Film covering device for concrete column construction

A film-covering device and a technology of concrete columns, which are applied in the field of concrete columns, can solve problems such as needing to be replaced and reduce use costs, and achieve the effects of reducing use costs, reducing the probability of accidents, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

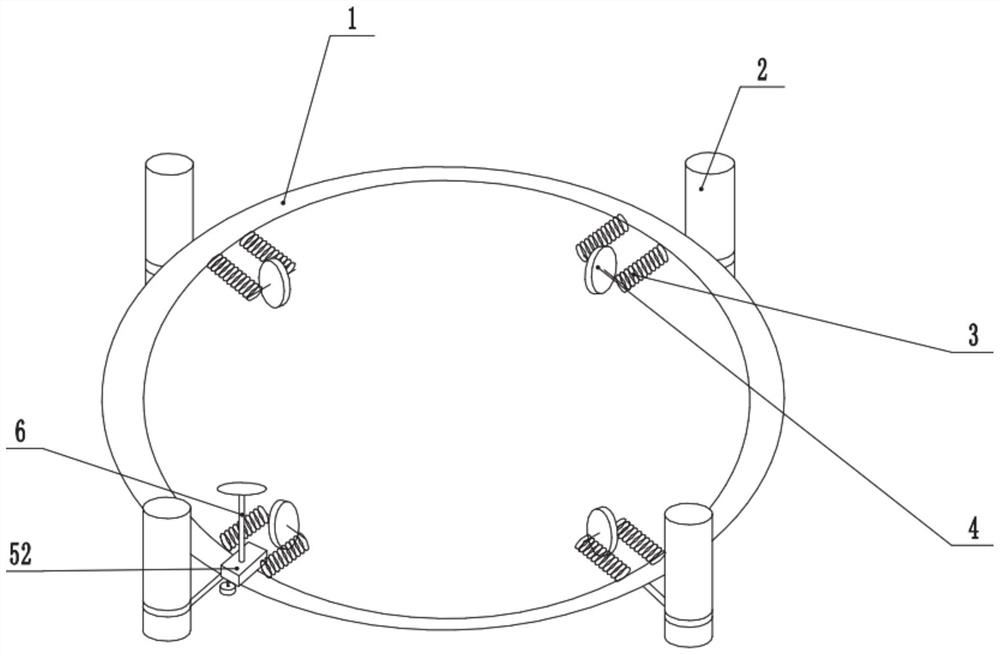

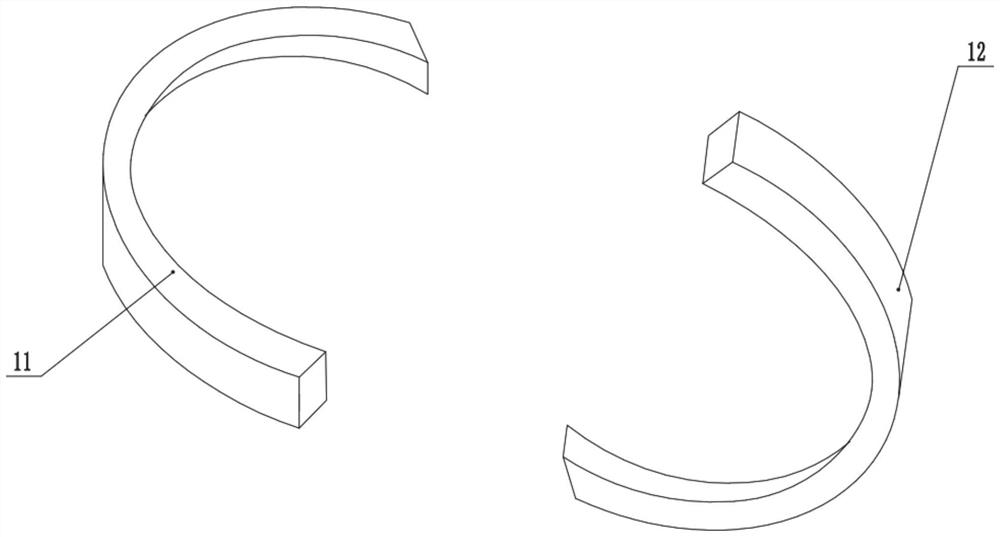

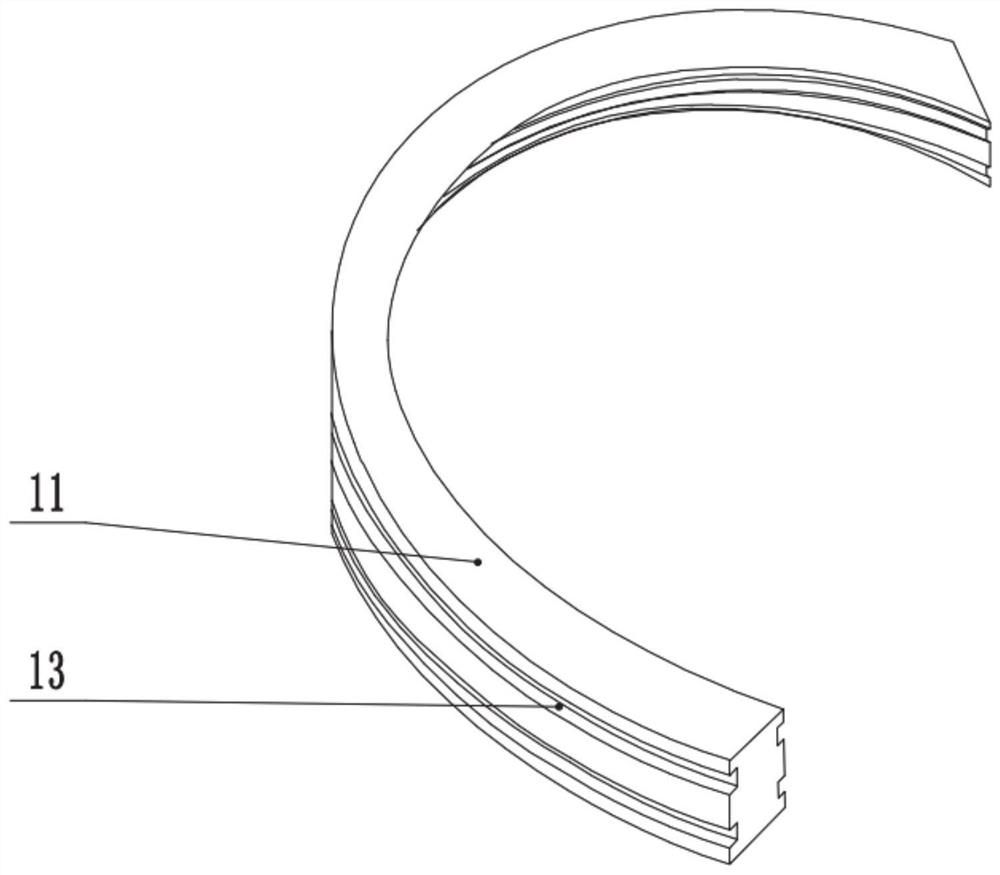

[0029] In a typical implementation of the present invention, this embodiment discloses a film covering device for concrete column construction, please refer to figure 1 , figure 2 , Figure 4 and Figure 5 , the device includes a track 1, a car body 52 and a film-coated shaft 6, the track 1 is annular, the track 1 is used to accommodate the concrete column, the track 1 is arranged on the outside of the concrete column 100, and can reciprocate along the central axis of the concrete column 100 , so as to reach every place on the surface of the concrete column 100; the track 1 includes a plurality of connected sub-tracks, and the inner side of each sub-track is elastically connected to the roller 4, and the straight line where the rotation axis of the roller 4 is located cuts the track 1, and the rolling surface of the roller 4 Keep in contact with the concrete column all the time. What needs to be explained here is that during the working process of this embodiment, the concr...

Embodiment 2

[0051] In a typical implementation of the present invention, this embodiment discloses a film covering device for concrete column construction. The difference from Embodiment 1 is that in this embodiment, there are two car bodies 52, In this embodiment, the two car