Filament burnout alarm device

A technology of alarm device and broken wire, applied in the direction of alarm device, lighting device, electric lamp circuit arrangement, etc., can solve the problems of endangering driving safety, increasing project investment, reducing driving efficiency, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

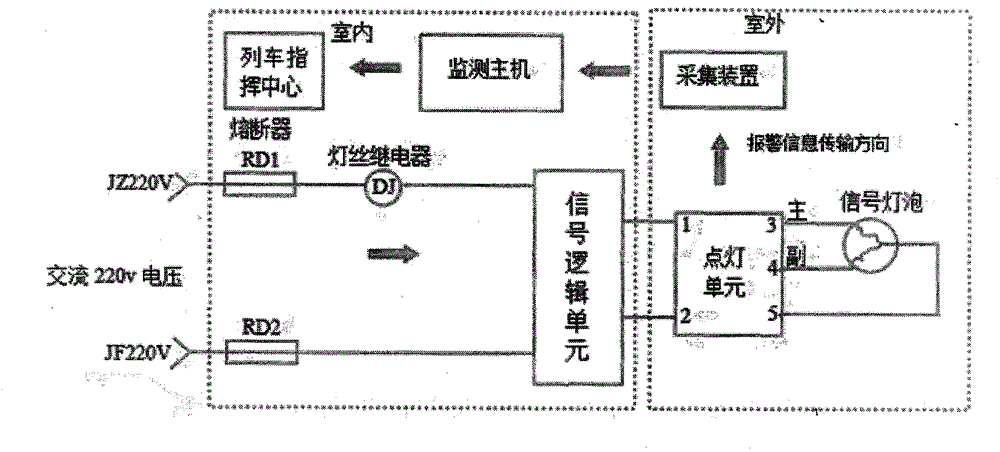

[0020] like figure 1 Shown: the present invention includes a signal logic unit, a lighting unit, a signal bulb, a collection device, a monitoring host, a train command center, a filament relay, a first fuse and a second fuse, and the first fuse and the second The fuses are respectively connected to the 220V power supply, the first fuse is connected to the signal logic unit after being connected in series with the filament relay, the second fuse is connected to the signal logic unit, and the signal logic unit is connected to the signal logic unit The first end of the lighting power supply is connected to the second end, the third end and the fourth end of the lighting unit are respectively connected to the first end and the second end of the signal light board, and the fifth end of the lighting unit connected to the control terminal of the signal bulb, the alarm signal outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com