A real-time performance evaluation method for single-loop control systems in tobacco processing

A single-loop control and processing technology, applied in electrical testing/monitoring, etc., can solve the problems of limited identification methods, affecting the accuracy of performance evaluation, and low accuracy of the model obtained from identification, so as to improve accuracy and real-time performance, and improve The performance evaluation level and the effect of improving the recognition sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

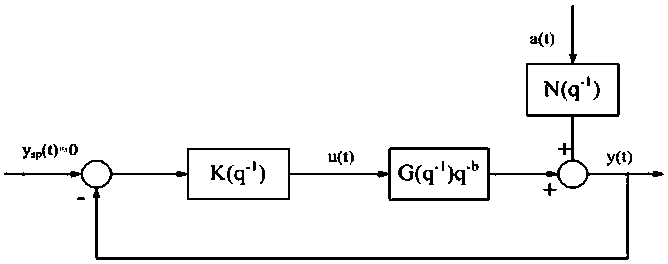

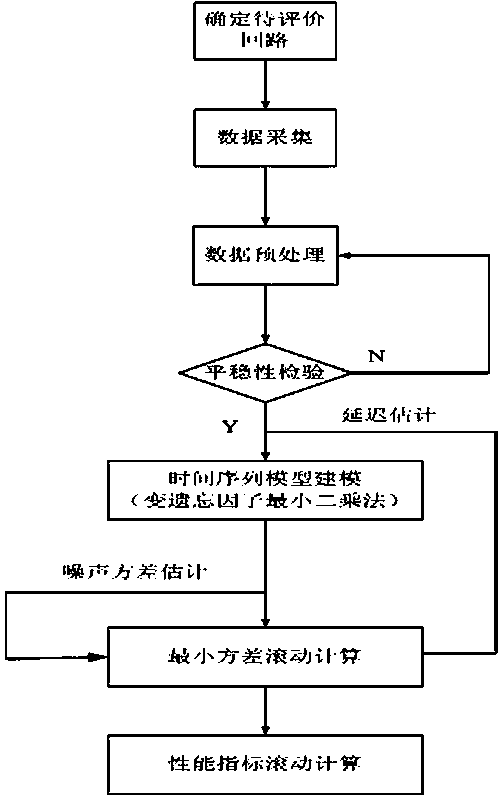

[0047] Taking the moisture control circuit of the SH93 airflow drying machine (scale flow rate before drying: 5100kg / h) in a cigarette factory as the evaluation object (the control system is as follows: figure 1 shown). The specific implementation steps are as follows (such as image 3 shown):

[0048] (1) Select the moisture control circuit as the evaluation object; determine the controlled variable (operation data) as the moisture at the outlet of the dried silk;

[0049] (2) After a certain brand of shredded tobacco completely enters the shred dryer, after the system runs stably for 5 minutes, take the moisture data of the shredded tobacco at outlet 10 minutes later to start rolling real-time performance evaluation. The length of the evaluation data is 120 (the sampling time is 10 seconds), the range of evaluation data is the data within 60 minutes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com