Experimental data processing method of structural detail fatigue rating experiment

A technology for experimental data processing and structural details, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to achieve clear processing, wide application range, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

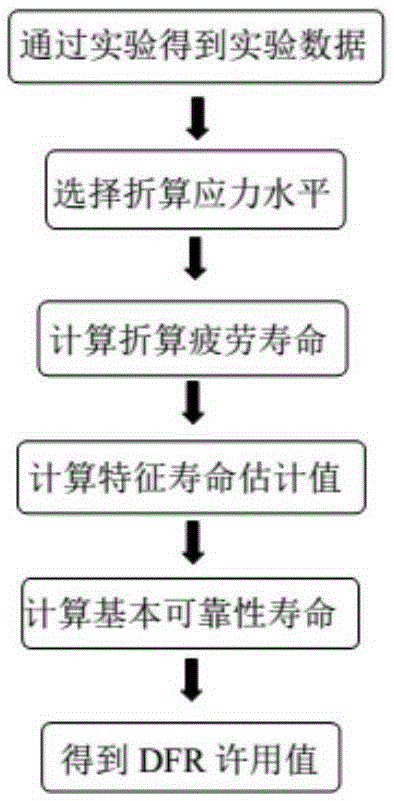

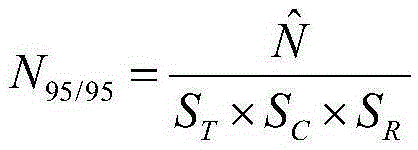

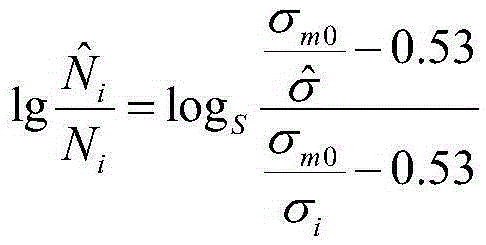

Method used

Image

Examples

Embodiment 1

[0052] The structure in which a certain web is connected to multiple columns is made of aluminum alloy. According to the test requirements of the present invention, the experimental data of multiple test pieces have been obtained (see Table 1), but the stress levels of each test piece are different. , now it is necessary to calculate the allowable DFR value of the assessment site.

[0053] The specific implementation includes the following steps:

[0054] Step 1, the experiment meets the requirements of the present invention, and the specific data are shown in the table below.

[0055] Table 1. Experimental data

[0056]

[0057] Among them, there are 5 specimens with expected failure in the assessed parts.

[0058] Step 2, calculate the average stress level of the 11 specimens in Table 1, with

[0059] 1 n Σ i = 1 n σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com