Power battery cooling structure and power battery thermal management system

A thermal management system, power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of small battery contact area, insufficient battery heat exchange, low heat exchange efficiency, etc., to improve charging and discharging efficiency, The effect of improving battery life and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

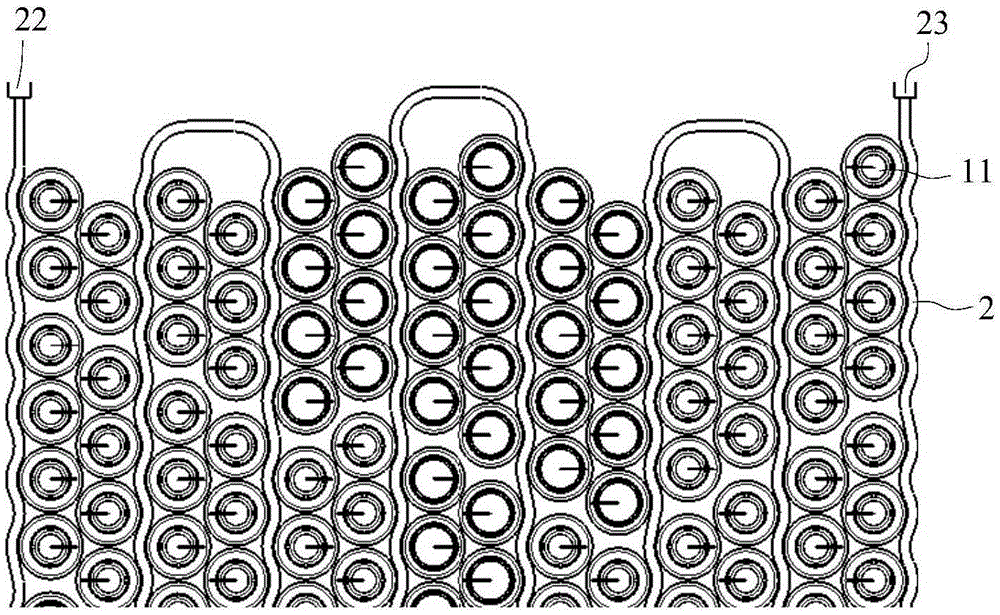

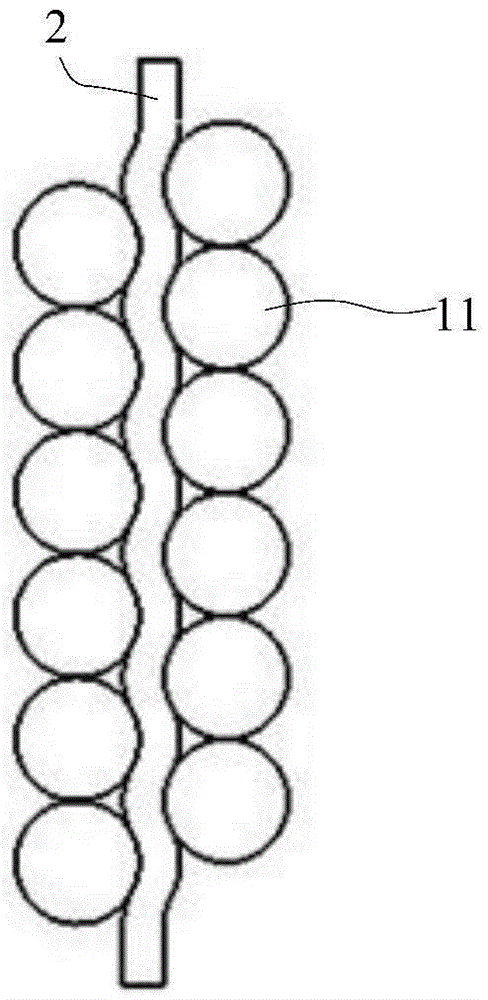

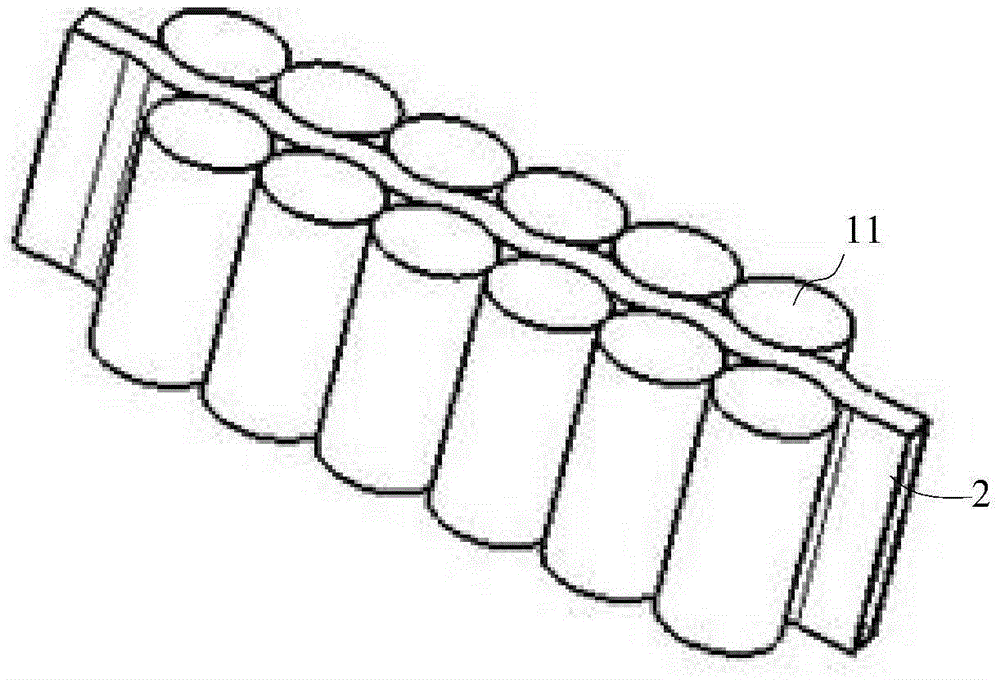

[0023] see Figure 1-Figure 6 , the present invention provides a power battery cooling structure, including a power battery 1 and a water jacket 2, the power battery 1 is composed of a number of battery cells 11 to form a module, and the battery cells 11 form intervals in the module, and the water The jacket 2 passes through the gap and is coiled in the module. Inside the module, according to the number and arrangement of the battery cells 11, the water jacket 2 is serpentinely wound on the surface of single or multiple rows of batteries. The water jacket 2 has a lumen 21, and the two ends of the lumen 21 form a water inlet 22 and a water outlet 23. The water jacket 2 has an outer surface that can be closely attached to the battery cell 11. The battery cell 11 All are cylindrical batteries, and the outer surface of the water jacket 2 has an arc surface that can closely fit with the cylindrical batteries. The surface of the water jacket 2 is made into arc surfaces with differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com