bodies 52 are respectively named as the first car body 52 and the second car body 52, the first car body 52 runs on the top surface of the track 1, and the second car body 52 runs on the bottom surface of the track 1, The connection between the vehicle body 52 and the track 1 also adopts the way that the wheel body 51 clamps the track 1 .

[0052] Since two car bodies 52 need to be arranged in the present embodiment, wherein the car body 52 positioned at the top side can be arranged on the top side of the track 1 by gravity, while the car body 52 positioned at the bottom side may be separated from the track 1 under the influence of gravity, In order to further stabilize the connection between the car body 52 and the...

Embodiment 3

[0056] In a typical implementation of the present invention, this embodiment discloses a concrete column coating method, using the coating device for concrete column construction as described in Example 1 or Example 2, including the following steps:

[0057] A plurality of sub-tracks are spliced to form a track 1 sleeved on the surface of the concrete column 100, and the track 1 is lowered to the bottom of the main body of the concrete column 100;

[0058] The film roll is set on the film-coated shaft 6, the baffle plate 7 is fixed on the film-coated shaft 6 to prevent the film roll from breaking away from the film-coated shaft 6, and the starting position of the film roll is fixed on the concrete column;

[0059] Set the moving speed of the roller 4 and the moving speed of the car body 52, start the roller 4 and the car body 52;

[0060] The track 1 moves upward along the axial direction of the concrete column 100, and at the same time, the vehicle body reciprocates in circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com