Electric-thermal separated, LED chip integrated and high-reflectivity circuit board and manufacture method thereof

A LED chip, electrothermal separation technology, applied in the direction of printed circuits, circuits, and electrical components connected with non-printed electrical components, can solve the problems of occlusion, reduced luminous efficiency, and reduced thermal conductivity, so as to increase luminous efficiency, improve Luminous efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be further described with reference to the drawings and specific embodiments.

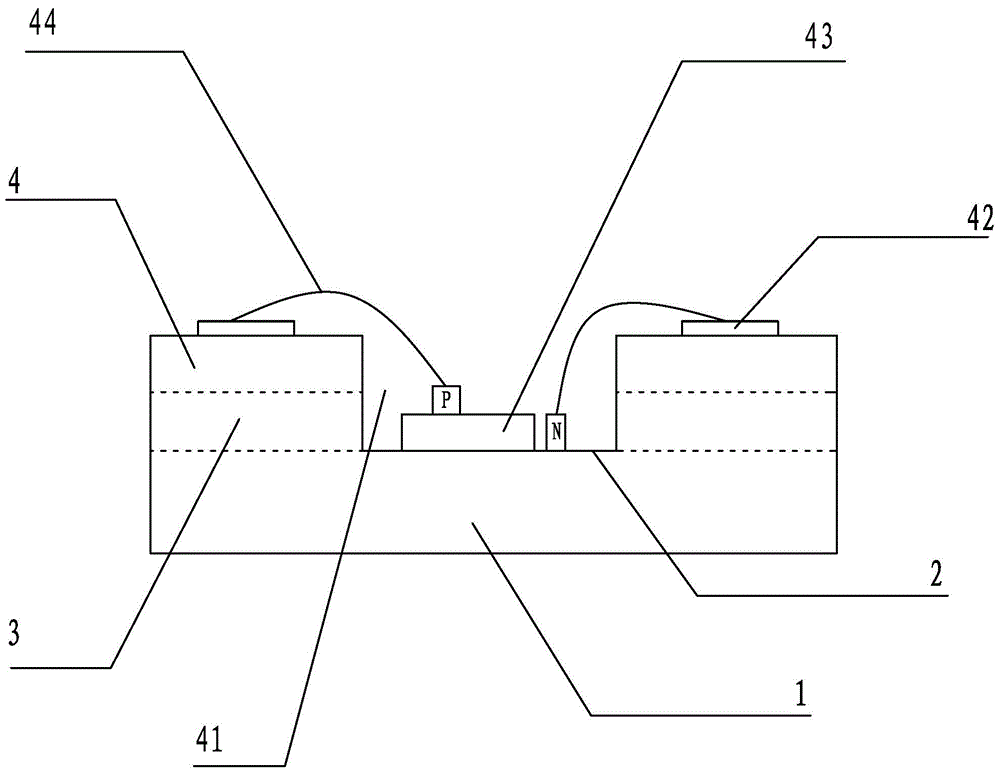

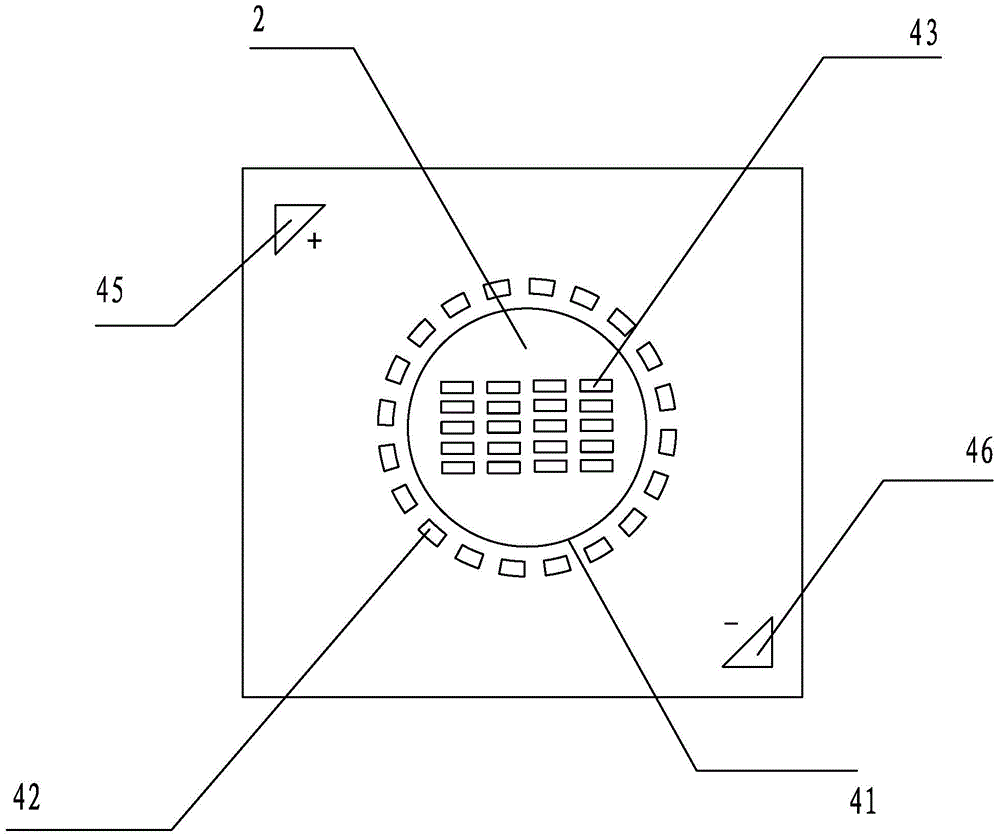

[0027] reference figure 1 , figure 2 . High-reflectivity circuit board with electrothermal separation and integration of LED chips, including:

[0028] The heat dissipation layer 1, the insulating layer 3, and the circuit layer 4 are laminated in sequence; the side of the heat dissipation layer 1 that contacts the insulating layer 3 is mirror aluminum 2; the circuit layer 4 is provided with at least one connected to the mirror aluminum 2 hole 41; in this embodiment, the material of the circuit layer 4 is copper foil; the material of the insulating layer 3 is epoxy.

[0029] At least one LED chip 43 is mounted on the mirror aluminum 2 located in the hole 41;

[0030] At least one LED solder joint 42 is provided on the circuit layer, and the LED solder joints 42 are independent of each other and arranged outside the hole 41; the P pole and the N pole of the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com