Large flat-top box-type transformer station housing structure

A kind of box-type substation, shell technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

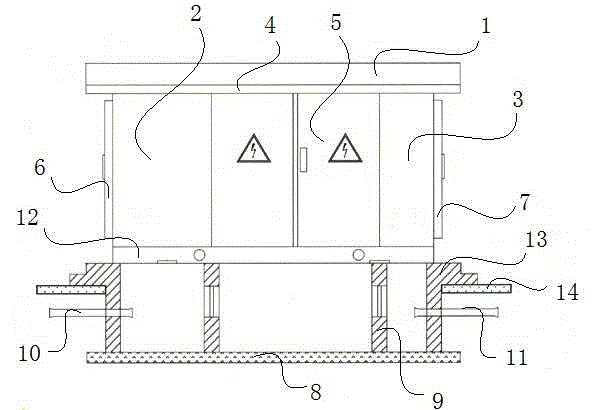

[0021] Such as figure 1 As shown, a large-scale flat-top box-type substation shell structure includes: an above-ground cabinet body and an underground structure. , is composed of a double-leaf door 5 and a bottom plate 12 arranged between the high-voltage chamber 2 and the low-voltage chamber 3, a transformer is arranged between the high-voltage chamber 2 and the low-voltage chamber 3, and the bottom plate 12 is a steel plate.

[0022] The underground structure includes: a concrete base 13 surrounding the underground of the substation shell and a base 8 arranged at the lower end of the concrete base 13, a filler layer 4 is set on the lower layer of the box top 1, and the high-voltage chamber entrance 6 / The low-voltage chamber entrance 7 is arranged on both sides of the cabinet body on the ground, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com