Underground storage silo for storing nuclear power plant fuel storage tank

A technology for underground storage and fuel, applied in the field of dry storage of spent fuel in nuclear power plants, can solve problems such as exceeding the allowable value of regulations, occurrence of accident conditions, complicated production process, etc., to improve storage safety, avoid functional failure, and heat transfer. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

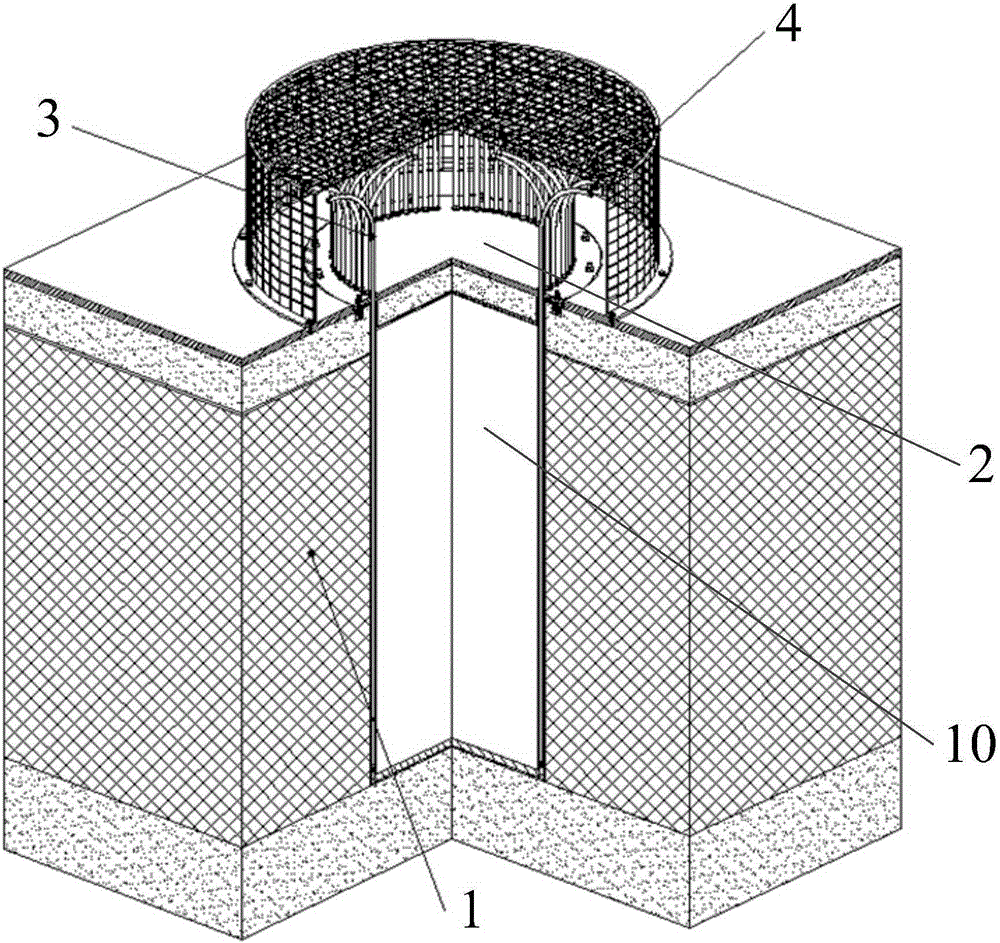

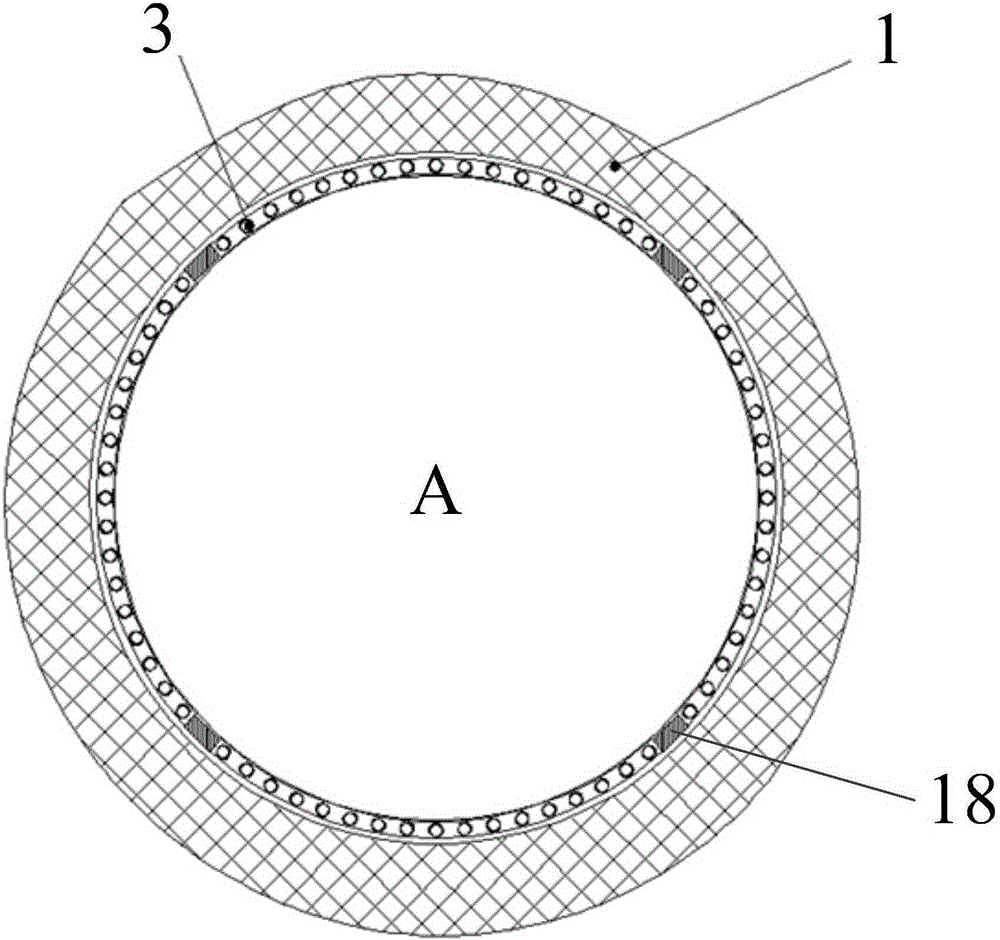

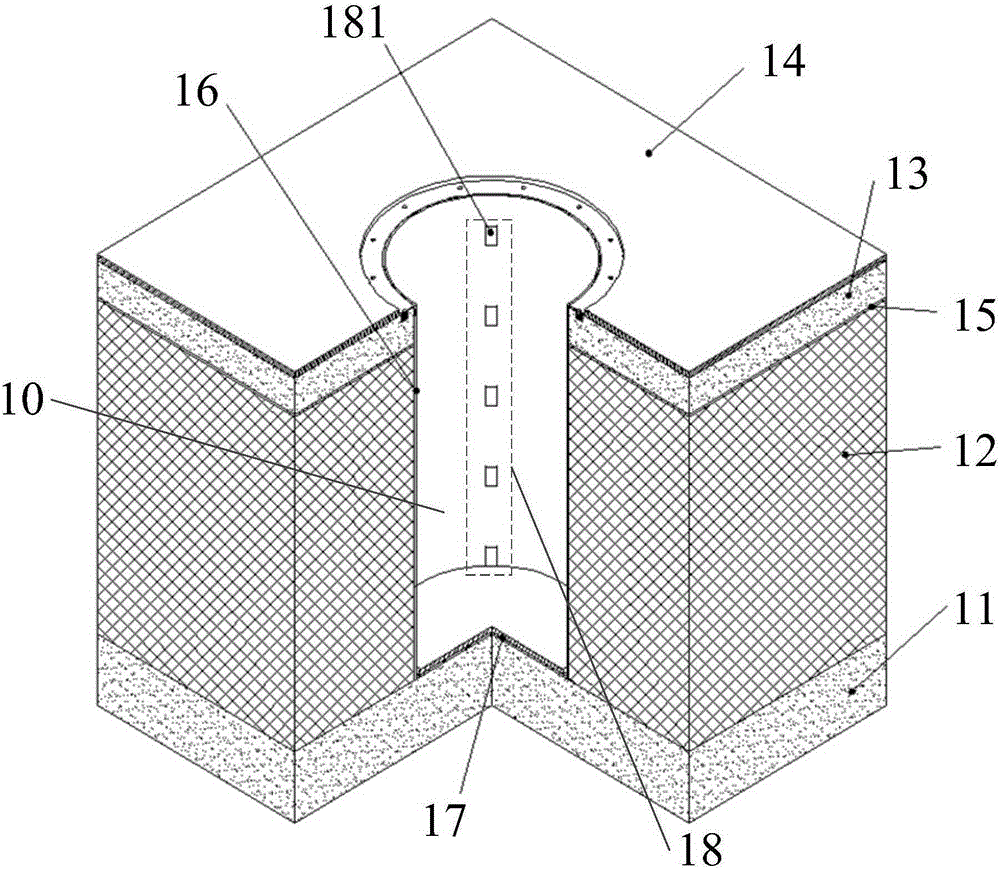

[0048] The embodiment of the present application provides an underground storage silo for storing fuel storage tanks of nuclear power plants, which solves the problem of storing fuel storage tanks on the ground in the prior art, which requires a large area, high cost, complex heat release process, and the existence of release silos. Accident conditions caused by hot pipes being blocked, concrete vertical silos may be overturned in earthquakes, etc., and easy access, etc., reduce the cost of building storage silos, and the fuel storage tanks are sealed in the underground storage chamber as a whole , there will be no flooding, earthquake overturning and other working conditions, and at the same time avoid the failure of the silo function caused by these working conditions, which greatly improves the storage safety of the fuel storage tank. In addition, the heat pipe transfers the heat released by the fuel storage tank to the atmosphere in a passive manner. Since the heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com