Liquid crystal screen and gate COF structure assembly and liquid crystal display device

A technology of liquid crystal display devices and structural components, which is applied in the field of liquid crystal screen-gate COF structural components and liquid crystal display devices, and can solve the problem that it is difficult to realize the ultra-narrow bezel display design, and it is impossible to realize the ultra-thin and ultra-narrow bezel design of the liquid crystal display device at the same time , limited gate COF structure storage design and other issues, to achieve the effect of reducing bad stress, compact structure design, reducing thickness and frame length limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

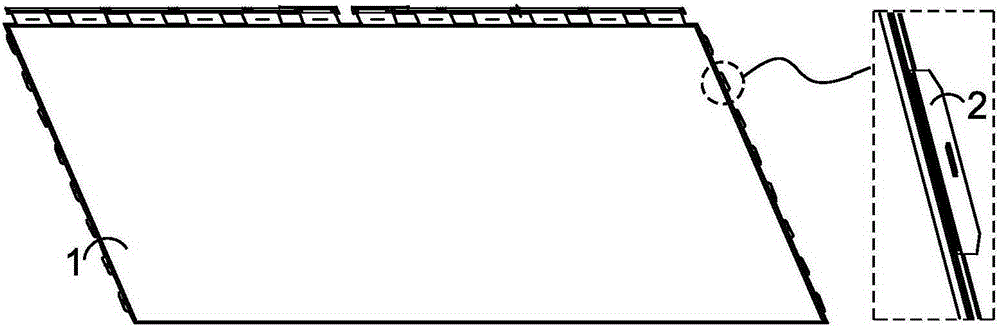

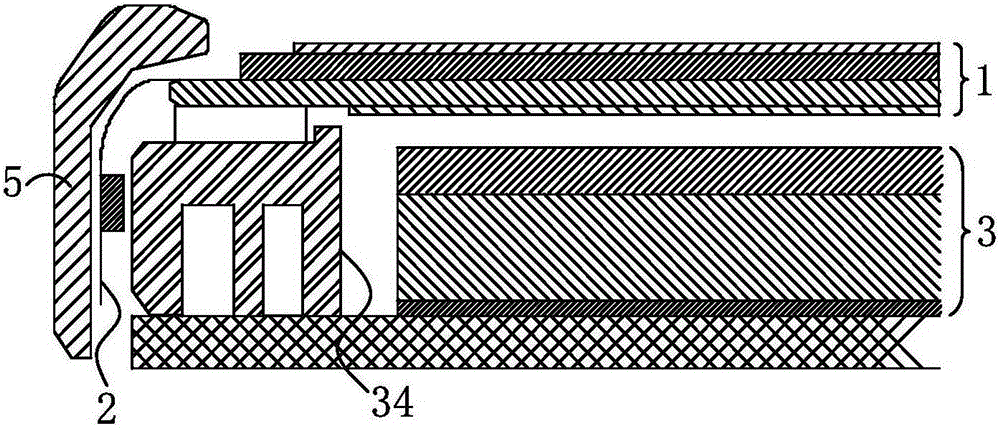

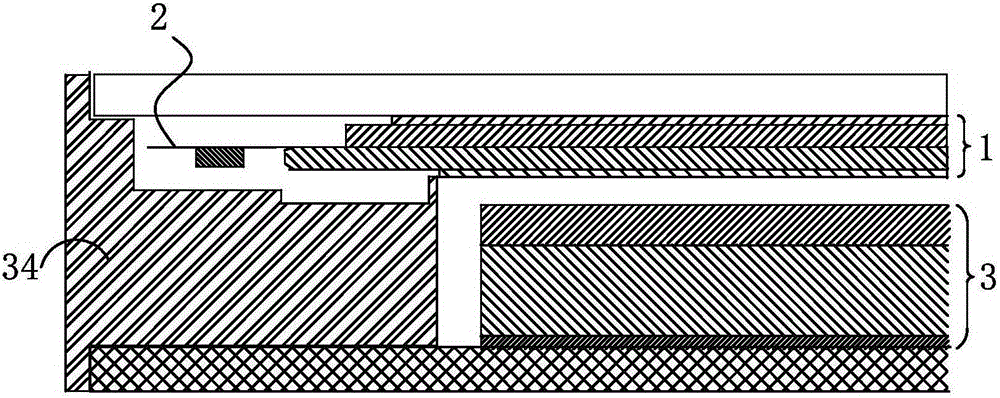

[0042]The invention provides a liquid crystal display device, comprising a liquid crystal screen, a grid COF structure arranged on the side of the liquid crystal screen, a backlight module arranged behind the liquid crystal screen, and a backlight module arranged on the liquid crystal screen and the backlight The front frame outside the module; wherein, one end of the grid COF structure is connected to the side of the liquid crystal screen, and is bent from the side of the liquid crystal screen toward the back of the liquid crystal screen, so that the grid The other end of the COF structure is connected to the back of the liquid crystal screen, the backlight module is located behind the grid COF structure, the front frame is located outside the bend of the grid COF structure, and the liquid crystal screen , the backlight module and the front frame jointly enclose and form an accommodating space for accommodating the gate COF structure.

Embodiment 2

[0044] combine Figure 4 , Figure 5 , Figure 6 As shown, this embodiment provides a liquid crystal display device, including a liquid crystal screen 1, a grid COF structure 2 arranged on the left and right sides 11 of the liquid crystal screen 1, a backlight module 3 arranged behind the liquid crystal screen 1, and a backlight module 3 arranged on the backlight The backplane 4 behind the module 3 and the front frame 5 arranged on the left and right sides of the liquid crystal screen 1, the backlight module 3 and the backplane 4, the liquid crystal screen 1, the backlight module 3 and the backplane 4 are combined together, and the left and right sides The combination is fixed by the front frame 5.

[0045] It can be understood that the liquid crystal display device also includes a top cover arranged on the top of the liquid crystal screen, backlight module and backplane, and the liquid crystal screen, backlight module and backplane are combined together, and the top is comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com