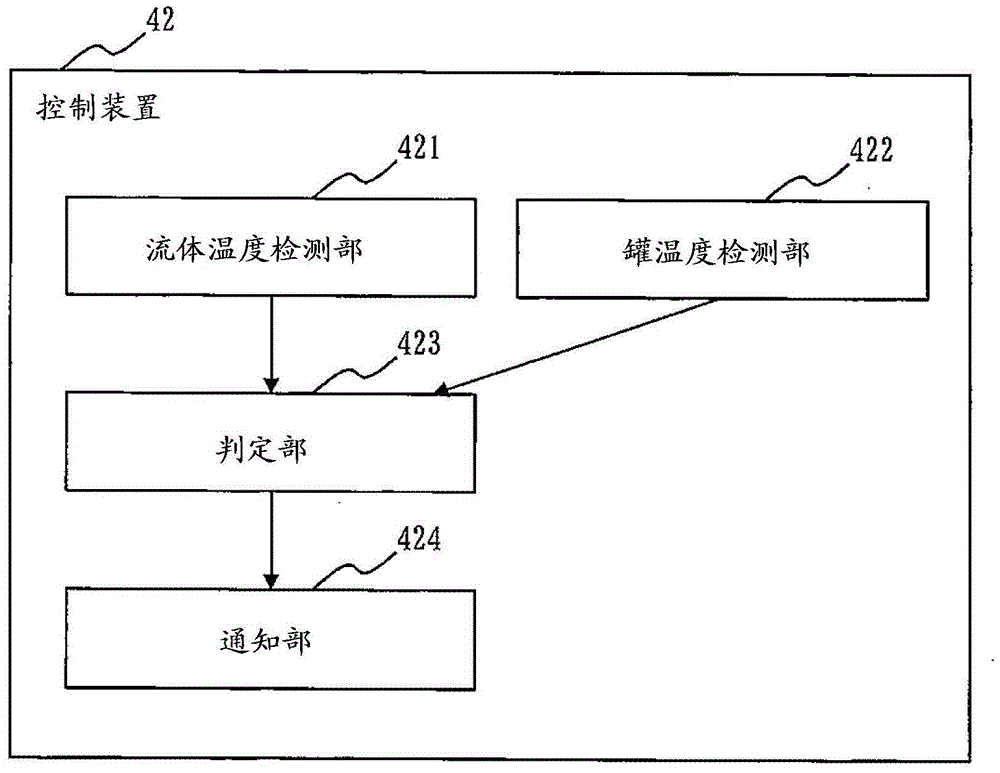

[0029] The heat exchanger 21 , the heater 22 , the heat exchanger 23 , and the pump 24 are sequentially connected by pipes to constitute a primary water circuit 27 (an example of a fluid circuit) for supplying and circulating water. Moreover, the heat exchanger 23, the pu...

Embodiment approach 2

[0076] In Embodiment 2, the control when the secondary water circuit 28 is clogged will be described.

[0077] In Embodiment 2, the description of the same parts as Embodiment 1 is omitted, and the parts different from Embodiment 1 will be described.

[0078] In Embodiment 1, when it is determined that the inflow temperature is not less than the first threshold and the tank temperature is not more than the second threshold, the user is notified that the secondary water circuit 28 is clogged. However, even if the clogging of the secondary water circuit 28 is notified, since the scale trapping device 37 and the heat exchanger 23 cannot be replaced immediately, there is a possibility that the hot water device 100 will be operated in a clogged state during this period of time. continue to operate.

[0079] Therefore, in Embodiment 2, when it is determined that the inflow temperature is equal to or greater than the first threshold and the tank temperature is equal to or less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com